Ionic liquid modified crosslinked porous chitosan adsorbent and preparation method and application thereof

A technology of porous chitosan and ionic liquid, applied in the direction of adsorption of water/sewage treatment, other chemical processes, chemical instruments and methods, etc., to achieve good stability, large adsorption capacity, and improved adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

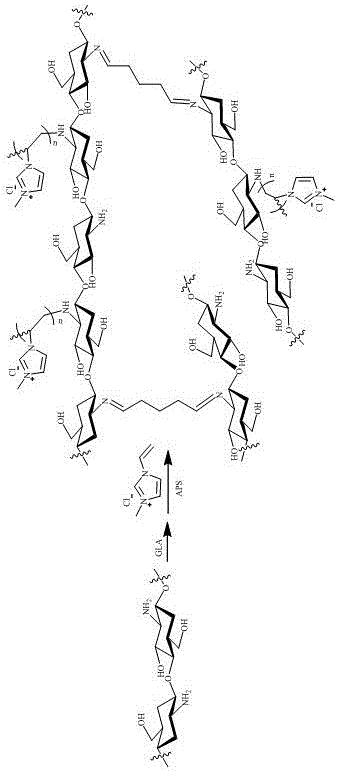

[0020] Preparation of Ionic Liquid Modified Crosslinked Porous Chitosan Adsorbent

[0021] (1) Synthesis of cross-linked porous chitosan: Dissolve 5 g of chitosan (CS) with 143 mL of acetic acid solution with a volume fraction of 1% by stirring and dissolving. After the chitosan is completely dissolved and rested until the air bubbles completely escape, a uniform shell can be obtained. Polysaccharide solution; Slowly add the prepared chitosan solution drop by drop into 10% sodium hydroxide solution with a 0.5 mL plastic dropper, stir magnetically at low speed for 3 h after the addition, and use Wash with deionized water until neutral, store in deionized water to obtain porous chitosan spheres (CB); the preparation of cross-linked porous chitosan (CCB) is to add 100 mL of chitosan spheres (CB) to 100 mL of deionized water and 2 mL of glutaraldehyde solution (GLA) with a volume fraction of 50% were stirred magnetically at 25 °C for 45 min; then washed several times with ethanol ...

Embodiment 2

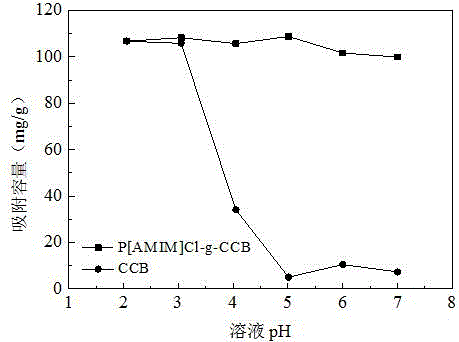

[0024] Effect of pH on Adsorption Properties of Ionic Liquid Modified Crosslinked Porous Chitosan Adsorbent

[0025] Through the static test of solutions with different pH values, the adsorption capacity was measured by ultraviolet spectrophotometry. figure 2 It is the variation of the adsorption capacity of ionic liquid modified cross-linked porous chitosan for adsorption of sunset yellow with the initial pH value of the solution. The initial sunset yellow concentration: 50 ppm; adsorbent dosage: 5 mg; adsorption time: 3 h; temperature: 25°C; sample volume: 10 mL.

Embodiment 3

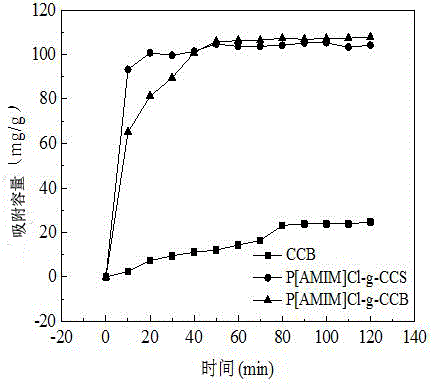

[0027] Optimization of adsorption time

[0028] Stirring time is of great significance to improve the adsorption efficiency. In this experiment, the influence of the adsorbent on the adsorption performance of sunset yellow in the case of 10-120 min was investigated, and the results are as follows: image 3 As shown, the adsorption capacity increased with the increase of adsorption time. In the initial stage, the adsorption of sunset yellow by the adsorbent was very fast. With the increase of adsorption time, the adsorption capacity of sunset yellow increased rapidly, and then the adsorption speed gradually slowed down. Finally, a plateau appeared, and the adsorption reached an equilibrium state at this time. In order to make the adsorption effect better and save the adsorption time, the adsorption time for the follow-up experiment of sunset yellow in this experiment was 60 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com