Thermosensitive color changing material, thermosensitive color changing material microcapsule and preparation method of thermosensitive color changing material microcapsule

A technology of heat-sensitive discoloration and microcapsules, applied in the chemical industry, can solve the problems of discontinuous operation, deterioration of color and difficulty in storage, etc., and achieve the effects of reducing the impact on the human body and the environment, fast discoloration and fading, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

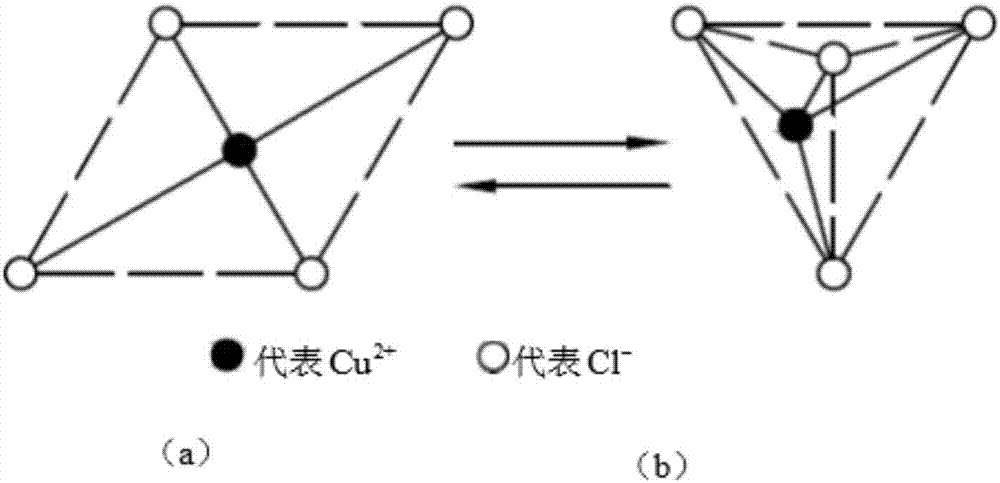

[0041] The invention provides a method for preparing microcapsules of heat-sensitive color-changing materials, which consist of a core material and a wall material wrapping the core material;

[0042] Step 1) preparing the core material, which is a thermosensitive discoloration material:

[0043] Step 1.1) Add copper salt to dehydrated alcohol, stir with glass rod to make solid dissolve completely, prepare the dehydrated ethanol solution of cupric chloride dihydrate, wherein, the mass volume ratio of copper salt and dehydrated alcohol (g / ml ) is 0.5~1:2~4; the copper salt is selected from copper chloride or copper chloride dihydrate;

[0044] Step 1.2) After adding diethylammonium chloride to isopropanol, heat and stir slightly with an electromagnetic heating stirrer to dissolve it, and prepare an isopropanol solution of diethylammonium hydrochloride, wherein diethylammonium chloride The mass volume ratio (g / ml) of ammonium to isopropanol is 1-2:6-8; the mass ratio of copper ...

Embodiment 1

[0061] 1) Add 1g of copper chloride dihydrate to 2ml of absolute alcohol, stir with a glass rod to completely dissolve the solid, and prepare an absolute ethanol solution of copper chloride dihydrate;

[0062] 2) After adding 1g of diethylammonium chloride to 6ml of isopropanol, heat and stir slightly with an electromagnetic heating stirrer to dissolve it, and prepare an isopropanol solution of diethylammonium hydrochloride;

[0063] 3) After the diethylammonium chloride is completely dissolved, add the dehydrated ethanol solution of copper chloride dihydrate dropwise with a dropper, and the solution is still placed on the heating plate for continuous heating and stirring for 30 minutes during the dropwise addition;

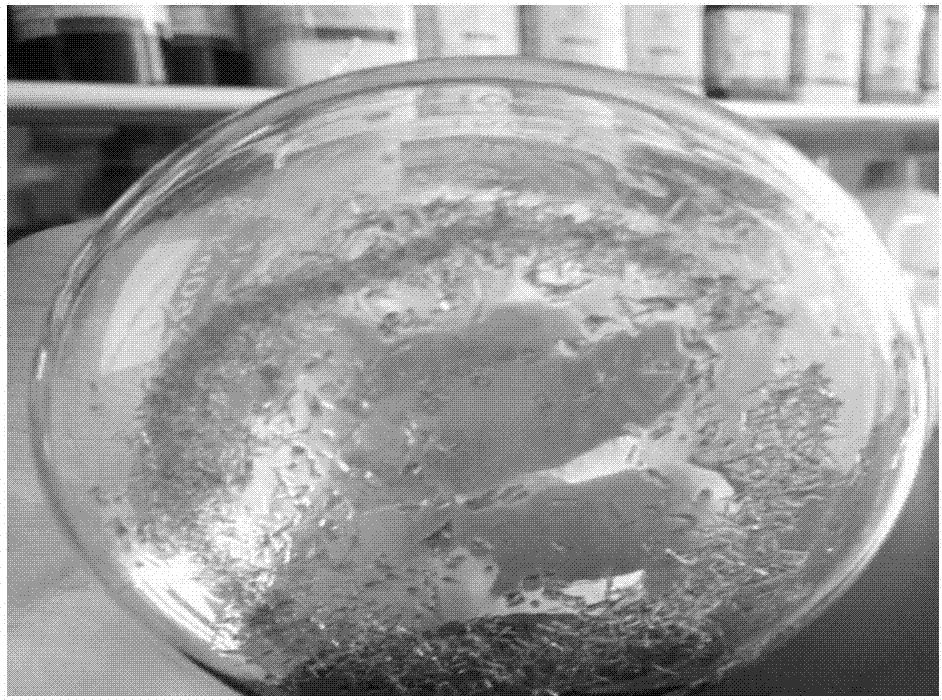

[0064] 4) Add activated 4-5 3A molecular sieves to promote the formation of crystals; after cooling with water, bright green needle-like crystals precipitate; filter quickly, wash the precipitate with a small amount of isopropanol, and store the product in a desic...

Embodiment 2

[0073] 1) Weigh 1g of copper chloride, place it in a 50mL Erlenmeyer flask, then add 2ml of water alcohol, and stir with a glass rod to completely dissolve the solid;

[0074] 2) Weigh 1g of diethylammonium chloride into a 50mL Erlenmeyer flask, add 6ml of isopropanol, heat slightly (50°C) with an electromagnetic heating stirrer and stir to dissolve;

[0075] 3) After the diethylammonium chloride is completely dissolved, add the copper chloride solution dropwise with a dropper, and the solution is still placed on the heating plate for continuous heating (50° C.) and stirred during the dropwise addition;

[0076] 4) After adding the copper chloride solution dropwise, increase the heating temperature to 60° C. to evaporate excess solvent.

[0077] 5) When the volume of the solution is evaporated and concentrated to about 4ml, place the Erlenmeyer flask on the table to cool down slightly, then place it in an ice-water bath to cool down, and observe whether crystalline solids are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com