A method of preparing shear thickening liquid

A liquid, polyethylene glycol technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of increasing the preparation cycle of silica shear thickening liquid, affecting the performance of shear thickening liquid, and increasing production costs. Achieve the effect of facilitating large-scale production, avoiding further separation, and reducing loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

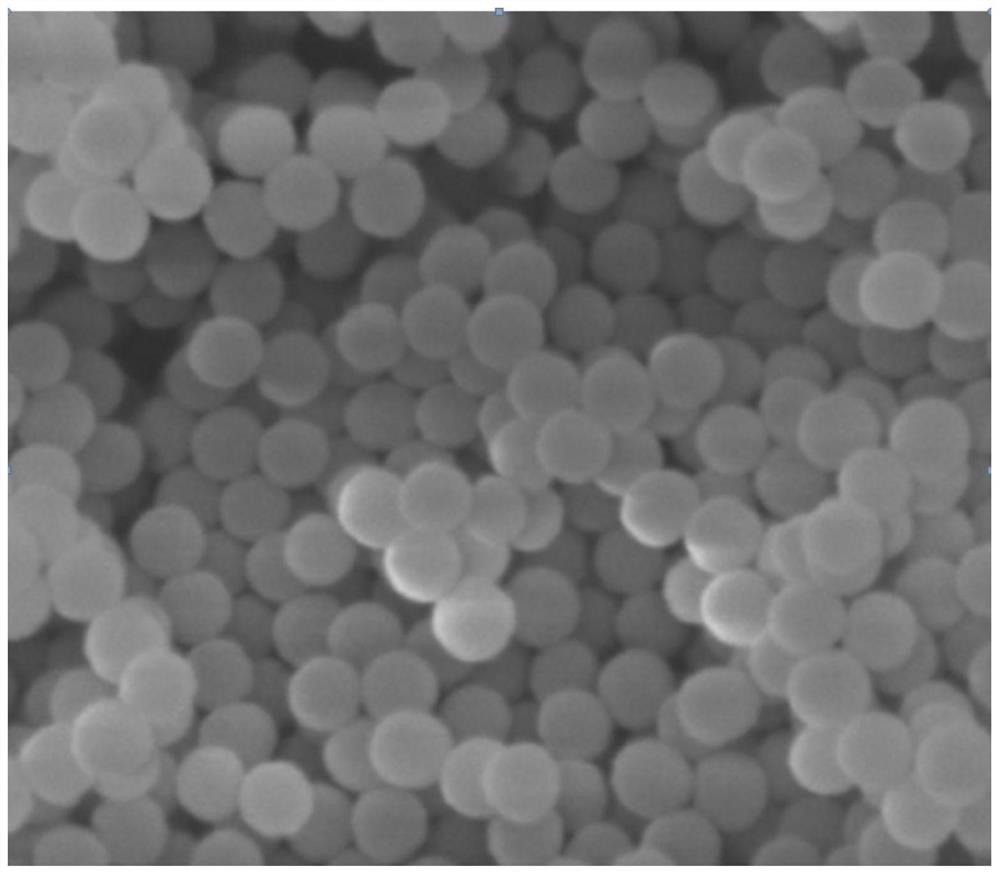

[0031] This example is a method for preparing a shear thickening liquid. The method specifically includes adding 4 kg of polyethylene glycol into an internal mixer, preheating the polyethylene glycol to 75°C, maintaining the temperature, and adding an average particle size Nano silica microspheres with a diameter of 250nm, at a speed of 40r / min, mix for the first time for 30 minutes, then add KH-570, mix for the second time for 10 minutes, take it out and seal it, cool to room temperature to obtain shear thickening liquid.

[0032] Take the prepared 200g sample, wrap an egg with the sample, and do a drop bell test. When a 500g drop bell falls vertically from a height of 1m, the egg does not break. It can be seen that the shear thickening liquid prepared in this example has good impact resistance and can effectively play a buffering role.

Embodiment 2

[0034] This example is a method for preparing a shear thickening liquid. The method specifically includes: adding 4 kg of polyethylene glycol into an internal mixer, preheating the polyethylene glycol to 85°C, maintaining the temperature, and adding the average particle size Nano-silica microspheres with a diameter of 350nm, at a speed of 60r / min, mix for the first time for 30 minutes, then add KH-560, mix for the second time for 10 minutes, take it out and seal it, cool to room temperature to obtain shear thickening liquid.

[0035] The drop weight test in Example 1 was carried out using the shear thickening liquid prepared in this example, and the eggs did not break. It can be seen that the shear thickening liquid prepared in this example has good impact resistance and can effectively play a buffering role.

Embodiment 3

[0037] This example is a method for preparing a shear thickening liquid. The method specifically includes: adding 4 kg of polyethylene glycol into an internal mixer, preheating the polyethylene glycol to 85°C, maintaining the temperature, and adding the average particle size Nano silica microspheres with a diameter of 450nm, at a speed of 50r / min, mix for 35 minutes for the first time, then add KH-560, mix for 8 minutes for the second time, take it out and seal it, cool to room temperature to obtain shear thickening liquid.

[0038] The drop weight test in Example 1 was carried out using the shear thickening liquid prepared in this example, and the eggs did not break. The shear thickening liquid prepared in this embodiment has good impact resistance and can effectively play a buffering role.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com