Preparation method for transparent super hydrophobic polymer thin films

A polymer film, super-hydrophobic technology, applied in the field of transparent super-hydrophobic polymer film, can solve the problems of long cycle and harsh film-forming conditions, and achieve the effects of simple method, low price and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

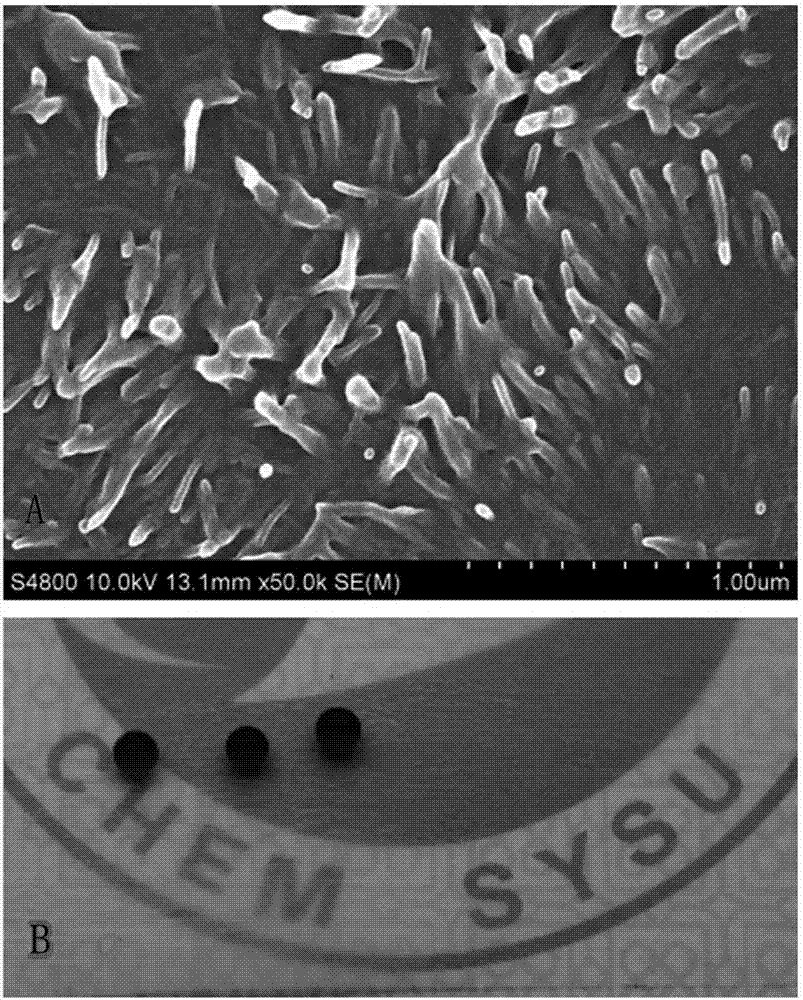

[0027] Take a tape-cast polypropylene (PP) film (thickness 20 μm), the front and back sides are bonded with two polyimide films (PI) of the same size to form a sandwich structure, and the PI-PP-PI film is clamped with a clip. Four sides, in order to keep the stability of film sandwich structure.Put it in the autoclave, in the pressure is 18MPa, the temperature is the supercritical CO of 140 ℃ 2 Soak in the middle for 30min, and then reduce the pressure quickly (pressure release rate: 6MPa / s), foam the polypropylene film, and form such as on the surface of the polypropylene film figure 1 A shows the nanomastoid structure. The water contact angle test shows that the contact angle reaches 155° after foaming, figure 1 B shows the situation that the film is transparent and super-hydrophobic. The visible light transmittance of the film measured by a UV-visible spectrophotometer reaches 76%, which is 86.4% of the light transmittance of the original film. The tensile property of the...

Embodiment 2

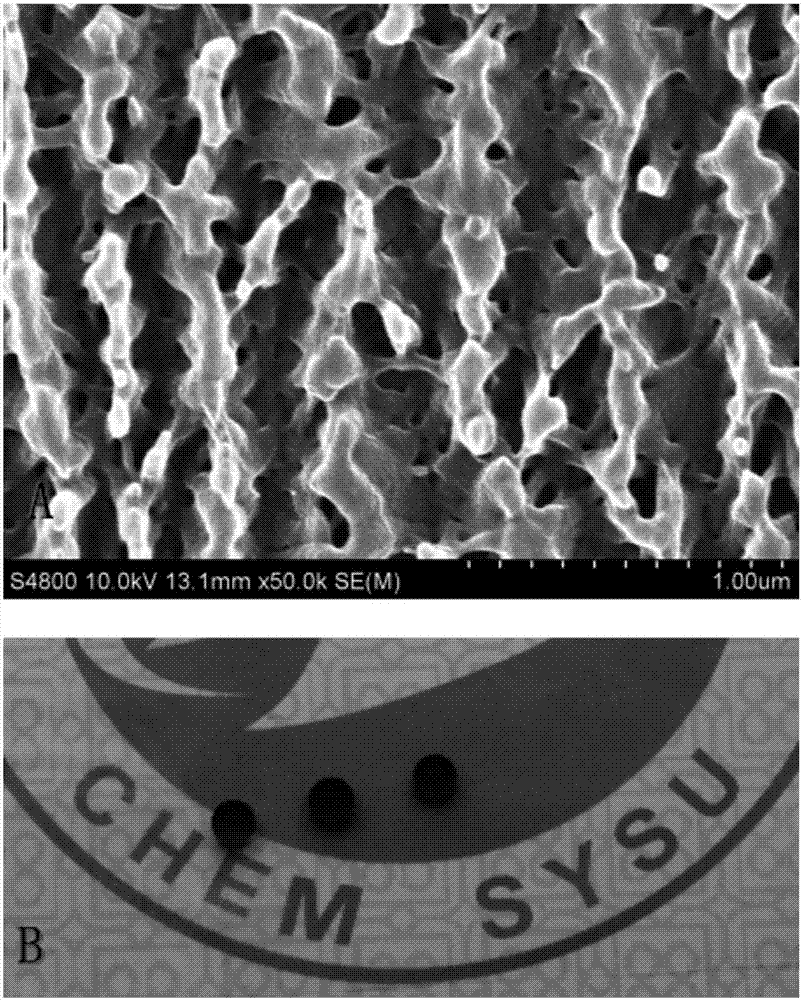

[0029] Take a biaxially stretched polypropylene film (thickness 30 μm), attach two PI films of the same size on the front and back sides to form a sandwich structure, and clamp the four sides of the PI film with clips to keep the PI film-PP film-PI Stabilization of thin film sandwich structures. Put it in a high-pressure reactor, at a pressure of 18MPa and a temperature of 145°C in supercritical CO 2 Immerse in the medium for 120min, and then quickly reduce the pressure (pressure release rate: 5MPa / s), foam the polypropylene film, and form on the surface such as figure 2 A shows the nanotrench structure. The water contact angle test shows that the contact angle reaches 158° after foaming, figure 2 B shows the situation that the film is transparent and super-hydrophobic. The visible light transmittance of the film is 88% as measured by the UV-Vis spectrophotometer, which is 97.7% of the original film. The tensile property of the polypropylene film is 43.6MPa, which is 96% ...

Embodiment 3

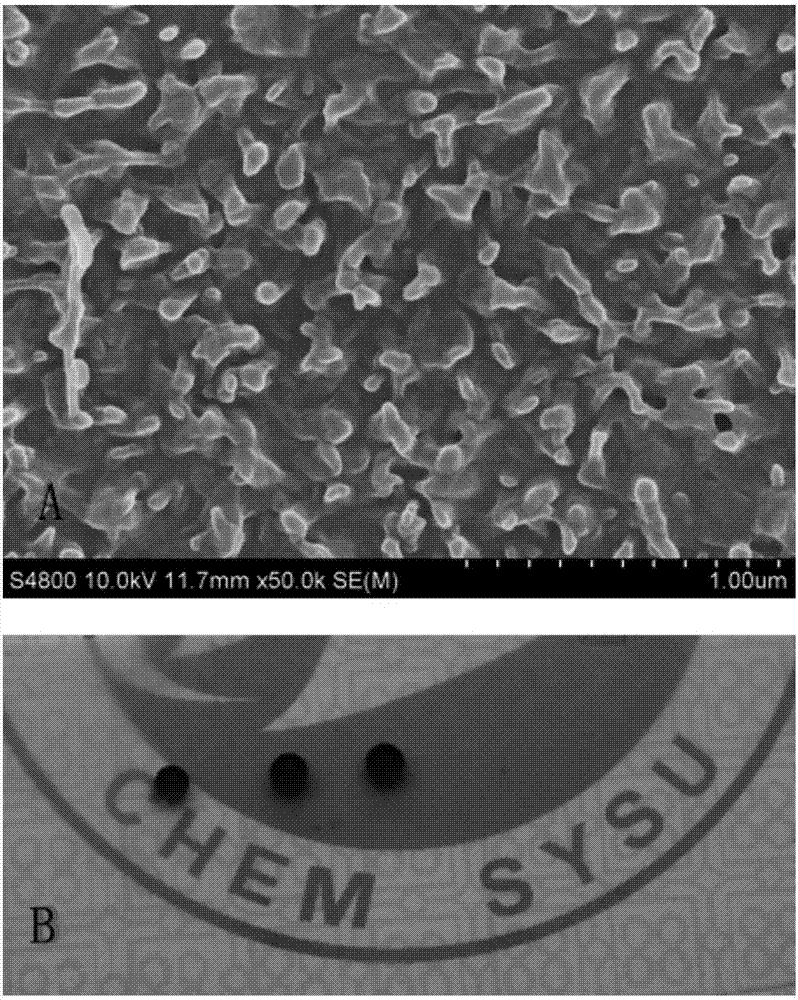

[0031] Take a tape-cast polyethylene terephthalate film (PET, thickness 100 μm), attach the front and back sides to two PI films of the same size to form a sandwich structure, clamp the four sides of the PI film with clips, and Keep the sandwich structure of PI film-PET film-PI film stable. Put it in a high-pressure reactor, at a pressure of 25MPa and a temperature of 160°C supercritical CO 2 Immerse in the medium for 180min, and then quickly reduce the pressure (pressure release rate: 6MPa / s), foam the polypropylene film, and form on the surface such as image 3 The nanomastoid structure of A. The water contact angle test shows that the contact angle reaches 153° after foaming, image 3 The film shown in B is transparent and super-hydrophobic. The visible light transmittance of the film measured by an ultraviolet-visible spectrophotometer reaches 82%, and the light transmittance of the original film remains 93.4%. The tensile property of the PET film is 198MPa, which is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com