Preparation method of crayon-shaped Mn3O4 microstructure and obtained product

A technology of microstructure and polyvinylpyrrolidone, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of uneven product appearance, complicated process, and large energy consumption, and achieve uniform product appearance, strong controllability, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1.1 Add 1.919 g of manganese chloride tetrahydrate, 1.979 g of sodium acetate trihydrate, 2.153 g of PVP and 3.610 g of EDTA-2Na into a mixed solvent of 20 mL of water, 4 mL of ethanolamine and 8 mL of glycerol and stir to clarification;

[0030] 1.2 Transfer the above solution to the reactor and react at 180 °C for 16 h;

[0031] 1.3 After the reaction, the product was obtained after centrifugation and washing.

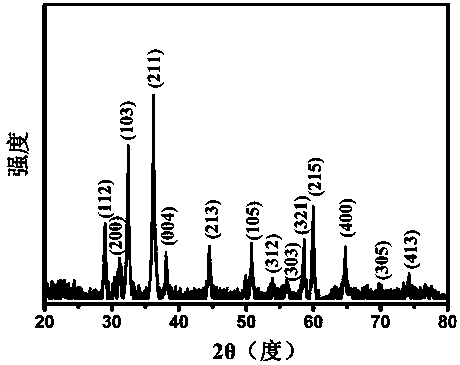

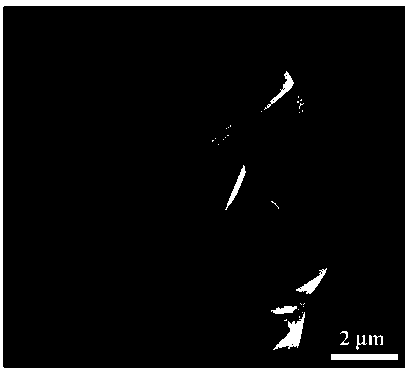

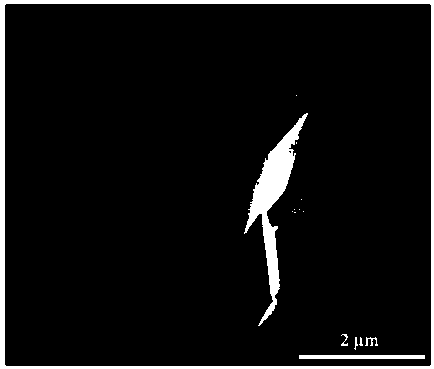

[0032] The XRD pattern of the product is as figure 1 As shown, the XRD results are consistent with the standard XRD card (24-0734), proving that the crystal phase of the obtained product is Mn 3 o 4 Mutually. The SEM picture of the product is as follows figure 2 and 3 As shown, the obtained product has a regular appearance, a flat surface, a crayon-like structure, and no other appearance, specifically: the lower part of the crayon-like structure is a hexagonal prism, the hexagonal side length of the hexagonal prism bottom is 0.75-0.90 μm, and the edge ...

Embodiment 2

[0034] 2.1 Add 1.425 g of manganese chloride tetrahydrate, 1.029 g of sodium acetate trihydrate, 2.358 g of PVP and 1.474 g of EDTA-2Na into a mixed solvent of 20 mL of water, 6 mL of ethanolamine and 5 mL of glycerol and stir to clarification;

[0035] 2.2 Transfer the above solution to the reactor and react at 160 °C for 4 h;

[0036] 2.3 After the reaction, after centrifugation and washing, a single crayon-like Mn 3 o 4 Microstructure, specifically: the lower part of the crayon-shaped structure is a hexagonal prism, the hexagonal side length of the hexagonal prism bottom is 0.09-0.15 μm, and the edge length is 0.15-0.24 μm; the upper part of the crayon-shaped structure is a hexagonal platform, the hexagonal platform The edge length is 0.10-0.17 μm, and the side length of the top hexagon is 0.05-0.08 μm.

Embodiment 3

[0038] 3.1 Add 2.239 g of manganese chloride tetrahydrate, 3.002 g of sodium acetate trihydrate, 1.319 g of PVP and 6.106 g of EDTA-2Na into a mixed solvent of 20 mL of water, 2 mL of ethanolamine and 10 mL of glycerol and stir to clarification;

[0039] 3.2 Transfer the above solution to the reactor and react at 200 °C for 26 h;

[0040] 3.3 After the reaction, after centrifugation and washing, a single crayon-like Mn 3 o 4 Microstructure, specifically: the lower part of the crayon-shaped structure is a hexagonal prism, the hexagonal side length of the hexagonal prism bottom is 2.90-3.30 μm, and the edge length is 4.64-5.28 μm; the upper part of the crayon-shaped structure is a hexagonal platform, and the hexagonal platform The edge length is 3.19-3.63 μm, and the side length of the top hexagon is 1.45-1.65 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com