Lightweight filter material filter tank

A light-weight filter material and filter material technology, which is applied in the waste gas treatment and sewage fields, can solve the problems that the decomposition effect of the middle and lower filter materials cannot be fully exerted, increase the working frequency and intensity of backwashing, and increase the filtration resistance. Achieve the effect of small resistance, simple structure and sufficient oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

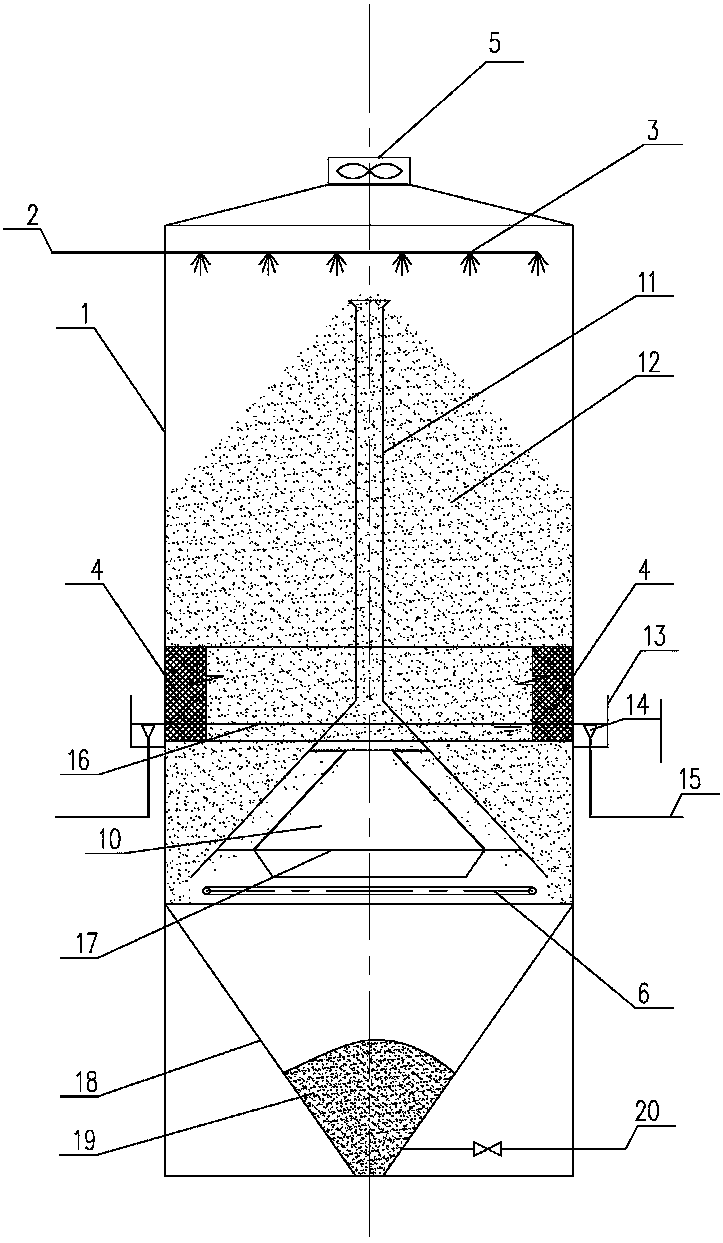

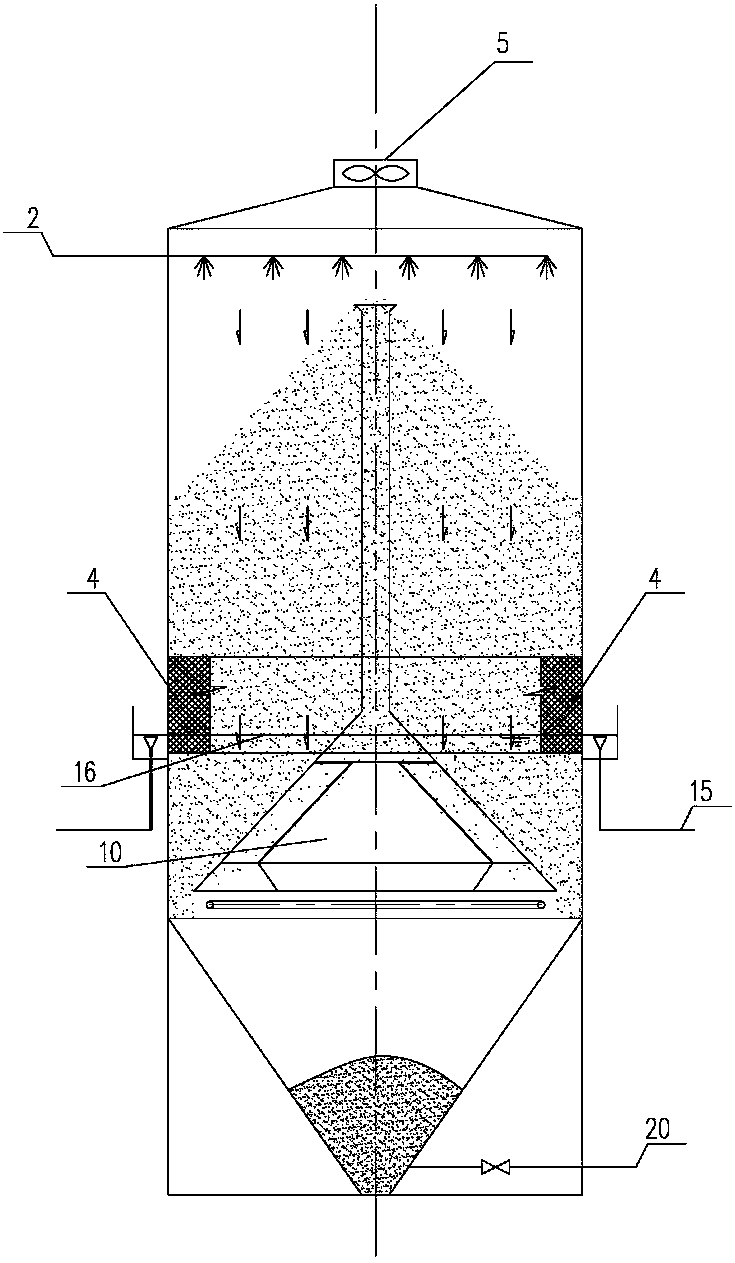

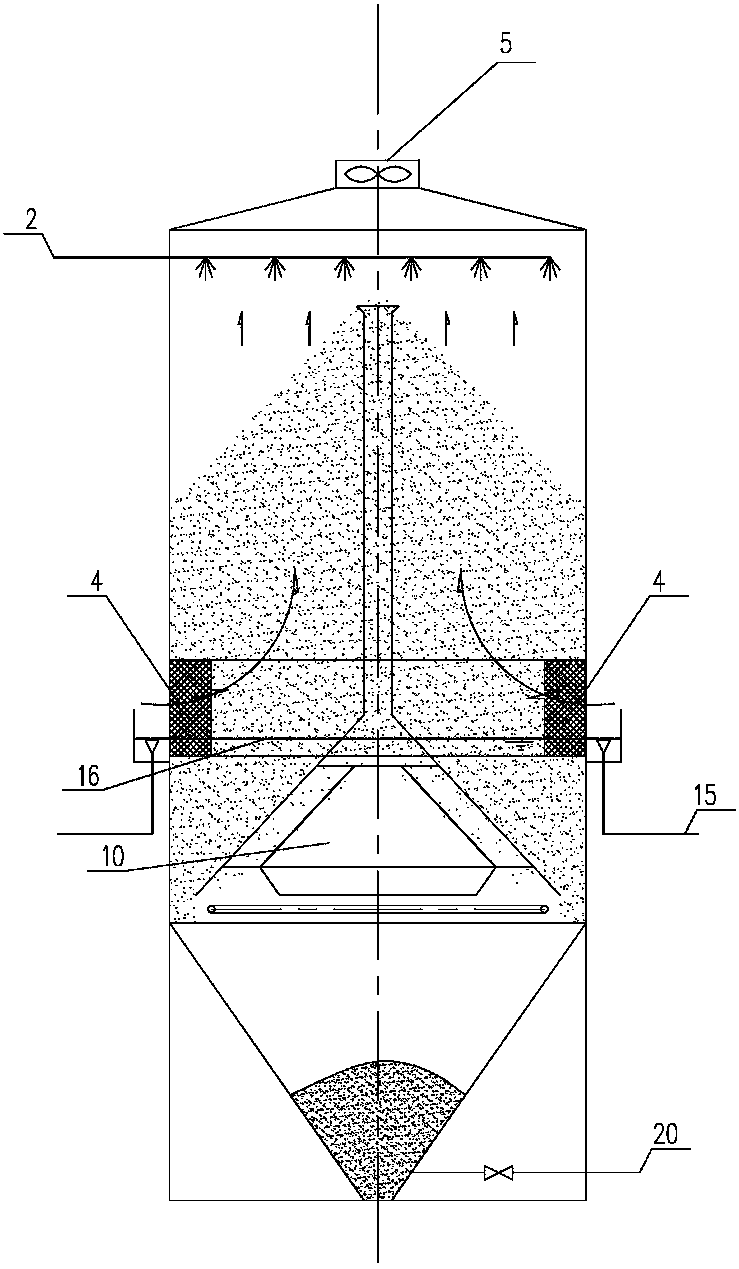

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] First fill the tank (1) with a certain amount of spheres with an apparent density of 0.1g / cm 3 Lightweight filter material (12), the pretreated raw water passes through the water inlet pipe (2) through the water distribution unit (3) under the action of the pump and gravity to form a downward flow of water, because the apparent density of the light filter material is much smaller than that of water , therefore, 1 / 10 of the lightweight filter material will be submerged in water, and 9 / 10 will float above the water level (16). pressure, and then form an air flow in the tank (1) through the air inlet (4) set in the middle of the tank (1), so that the light filter material (12) in the tank (1) maintains an oxygen-enriched state and efficiently intercepts , Degrade the pollutants in the raw water, and the water after the treatment reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com