Room-temperature curing ethyl lactate removal type silicone sealant

A silicone sealant, ethyl lactate technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of pungent, corrosive odor of cement substrates, and slow deep curing. , to achieve the effect of moderate curing speed and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

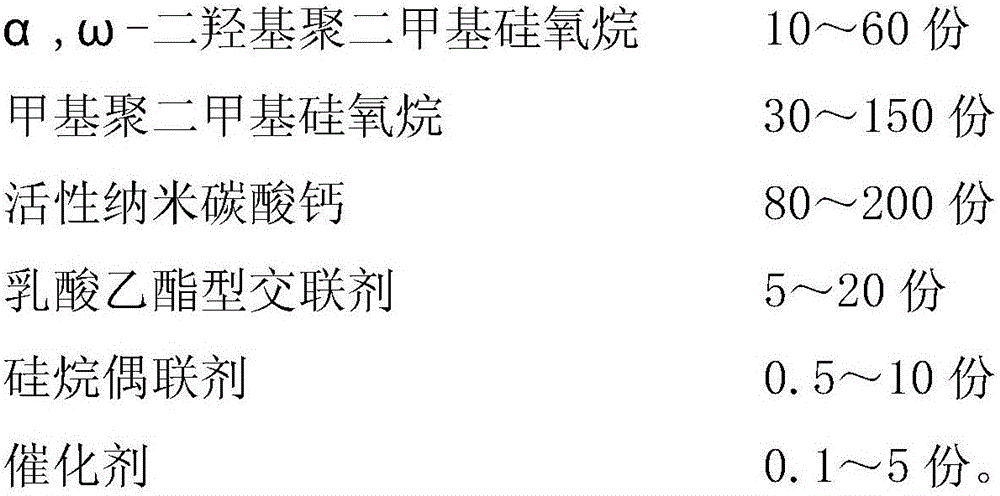

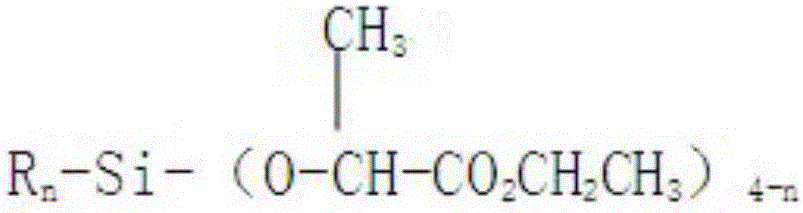

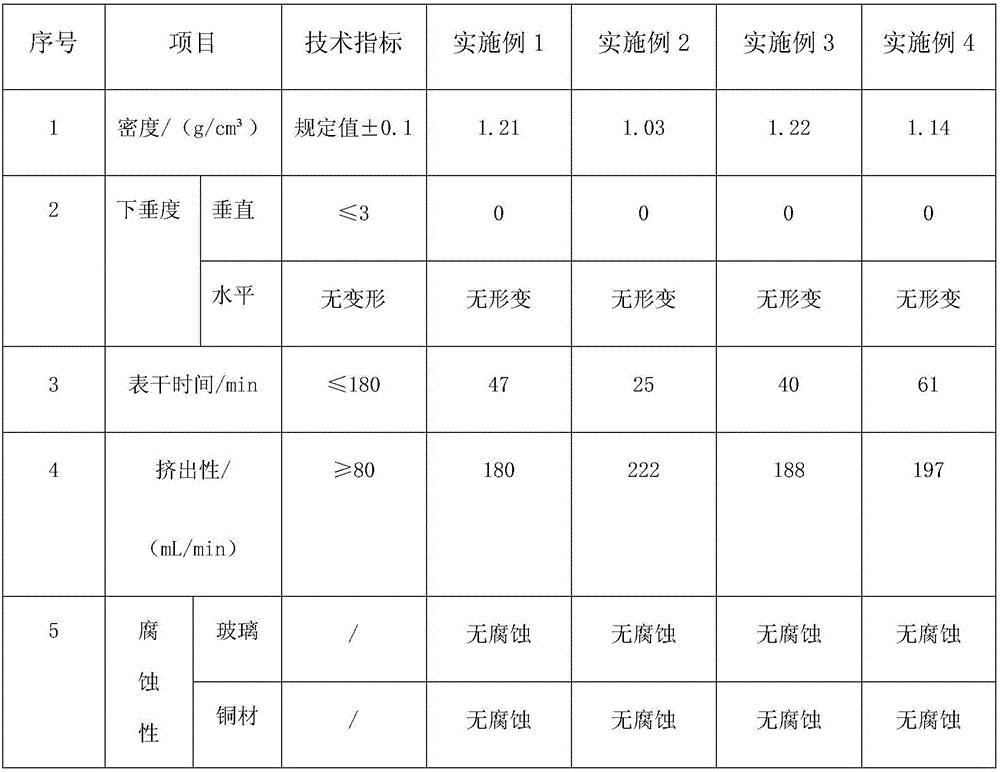

[0024] 40 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mPa.s at 25°C and 60 parts of methyl polydimethylsiloxane with a viscosity of 350mPa.s at 25°C are pre-dried Add 170 parts of active nano-calcium carbonate into the kneader and heat up to 110°C to 120°C, knead for 1.5 hours under the condition of vacuum degree of -0.09MPa, then cool down to room temperature, transfer the above materials to the planetary mixer, and then add methyl 13 parts of ethyl trilactate silane, 5 parts of 3-aminopropyltriethoxysilane, 0.3 part of dibutyltin dilaurate, mixed for 40 minutes at a vacuum degree of -0.09MPa and a speed of 35rpm to obtain a room temperature curing Ethyl lactate type silicone sealant (see Table 1 for performance test results).

Embodiment 2

[0026] 60 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 80000mPa.s at 25°C and 55 parts of methyl polydimethylsiloxane with a viscosity of 100mPa.s at 25°C are pre-dried Add 98 parts of active nano-calcium carbonate into the kneader and raise the temperature to 110°C~120°C, knead for 1.5 hours under the condition of vacuum degree of -0.09MPa, then cool down to room temperature, transfer the above materials to the planetary mixer, and then add vinyl 15 parts of ethyl trilactate silane, 7 parts of 3-aminopropyltriethoxysilane, 0.5 part of dibutyltin dilaurate, mixed for 40 minutes at a vacuum degree of -0.09MPa and a speed of 35rpm to prepare a room temperature curing Ethyl lactate type silicone sealant (see Table 1 for performance test results).

Embodiment 3

[0028] 40 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mPa.s at 25°C and 60 parts of methyl polydimethylsiloxane with a viscosity of 100mPa.s at 25°C are pre-dried Add 170 parts of active nano-calcium carbonate into the kneader and heat up to 110°C to 120°C, knead for 1.5 hours under the condition of vacuum degree of -0.09MPa, then cool down to room temperature, transfer the above materials to the planetary mixer, add methyl 8 parts of ethyl trilactate silane, 5 parts of vinyl trilactate ethyl silane, 5 parts of 3-aminopropyltriethoxysilane, 0.3 part of dibutyltin dilaurate, at a vacuum degree of -0.09MPa, at a speed of 35rpm After mixing for 40 minutes under the same conditions, a room temperature curing delactate type silicone sealant was prepared (see Table 1 for performance test results).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com