Composite flocculant as well as preparation method and application thereof

A composite flocculant and mixed solution technology, which is applied in dehydration/drying/concentrated sludge treatment, mining wastewater treatment, etc., can solve the problems of oily sludge with complex components, large component changes, poor flocculation effect, etc., and achieve reduction Treatment costs and operating costs, good water solubility, good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

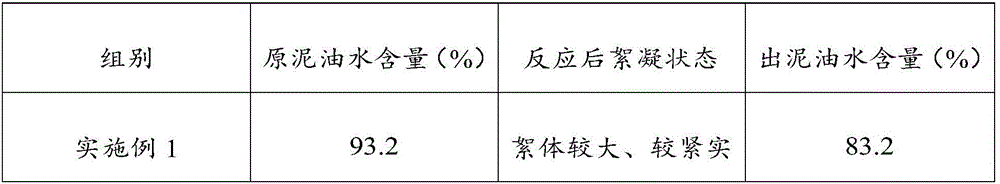

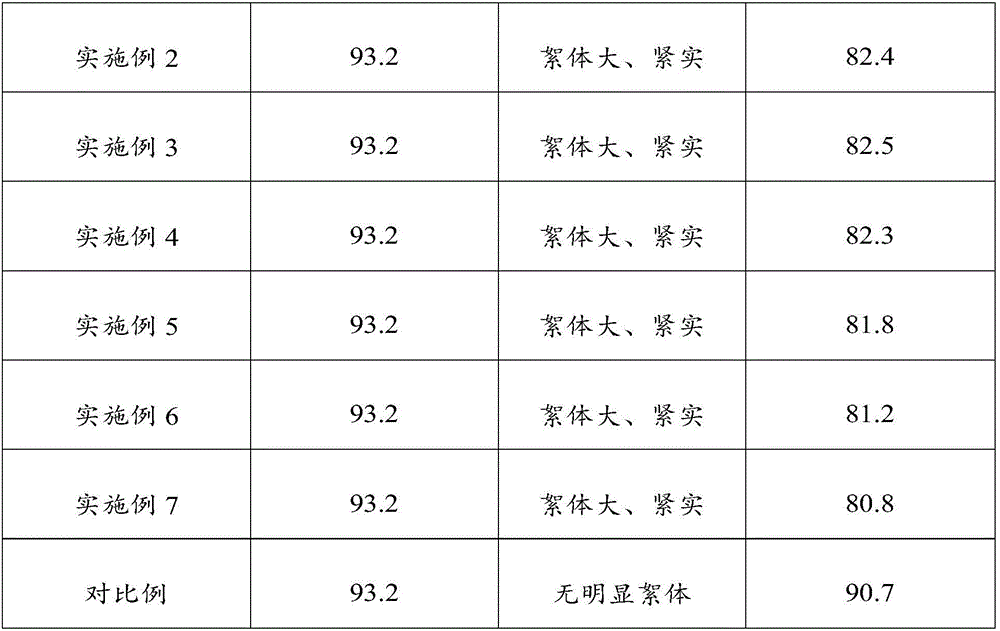

Examples

Embodiment 1

[0041] This embodiment provides a composite flocculant, which is made of various raw materials, in parts by weight, the various raw materials include 0.1 part of cationic polyacrylamide, 1.0 part of calcium chloride, 0.5 part of sodium silicate, and 8 parts of polymeric sulfuric acid aluminum and 0.5 part disodium edetate.

[0042] This embodiment also provides a method for preparing a composite flocculant, which includes the following steps: mixing 0.1 part of cationic polyacrylamide, 1.0 part of calcium chloride, 0.5 part of sodium silicate, 8 parts of polyaluminum sulfate and 0.5 part of ethylenediamine Disodium tetraacetate is dissolved in 1000 parts of water.

Embodiment 2

[0044] This embodiment provides a composite flocculant, which is made of various raw materials, in parts by weight, the various raw materials include 0.5 parts of cationic polyacrylamide, 2.5 parts of calcium chloride, 2.0 parts of sodium silicate, 20 parts of polymeric sulfuric acid Aluminum and 2.0 parts of disodium edetate.

[0045] This embodiment also provides a method for preparing a composite flocculant, which includes the following steps:

[0046] First, in parts by weight, 0.5 parts of cationic polyacrylamide is dissolved in water to obtain a cationic polyacrylamide aqueous solution with a mass fraction of 0.1%; a mixture of 2.0 parts of sodium silicate and 2.0 parts of disodium edetate is mixed with The cationic polyacrylamide aqueous solution was stirred and mixed to obtain a first mixed solution, wherein 18 g of the mixture was added to every liter of cationic polyacrylamide aqueous solution.

[0047] Secondly, 2.5 parts of calcium chloride, 20 parts of polyalumin...

Embodiment 3

[0050] This embodiment provides a composite flocculant, which is made of various raw materials, in parts by weight, the various raw materials include 0.3 parts of cationic polyacrylamide, 1.5 parts of calcium chloride, 0.8 parts of sodium silicate, 10 parts of polymeric sulfuric acid Aluminum and 1.0 parts disodium edetate.

[0051] This embodiment also provides a method for preparing a composite flocculant, which includes the following steps:

[0052] First, in parts by weight, 0.3 parts of cationic polyacrylamide is dissolved in water to obtain a cationic polyacrylamide aqueous solution with a mass fraction of 0.3%; a mixture of 0.8 parts of sodium silicate and 1.0 parts of disodium edetate is powdered After being purified to 150 mesh, it was stirred and mixed with an aqueous solution of cationic polyacrylamide to obtain the first mixed solution, wherein 40 g of the mixture was added to every liter of aqueous solution of cationic polyacrylamide.

[0053] Secondly, 1.5 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com