Film plating method of metal cup

A metal cup and metal technology, applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems of increasing process steps and cost, destroying coating, low quality, etc., to save process cost , keep the beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical content, purpose of the invention and the technical effects achieved by the present invention more complete and clear, the detailed description is given below, and please refer to the disclosed drawings and drawing numbers:

[0027] First of all, the actual application technology and means of the present invention, please refer to Figure 1-Figure 5 Shown, the production schematic diagram of the coating method of metal cup of the present invention, its steps are as follows:

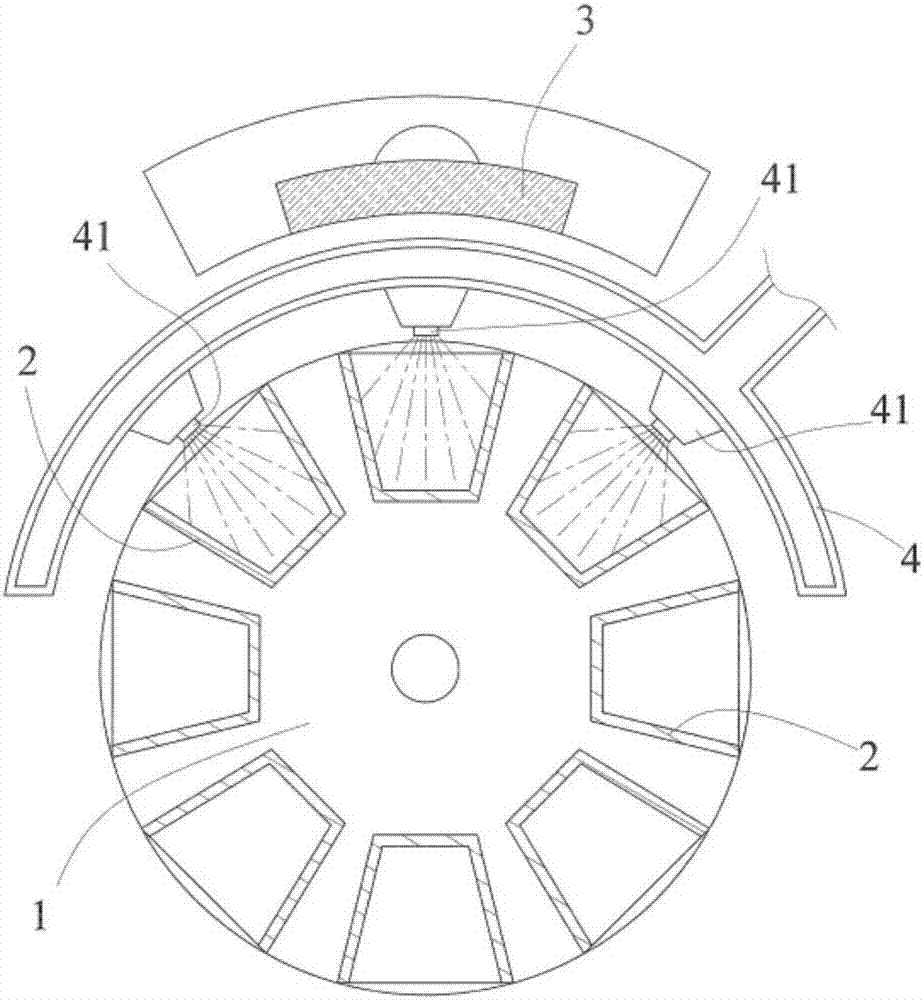

[0028] S1) In the vacuum furnace, set several metal cups 2 to be coated on the turntable 1, and the metal target 3 to be plated is fixed on one side of the turntable 1, and between the target 3 and the turntable 1 An airway fixture 4 is arranged between, and the airway fixture 4 can introduce inert gas;

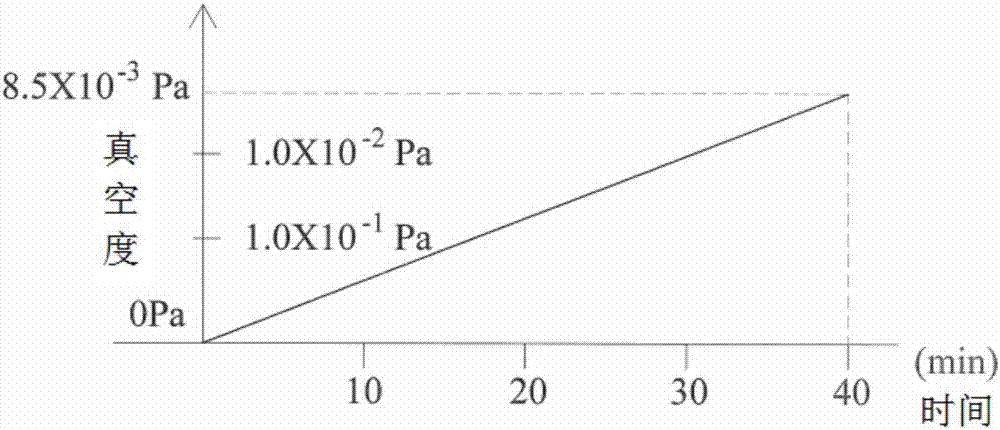

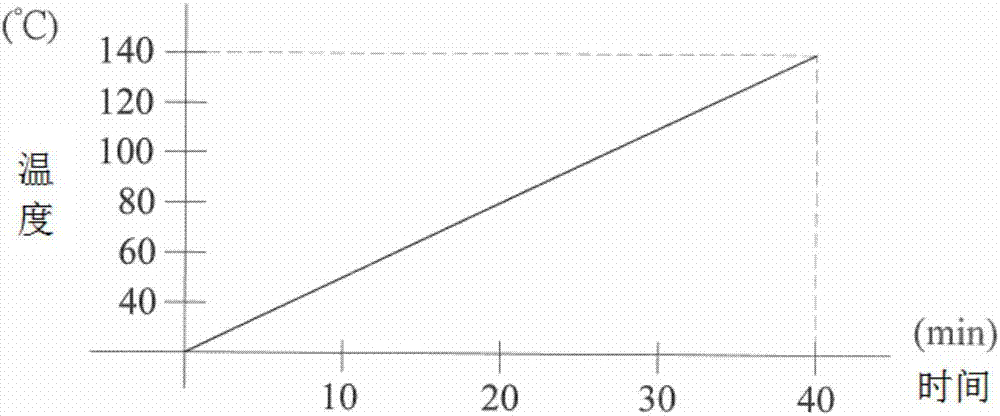

[0029] S2) Vacuum the vacuum furnace, and heat it for 40 minutes, raise the temperature to 140°C, and let the vacuum degree in the furnace reach 8.5×10 - 3 Pa sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com