Method of microorganism wax removing and preventing of high-temperature and high-salinity high-wax-bearing oil well

A high-temperature, high-salt, microbial technology, used in cleaning appliances, earth-moving drilling, wellbore/well components, etc., can solve problems such as large differences in microbial metabolic activity and quantity, difficult to form competitive dominant bacteria, and discounted application effects. , to achieve the effect of low cost, wide application range and long effect period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Oil well A in an oil field 3 , reservoir temperature 75℃, permeability 750×10 -3 μm 2 , the wax content of the crude oil is 23.2%, the thickness of the oil layer is 3.4m, the salinity of the formation water is 89563mg / L, and the daily fluid of the well is 80m before the test 3 , the daily oil production is 3.5t, the water content is 95.6%, and the method of the present invention is used in the oil well A 3 The implementation of the field test, the specific implementation steps are as follows:

[0041] (1) Screening of oil wells

[0042] Well A 3 Reservoir temperature≤95℃, permeability≥50×10 -3 μm 2 , the salinity of formation water is less than or equal to 150000mg / L, and the wax content of crude oil is less than or equal to 30%, which meet the screening standards of the present invention.

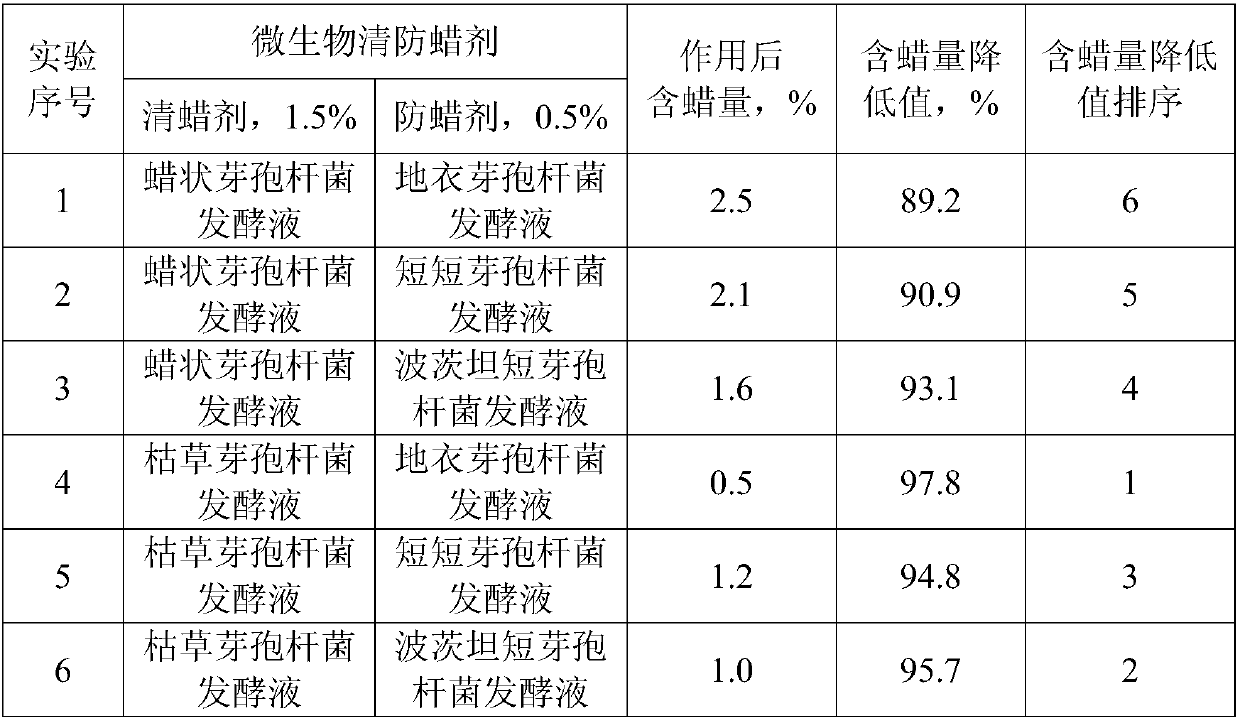

[0043] (2) Screening of microbial wax remover and inhibitor

[0044] The screening method of microbial wax remover and inhibitor is as follows: ① Field sampling of test oil ...

Embodiment 2

[0057] Oil well B in an oil field 12 , reservoir temperature 87℃, permeability 980×10 -3 μm 2 , the wax content of the crude oil is 26.8%, the thickness of the oil layer is 8.5m, the salinity of the formation water is 125600mg / L, and the daily liquid of the well before the test is 95m 3 , the daily oil production is 4.3t, the water content is 95.5%, and the method of the present invention is used in the oil well B 12 The implementation of the field test, the specific implementation steps are as follows:

[0058] (1) Screening of oil wells

[0059] Well B 12 Reservoir temperature≤95℃, permeability≥50×10 -3 μm 2 , the salinity of formation water is less than or equal to 150000mg / L, and the wax content of crude oil is less than or equal to 30%, which meet the screening standards of the present invention.

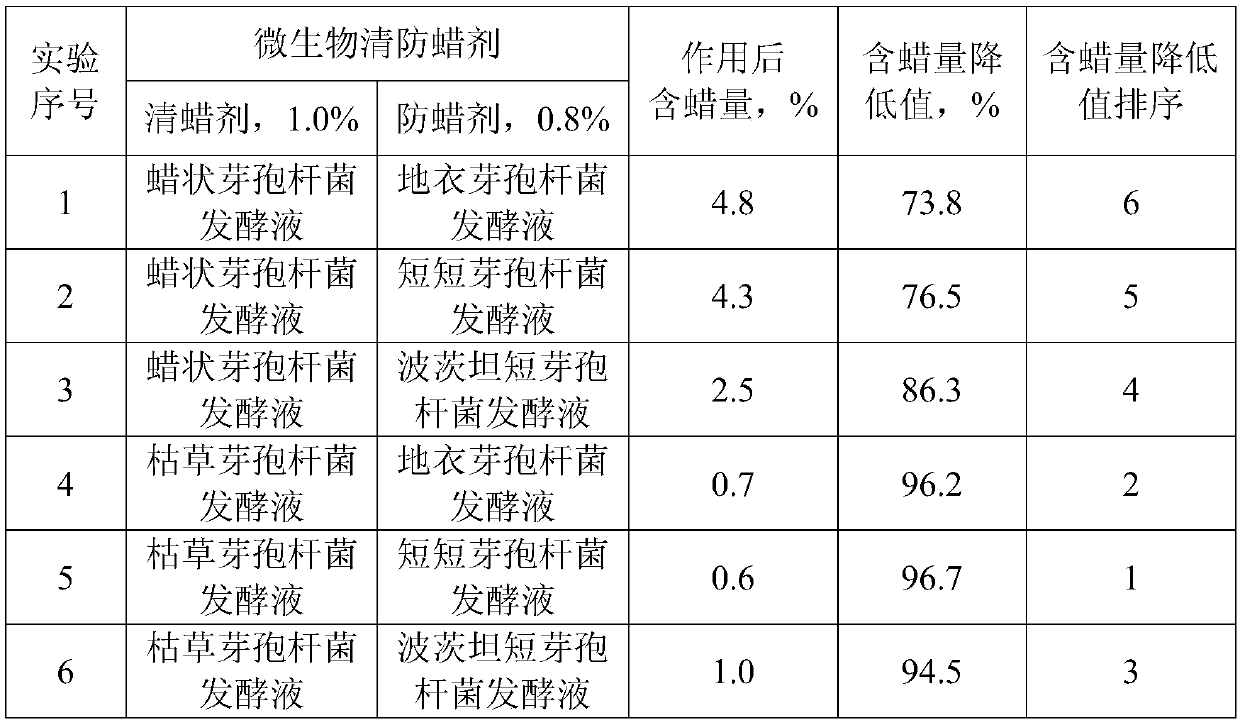

[0060] (2) Screening of microbial wax remover and inhibitor

[0061] The screening method for microbial wax remover and inhibitor is as follows: ① Field sampling of tes...

Embodiment 3

[0074] Oil well F in an oil field 21 , reservoir temperature 82℃, permeability 630×10 -3 μm 2 , the wax content of the crude oil is 18.3%, the thickness of the oil layer is 6.3m, the salinity of the formation water is 114560mg / L, and the daily fluid of the well before the test is 63m 3 , the daily oil production is 4.0t, the water content is 93.7%, and the method of the present invention is used in the oil well F 21 The implementation of the field test, the specific implementation steps are as follows:

[0075] (1) Screening of oil wells

[0076] Well F 21 Reservoir temperature≤95℃, permeability≥50×10 -3 μm 2 , the salinity of formation water is less than or equal to 150000mg / L, and the wax content of crude oil is less than or equal to 30%, which meet the screening standards of the present invention.

[0077] (2) Screening of microbial wax remover and inhibitor

[0078] The screening method of microbial wax remover and inhibitor is as follows: ① Field sampling of test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com