Heat-insulated, sound-proof and shock-absorbent fiber mat and preparation method

A technology for heat insulation and sound insulation and fiber mat, which is applied in the field of fiber mat production, can solve the problems of environmental pollution in the car, contain harmful substances, and pungent odor, and achieve the effects of reducing noise hazards, being convenient to use, and ensuring safe driving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

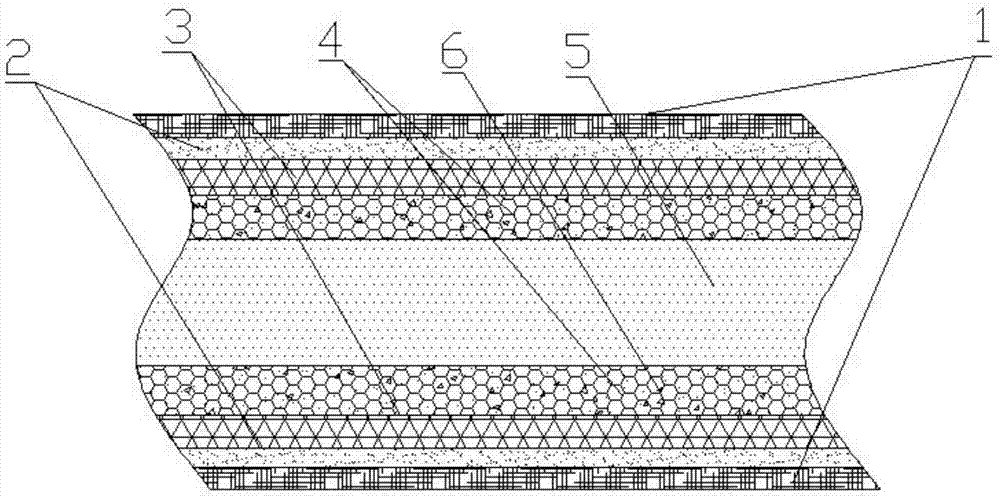

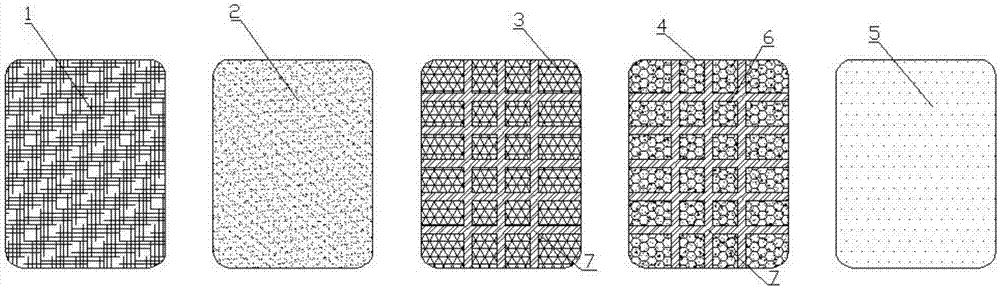

[0026] Please refer to Figure 1-6 As shown, the present invention provides a solution: a heat-insulating, sound-insulating, and shock-absorbing fiber felt and a preparation method thereof, the heat-insulating, sound-insulating, and shock-absorbing fiber felt comprising a damping sound-insulating felt 1, a PVC layer 2, a heat dissipation layer 3, and a honeycomb layer 4 , sound-absorbing cotton layer 5, filling powder 6 and shock-absorbing net 7, the outer surface of the heat-insulating, sound-insulating and shock-absorbing fiber felt is designed as a damping sound-insulating felt 1, and the inner surface of the damping sound-insulating felt 1 is pasted with a PVC layer 2, so The inner surface of the PVC layer 2 is pasted with a heat dissipation layer 3, the inner surface of the heat dissipation layer 3 is pasted with a honeycomb layer 4, and the middle of the honeycomb layer 4 is provided with a sound-absorbing cotton layer 5, and the honeycomb holes inside the honeycomb layer...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is:

[0037] The material of the filler powder 6 includes 30 parts of mica powder, 20 parts of graphite powder, 30 parts of nano-antimony-doped tin dioxide, 5 parts of nano-ferric oxide and 5 parts of nano-alumina;

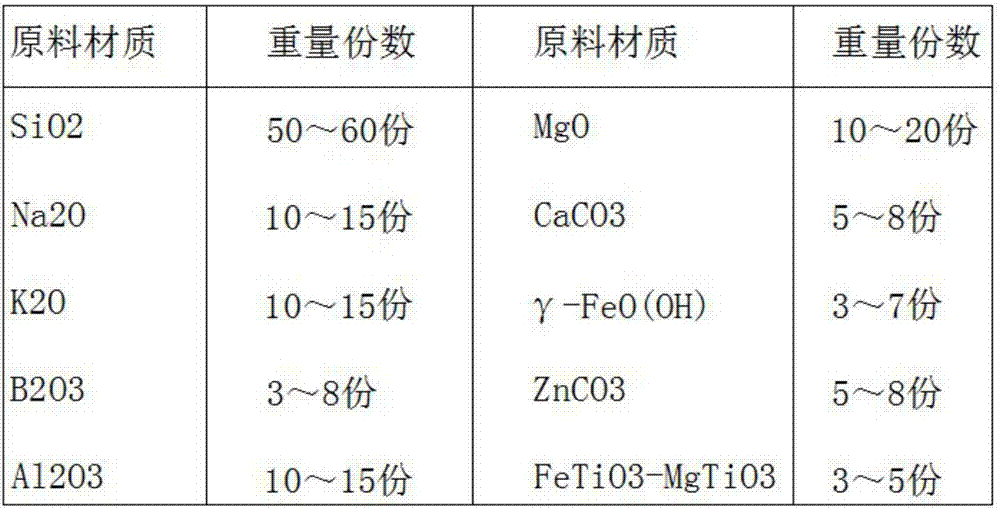

[0038] The glass fiber material in the raw material of the sound-absorbing cotton layer 5 comprises SiO 2 50 parts, Na 2 O 10 copies, K 2 O 10 parts, B 2 o 3 3 parts, Al 2 o 3 10 parts, MgO 10 parts, CaCO 3 5 parts, γ-FeO(OH) 3 parts, ZnCO 3 5 parts and FeTiO 3 -MgTiO 3 3 copies;

[0039] The plastic fiber material in the raw material of the sound-absorbing cotton layer 5 includes 50 parts of PVC resin, 5 parts of plasticizer, 3 parts of light calcium carbonate, 10 parts of paraffin, 0.5 parts of antifungal agent, 3 parts of stabilizer, nano-oxidized 3 parts of aluminum, 15 parts of butyl rubber, 2 parts of dispersant, 15 parts of maleic anhydride grafted SEBS and 15 parts of vinyl chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com