A modification method of sulfonic acid-based cation exchange resin and a method for preparing methyl tert-amyl ether

A technology of ion exchange resin and sulfonic acid group cation, applied in the direction of adding unsaturated compounds to prepare ether, ether preparation, chemical instruments and methods, etc. Achieve the effect of improving specific surface, improving stability and reducing loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

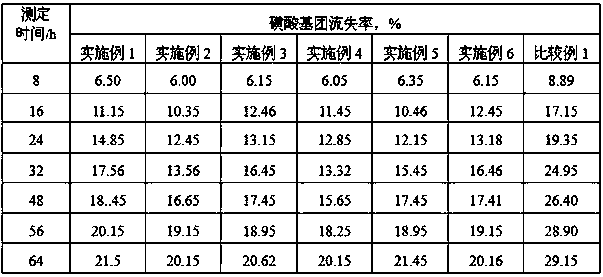

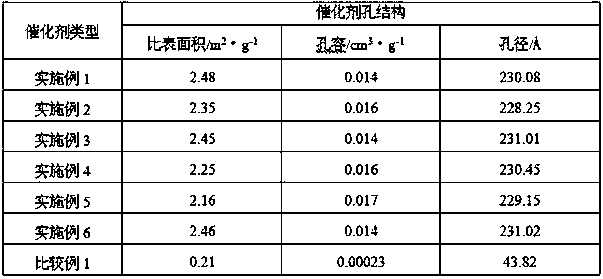

Examples

Embodiment 1

[0047] Modification of D72 type strong acid cation exchange resin (purchased from Dandong Mingzhu Special Resin Co., Ltd.): place D72 type strong acid cation exchange resin in isopropanol solvent, and the volume ratio of isopropanol to D72 type strong acid cation exchange resin is 3 : 1, Soak at 50°C for 24h, and then pass nitrogen gas in three stages, the first stage is at a pressure of 0.5MPa, temperature 60°C, and the flow rate of nitrogen gas is 1m 3 / h; the conditions for feeding nitrogen in the second stage are pressure 0.8MPa, temperature 80°C, nitrogen flow rate 3m 3 / h; the conditions for feeding nitrogen in the third stage are pressure 1.2MPa; temperature 100°C, nitrogen flow rate 6m 3 / h, the processing time of the three stages are 10 h, 16 h, 24 h respectively.

Embodiment 2

[0049] Except that isopropanol was replaced by ethanol, other conditions were the same as in Example 1, and the D72 type strong acid cation exchange resin catalyst was modified.

Embodiment 3

[0051] Except that isopropanol was replaced by methanol, other conditions were the same as in Example 1, and the D72 type strong acid cation exchange resin catalyst was modified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com