Method for preparing carbon material by utilizing biomass waste materials and application of carbon material prepared by method

A biomass and carbon material technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as low adsorption efficiency, waste of resources, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

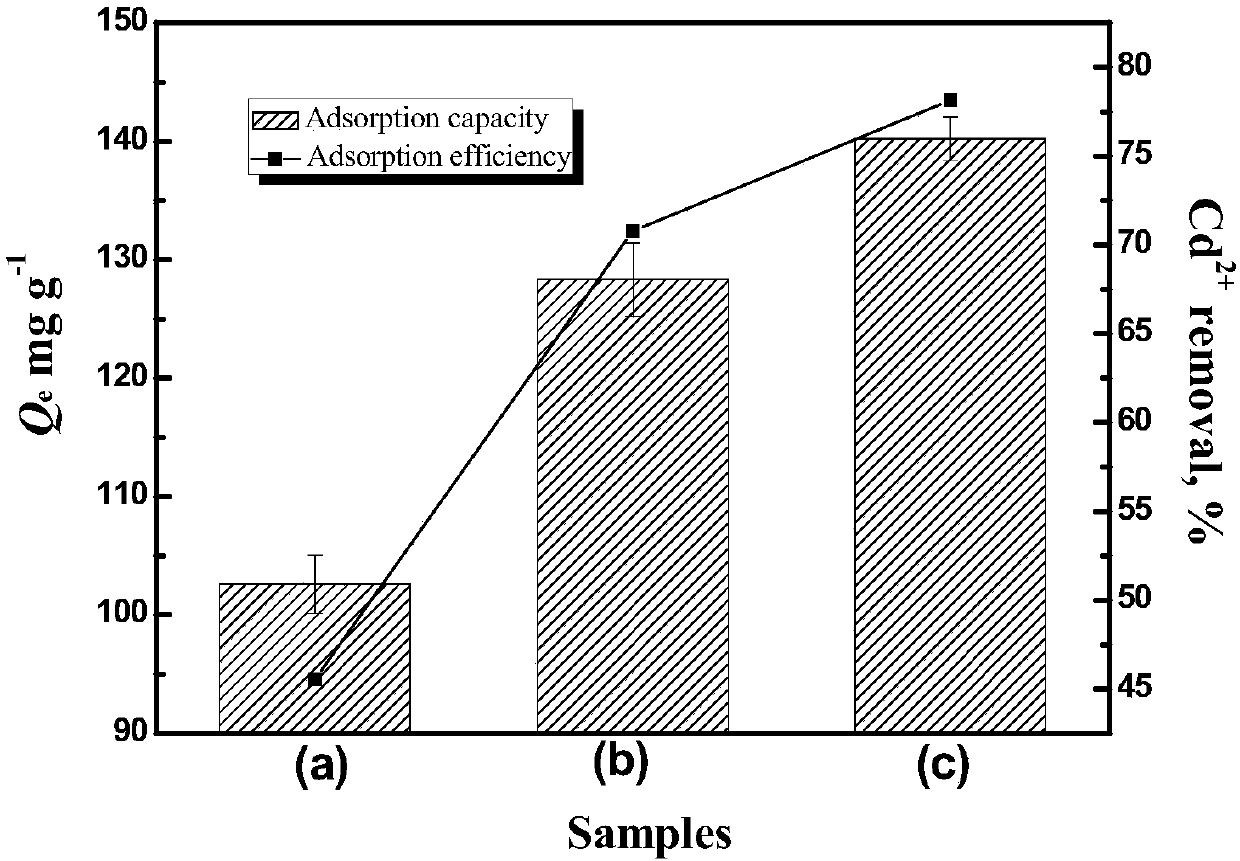

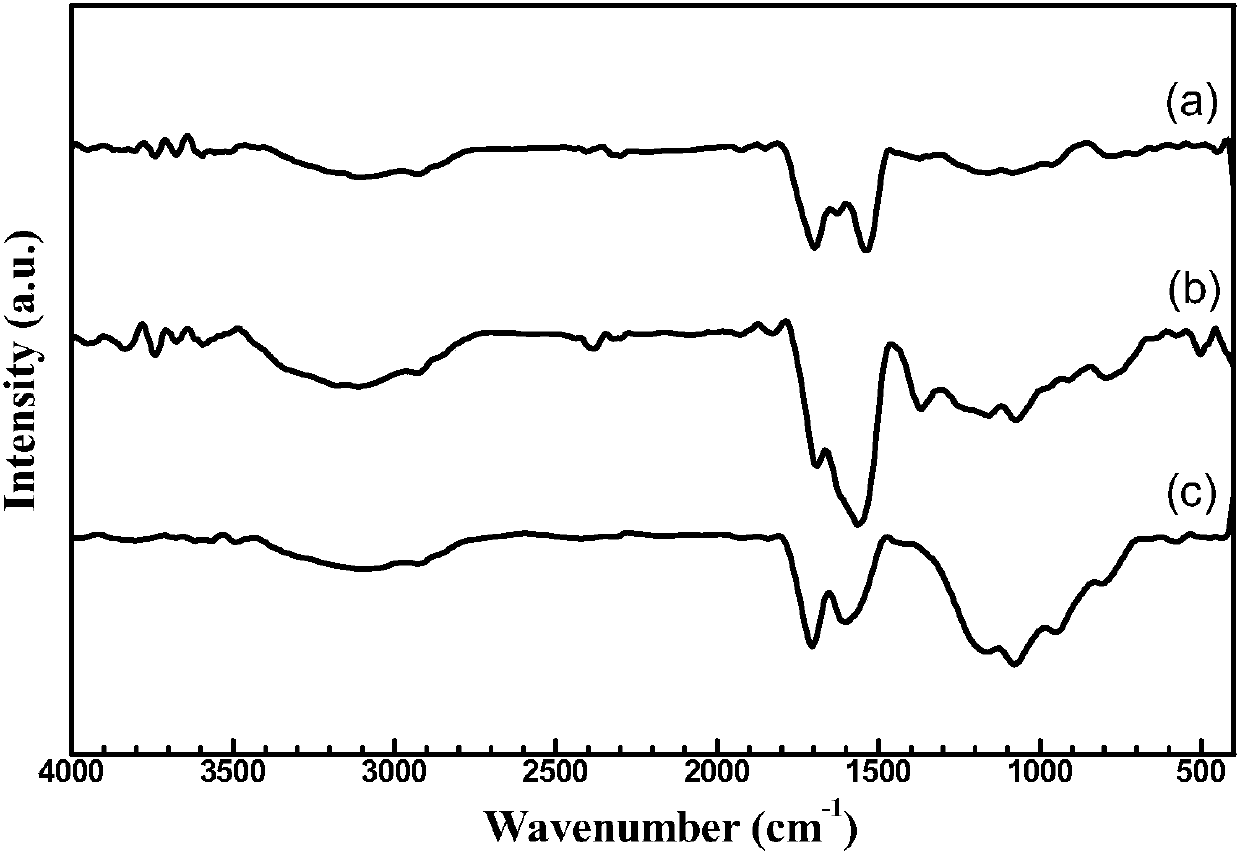

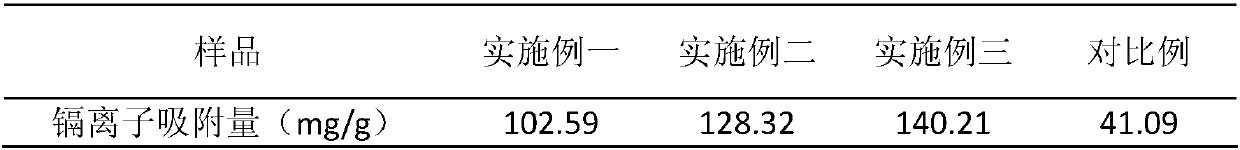

[0018] Embodiment 1: The preparation method of the functionalized carbon adsorbent material that can be used for the adsorption and repair of heavy metal polluted water environment by using biomass waste materials includes the following steps:

[0019] Dry the straw in a blast oven to constant weight and then pulverize it, mix it with 75% sulfuric acid solution at a solid-to-liquid weight-volume ratio of 1g:30ml, soak it for 1h, and place it in an improved open hydrothermal reaction kettle system. Heated to 180°C in the air in a muffle furnace, and kept for 5 hours to react to obtain a carbon precursor, filtered and washed with deionized water to neutrality, mixed with 1mol / L sodium carbonate solution, and placed in a magnetic stirring constant temperature water bath. Stir and heat at 75°C for 48 hours for hydrolysis reaction. After the reaction, wash with deionized water until neutral. After drying, you can get a functionalized carbon adsorbent material with good adsorption ch...

Embodiment 2

[0020] Embodiment 2: The preparation method of the functionalized carbon adsorbent material that can be used for the adsorption and repair of heavy metal polluted water environment by using biomass waste materials includes the following steps:

[0021] Dried the pericarp in a blast oven to constant weight and pulverized it, mixed it with 75% sulfuric acid solution at a solid-to-liquid weight-volume ratio of 1g:30ml, soaked it for 1h and placed it in an improved open hydrothermal reaction kettle system. Heated to 200°C in the air in a muffle furnace, kept for 5 hours to react to obtain a carbon precursor, filtered and washed with deionized water until neutral, mixed with 1mol / L sodium carbonate solution, placed in a magnetic stirring constant temperature water bath Stir and heat at 75°C for 24 hours for hydrolysis reaction. After the reaction, wash with deionized water until neutral, and dry to obtain a functionalized carbon adsorbent material with good adsorption characteristic...

Embodiment 3

[0022] Embodiment 3: The preparation method of the functionalized carbon adsorbent material that can be used for the adsorption and repair of heavy metal polluted water environment by using biomass waste materials includes the following steps:

[0023] Dry Miscanthus in a blast oven to constant weight and pulverize it, mix it with 85% phosphoric acid solution according to the solid-to-liquid weight volume ratio of 1g:20ml, soak it for 1h and place it in the improved open hydrothermal reaction kettle system. Heated to 220°C in the air in a muffle furnace, kept for 5 hours to react to obtain a carbon precursor, filtered and washed with deionized water until neutral, mixed with 1mol / L sodium carbonate solution, placed in a magnetic stirring constant temperature water bath Stir and heat at 75°C for 48 hours for hydrolysis reaction. After the reaction, wash with deionized water until neutral. After drying, you can get a functionalized carbon adsorbent material with good adsorption c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com