Open-cell foam cement and preparation method and application thereof

An open-cell foam and cement technology, which is applied in the field of open-cell foam cement and its preparation, can solve the problems that open-cell foam cement has not been publicly reported, and achieves low water absorption and thermal conductivity, high specific modulus and compression resistance. Strength, excellent cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

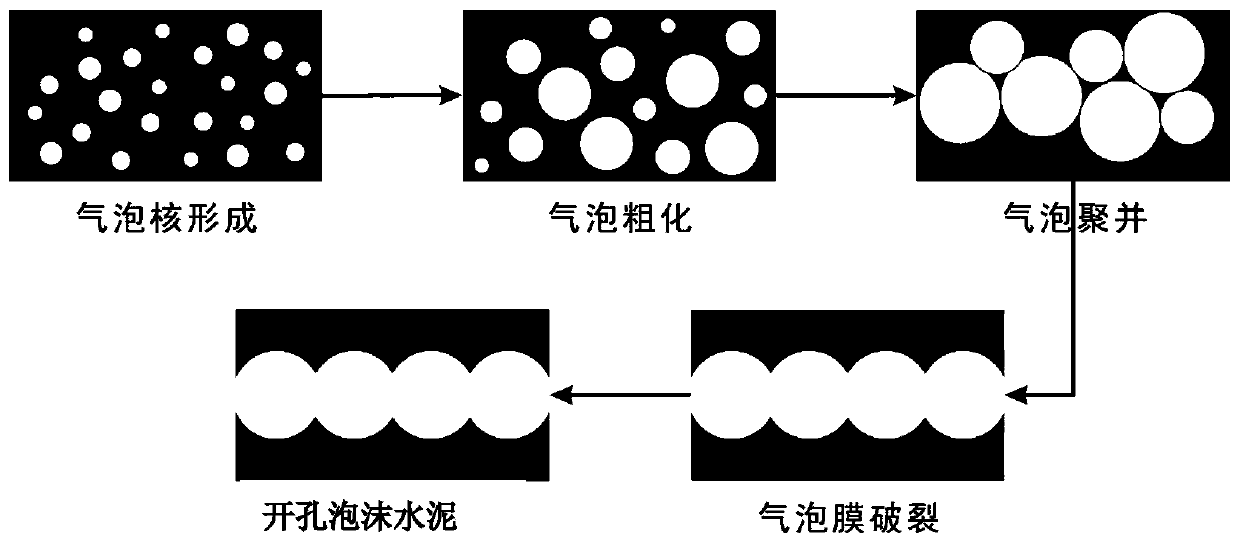

[0029] The preparation method of the open-cell foam cement includes: mixing Portland cement and sand, adding water, stirring to obtain cement slurry, adding a foaming agent to the cement slurry, feeding gas, and controlling the gas rate to 0.5-2.5 mL / 50cm 3 Min, choose a ventilation device with a cuboid structure, and place it horizontally; install a rectangular sieve plate of equal area at the gas inlet, the diameter of the selected sieve plate should be fixed, and the number of meshes should be as small as possible. In this experiment, the selected diameter is 0.3mm , The mesh number is 50 mesh sieve plates. In the process of ventilation, the parameters of the process should be set reasonably. The temperature range of the aeration process is 25°C-45°C. The pressure cannot be too high and is related to the gas velocity. Control the gas rate to 0.5-2.5mL / 50cm 3 min. After being stirred for 20-35 minutes at a rotating speed of 2000-4000 rpm, it is solidified for 12-36 hour...

Embodiment 1

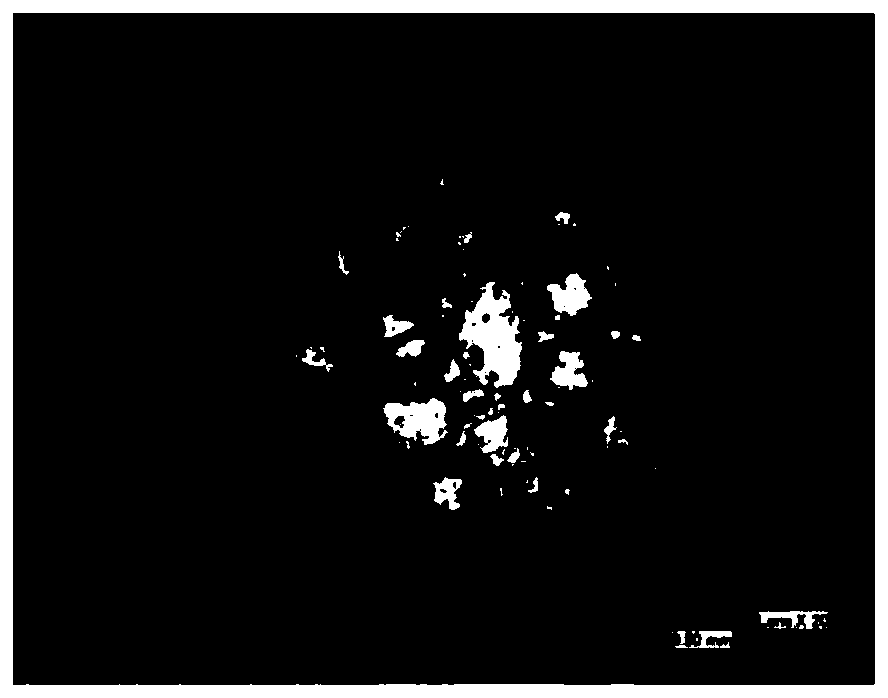

[0037] Embodiment 1: adopt formula to be the cement slurry system of 0.5% petroleum sulfonate+0.5% polyoxyethylene ether+99%, cement slurry formula is 35% portland cement, 50% sand and 14% water . Mix Portland cement and sand, add water and stir to form cement slurry, add petroleum sulfonate and polyoxyethylene ether to the cement slurry, stir, and then introduce air, control the ventilation rate to 0.5mL / 50cm 3 ·min, after stirring at 2000rmp / min for 20 minutes, the required open-cell foam cement can be obtained after curing for 24 hours. Among them, the coalescence rate of the obtained bubbles is consistent with the nucleation rate of the bubbles, which is 25mL / min. SEM of the prepared open-cell foam cement figure 2 shown. The bubble diameter is about 50nm.

[0038] After performance measurement: compressive strength up to 1.8Mpa, dry density up to 0.186g / cm 3 , The water absorption rate is 2.4%, and the thermal conductivity is 0.012W / (m.k).

Embodiment 2

[0039] Embodiment 2: adopt formula to be the cement slurry system of 0.5% sodium lauryl sulfonate+0.5% Tween+99%, the cement slurry formula is 40% Portland cement, 45% sand and 14% water. Mix Portland cement and sand, add water and stir to form a cement slurry, add sodium dodecylsulfonate and Tween to the cement slurry, stir, and then pass N 2 , control the ventilation rate to 1.0mL / 50cm 3 · min, after stirring at 2500rmp / min for 25 minutes, the open-cell foam cement was obtained through curing for 12 hours. In the preparation process, the mass fraction of the surfactant is controlled to be 0.5%, and the cement content is increased from 35% to 40%, and the open-cell foam cement can be prepared.

[0040] After performance testing: compressive strength up to 1.86Mpa, dry density up to 0.154g / cm 3 , The water absorption rate is 3.44%, and the thermal conductivity is 0.018W / (m.k).

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com