Construction technology of homogeneous photonic crystal coating

A photonic crystal and process technology, applied in the directions of printing, copying/marking methods, etc., can solve problems such as application limitations, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] At 27°C, monodisperse polystyrene colloidal particles with particle diameters of 190 nm, 215 nm, and 272 nm were dispersed in a mixed solution of diethylene glycol and ethanol to prepare a dispersion with a mass fraction of colloidal particles of 15 wt%. Among them, the mass ratio of diethylene glycol and ethanol is 1:5. Place the obtained emulsion in the liquid chamber of the spraying equipment, and spray it on the glass substrate. The spraying time is 30s. After drying, a monodispersed polystyrene particle with monodispersed polystyrene particles as a single-stack structure can be obtained. Photonic crystal thin film material.

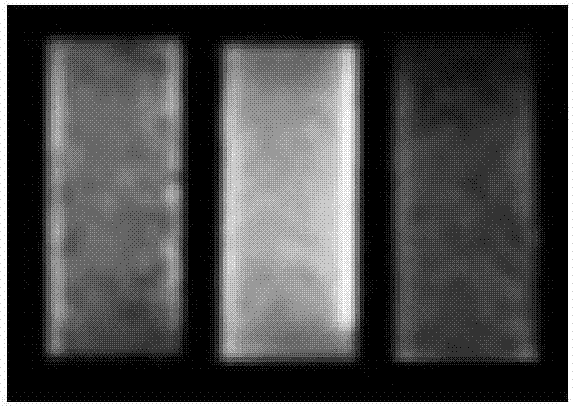

[0021] The photonic crystal film obtained by spraying is like figure 1 As shown, the prepared photonic crystal film has a uniform structure and a smooth surface without defects. Moreover, during the spraying process, by adjusting the spraying sequence of colloidal particles of different particle sizes, a photonic crystal film with a full visible...

Embodiment 2

[0023] At 35° C., monodisperse polystyrene colloidal particles with particle diameters of 180 nm, 232 nm, and 256 nm were dispersed in a mixed solution of ethylene glycol and water to prepare a dispersion with a mass fraction of colloidal particles of 20 wt%. Among them, the mass ratio of ethylene glycol and water is 1:9. First select one of the colloidal particle dispersions and place them in the liquid chamber of the spraying equipment, and spray them on the PMMA plastic film base. After drying, proceed to the next colloidal particle dispersion for spraying, where each spraying time is 45s . By controlling the spraying sequence of colloidal particles of different particle sizes, the construction of photonic crystal coatings of various colors can be realized. The coating is a photonic crystal thin film material with non-angle-dependent characteristics formed by monodisperse polystyrene particles of different particle sizes as a single stack.

Embodiment 3

[0025] Under the condition of 25° C., monodisperse polystyrene colloidal particles with a particle size of 272 nm were dispersed in a mixed solution of ethylene glycol and water to prepare a dispersion of colloidal particles with a mass fraction of 40 wt%. Among them, the mass ratio of ethylene glycol and water is 1:20. The dispersion is placed in the liquid chamber of the knife coating equipment, and then a wire rod with an etching depth of 30 μm is used to knife the paper. After the moisture is dried, the photonic crystal coating is constructed. The homogeneous photonic crystal coating is composed of a photonic crystal lattice formed by orderly stacking monodisperse polystyrene particles.

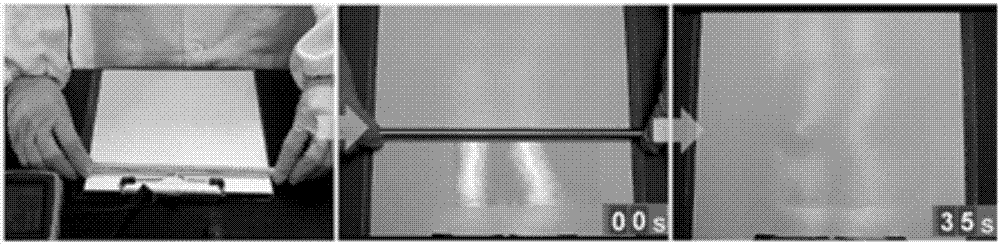

[0026] The squeegee operation process is as figure 2 As shown, it can be seen that this method has the advantages of simple equipment and fast film forming speed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com