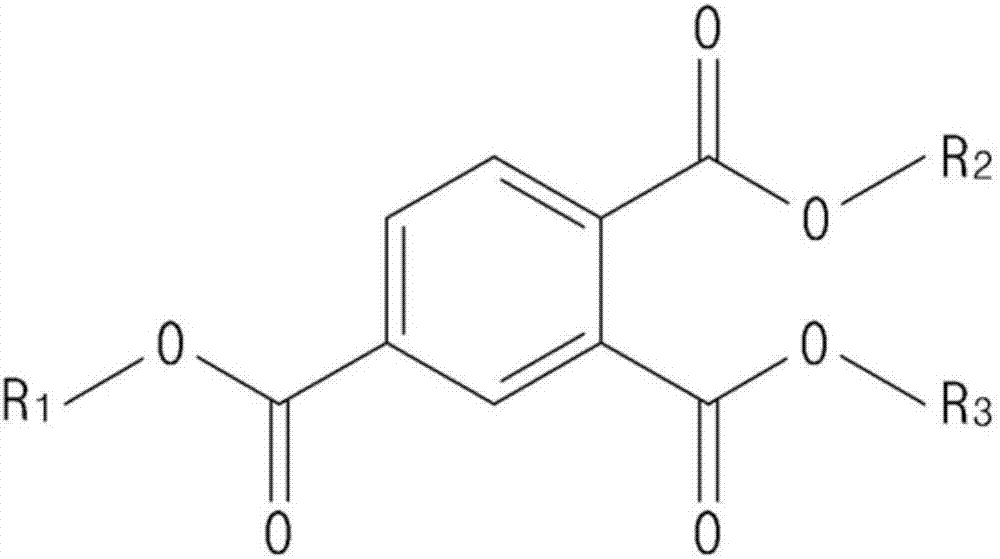

Plasticizer composition, resin composition, and methods for preparing same

A technology of resin composition and plasticizer, which is applied in the field of plasticizer composition to achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0027] Preparation Example 1: Preparation of ESO

[0028] Epoxidized soybean oil (ESO; purchased from SAJO) was used.

preparation Embodiment 2

[0029] Preparation Example 2: Preparation of Triisononyl Trimellitic Acid

[0030] Using 576.3 g of trimellitic acid (TMA) and 1,948 g of isononyl alcohol as reaction components, 1,731 g of a triisononyl trimellitate product was finally obtained (yield: 98%).

preparation Embodiment 3

[0031] Preparation Example 3: Preparation of the reaction product of C8 and C10 mixed alcohols and TMA

[0032] Using 576.3 g of TMA, 878.9 g of n-octanol and 1,068.5 g of n-decyl alcohol as reaction components, 1,731 g of a trimellitate product was finally obtained (yield: 98%).

[0033] Examples and comparative examples were prepared as follows.

[0034] [Table 1]

[0035]

[0036] [Table 2]

[0037]

Epoxidized oil

trimellitic acid esters

Mixing weight ratio

Comparative example 1

ESO

TEHTM

0.5:9.5

Comparative example 2

ESO

TINTM

0.7:9.3

Comparative example 3

ESO

Preparation Example 3

0.5:9.5

Comparative example 4

ESO

TEHTM

5:5

Comparative Example 5

ESO

TBTM

5:5

[0038]

[0039] Hardness measurement

[0040] Shore (Shore "D") hardness was measured at 25°C under the conditions of 3T and 10 s according to ASTM D2240.

[0041] Measurement of Tensile S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com