Method and device for dewatering sludge with fly ash instead of lime

A technology for sludge dehydration and fly ash, applied in fertilization equipment, dehydration/drying/thickened sludge treatment, fertilizer mixture, etc., can solve the problems of high dehydration investment, secondary pollution, low dehydration efficiency, etc., and achieve simple process , low energy consumption, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

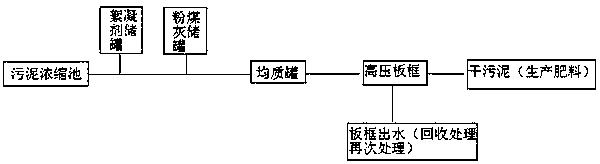

[0023] Such as figure 1 As shown, a method of fly ash instead of lime sludge dehydration is a technology of plate and frame filter press with fly ash produced in power plants instead of lime. The steps are as follows:

[0024] ① Add flocculant to the sludge generated in sewage treatment for standby, the amount of flocculant added is 0.5% of the sludge amount;

[0025] ② Dissolve the fly ash produced by the power plant in the sludge concentrate, and the amount of added fly ash is 10% of the sludge concentrate;

[0026] ③ After homogenizing the fly ash and sludge concentrate, enter the high-pressure plate frame for dehydration;

[0027] ④The extracted water is collected and carried to sewage treatment for further treatment;

[0028] ⑤ The dehydrated sludge is collected and used as fertilizer.

[0029] The moisture content of the treated sludge cake was 35.8%.

Embodiment 2

[0031] Such as figure 1 As shown, a method of fly ash instead of lime sludge dehydration is a technology of plate and frame filter press with fly ash produced in power plants instead of lime. The steps are as follows:

[0032] ① Add flocculant to the sludge produced in sewage treatment for standby, the amount of flocculant added is 1.8% of the sludge amount;

[0033] ② Dissolve the fly ash produced by the power plant in the sludge concentrate, and the amount of added fly ash is 15% of the sludge concentrate;

[0034] ③ After homogenizing the fly ash and sludge concentrate, enter the high-pressure plate frame for dehydration;

[0035] ④The extracted water is collected and carried to sewage treatment for further treatment;

[0036] ⑤ The dehydrated sludge is collected and used as fertilizer.

[0037] The moisture content of the treated sludge cake was 36.1%.

Embodiment 3

[0039] Such as figure 1 As shown, a method of fly ash instead of lime sludge dehydration is a technology of plate and frame filter press with fly ash produced in power plants instead of lime. The steps are as follows:

[0040] ① Add flocculant to the sludge generated in sewage treatment for standby, and the amount of flocculant added is 1.0% of the amount of sludge;

[0041] ② Dissolve the fly ash produced by the power plant in the sludge concentrate, and the amount of added fly ash is 13% of the sludge concentrate;

[0042] ③ After homogenizing the fly ash and sludge concentrate, enter the high-pressure plate frame for dehydration;

[0043] ④The extracted water is collected and carried to sewage treatment for further treatment;

[0044] ⑤ The dehydrated sludge is collected and used as fertilizer.

[0045] The moisture content of the treated sludge cake was 34.7%.

[0046] A dehydration device for fly ash instead of lime sludge, including a sludge thickening tank, a collec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com