Polymer-based ceramic ultrafiltration composite coating material as well as preparation method and application thereof

A composite coating and polymer technology, applied in the field of membrane separation, can solve the problems of unfavorable separation membrane service life, low strength, weak binding force, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

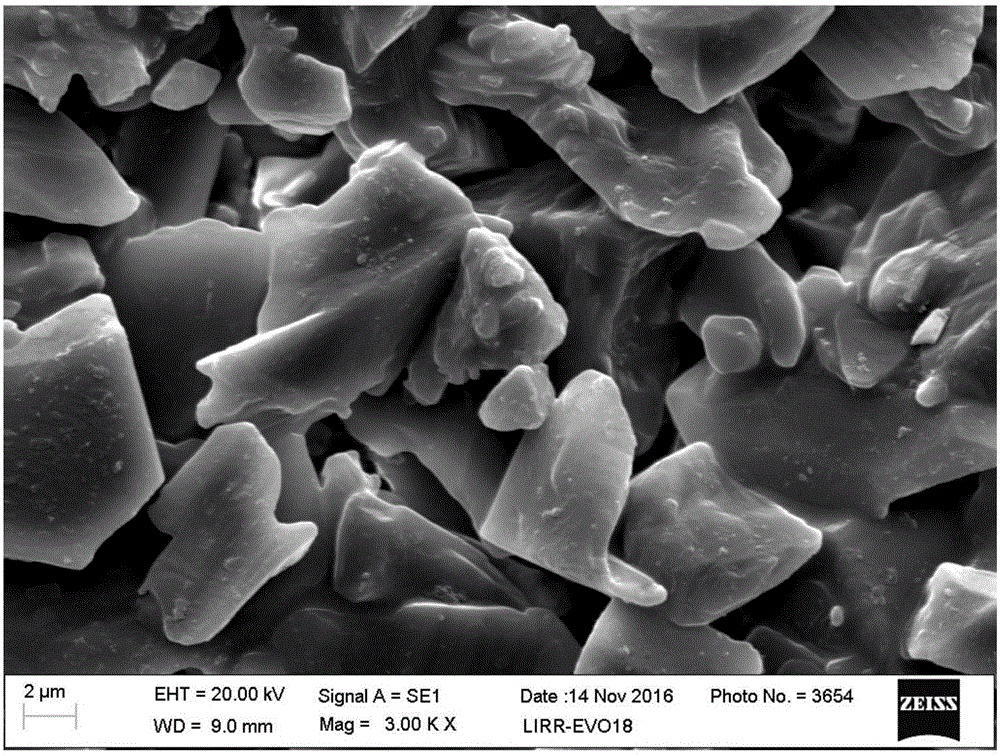

[0051] The polymer-based ceramic ultrafiltration composite coating material of this embodiment includes a ceramic base film, and the surface of the ceramic base film is sequentially provided with a silane coupling layer and a polyimide layer from the inside to the outside; the ceramic base film, the silane coupling layer 1. The mass ratio of the polyimide layer is 1:0.001:0.01; the ceramic base film is aluminum oxide ceramic film, and the silane coupling layer is γ-aminopropyltrimethoxysilane.

[0052] The preparation method of the polymer-based ceramic ultrafiltration composite coating material of the present embodiment comprises the following steps:

[0053] 1) Put a commercial aluminum oxide ceramic membrane with a size of 1cm×1cm (mass 2g) into a beaker filled with acetone, clean it in an ultrasonic cleaner for 5 minutes, take it out and put it into a beaker filled with absolute ethanol, Wash in an ultrasonic cleaner for 5 minutes, take it out and put it into a beaker fill...

Embodiment 2

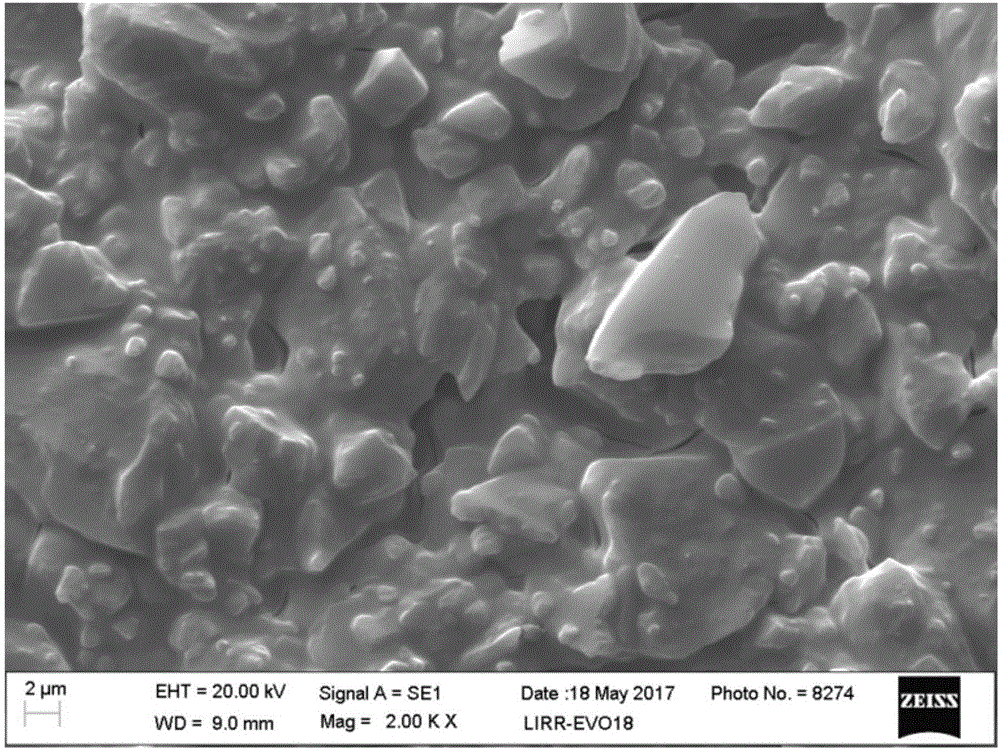

[0056] The polymer-based ceramic ultrafiltration composite coating material of this embodiment includes a ceramic base film, and the surface of the ceramic base film is sequentially provided with a silane coupling layer and a polyimide layer from the inside to the outside; the ceramic base film, the silane coupling layer 1. The mass ratio of the polyimide layer is 1:0.005:0.05; the ceramic base film is aluminum oxide ceramic film, and the silane coupling layer is γ-aminopropyltrimethoxysilane.

[0057] The preparation method of the polymer-based ceramic ultrafiltration composite coating material of the present embodiment comprises the following steps:

[0058] 1) Put a commercial aluminum oxide ceramic membrane with a size of 1cm×1cm (mass 2g) into a beaker filled with acetone, clean it in an ultrasonic cleaner for 10 minutes, take it out and put it into a beaker filled with absolute ethanol, Clean in an ultrasonic cleaner for 10 minutes, take it out and put it into a beaker f...

Embodiment 3

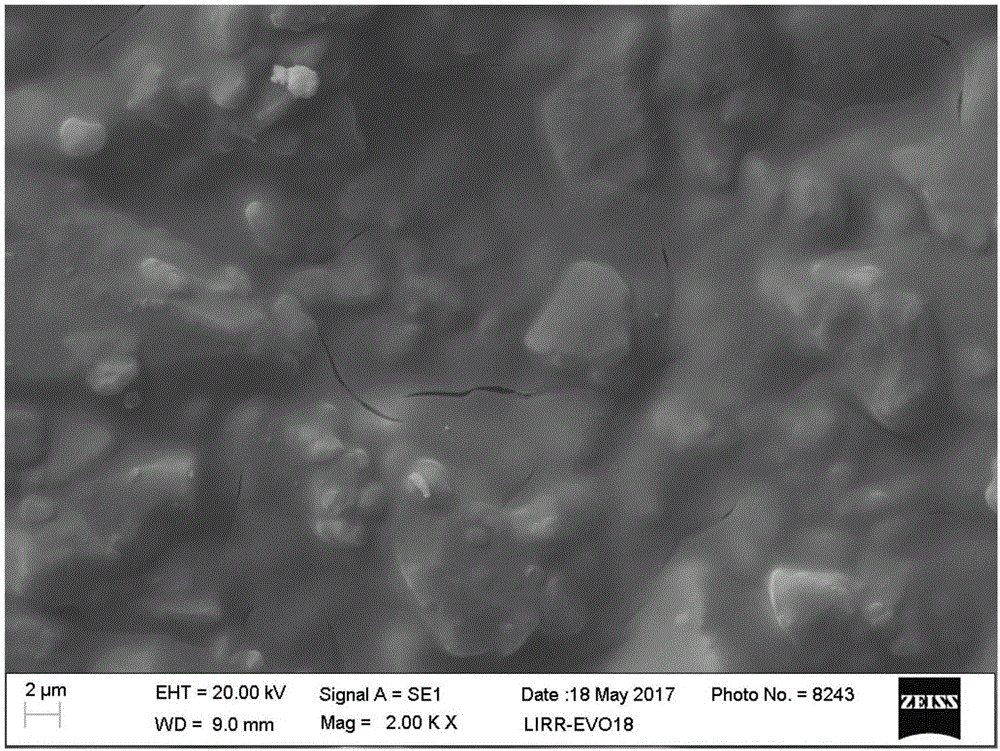

[0061] The polymer-based ceramic ultrafiltration composite coating material of this embodiment includes a ceramic base film, and the surface of the ceramic base film is sequentially provided with a silane coupling layer and a polyimide layer from the inside to the outside; the ceramic base film, the silane coupling layer 1. The mass ratio of the polyimide layer is 1:0.003:0.03; the ceramic base film is aluminum oxide ceramic film, and the silane coupling layer is γ-aminopropyltrimethoxysilane.

[0062] The preparation method of the polymer-based ceramic ultrafiltration composite coating material of the present embodiment comprises the following steps:

[0063] 1) Put a commercial aluminum oxide ceramic membrane with a size of 1cm×1cm (mass 2g) into a beaker filled with acetone, clean it in an ultrasonic cleaner for 7 minutes, take it out and put it into a beaker filled with absolute ethanol, Wash in an ultrasonic cleaner for 7 minutes, take it out and put it into a beaker fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Most probable aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com