All working condition standard emission control method for thermal power unit denitration system

A technology for thermal power unit and emission control, applied in adaptive control, general control system, control/regulation system, etc., can solve the problems of denitration system operation performance impact, poor automatic input rate and input effect, and large control lag, etc. Achieve the effect of improving closed-loop stability and anti-disturbance ability, improving automation level, and accurately controlling the amount of ammonia injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

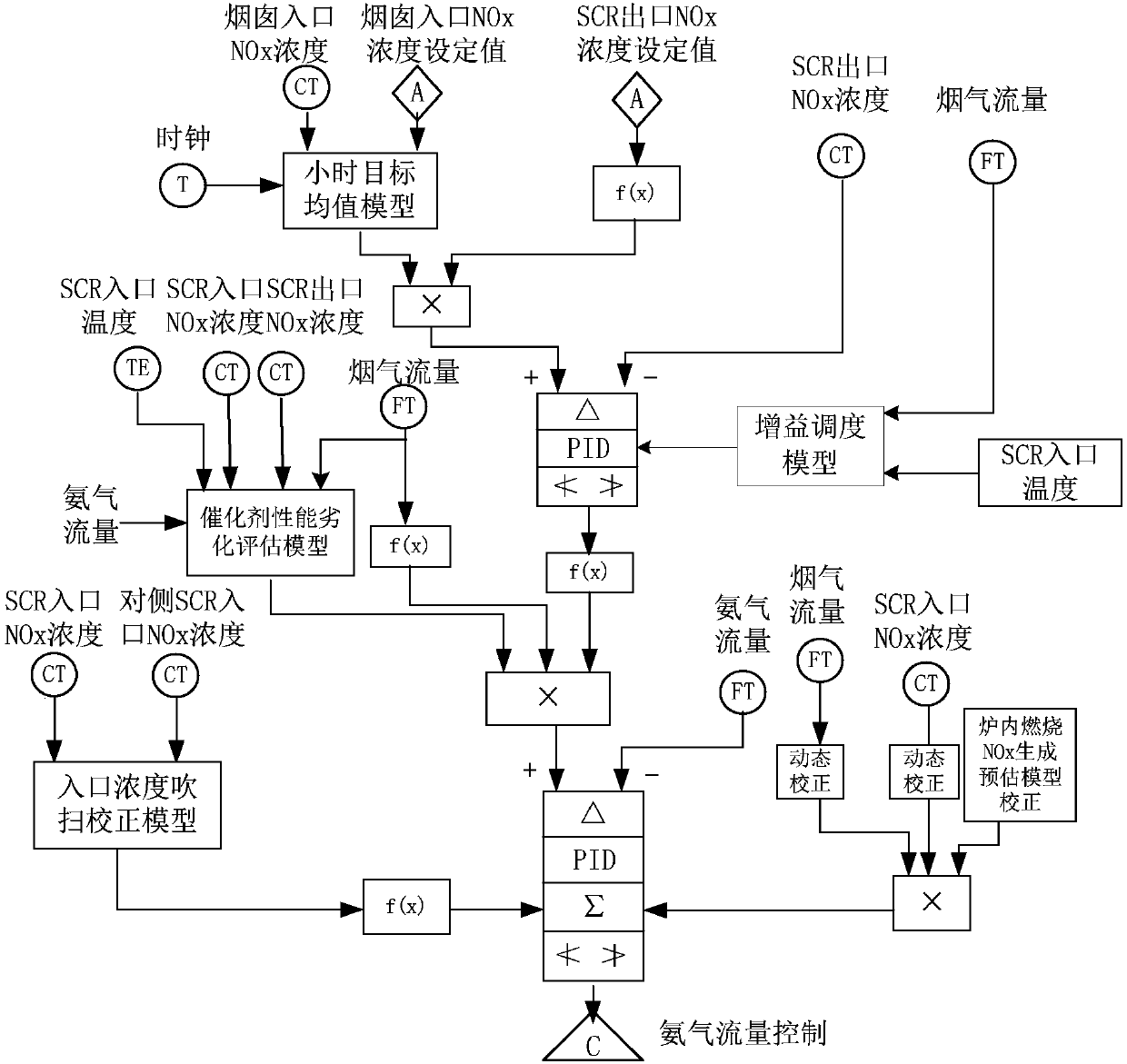

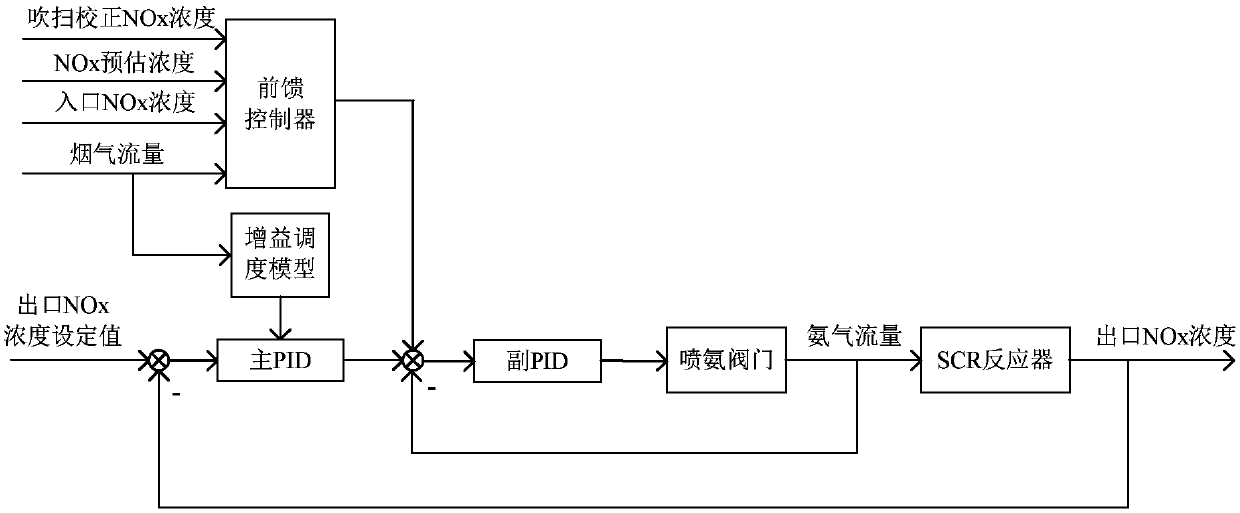

[0029] figure 1 It is the overall scheme diagram of the SCR denitrification automatic control system of the present invention. In the figure, there is mainly an hourly target average model. According to the measured value and set value of the NOx concentration at the chimney inlet and the time measured by the clock as the basis, the weighted average of the NOx concentration deviation at the chimney inlet per hour is obtained, combined with the NOx concentration at the outlet of the denitrification reactor. The set point can be more accurate and representatively reflect the NOx concentration level at the chimney inlet. Catalyst performance degradation evaluation model, the catalyst activity b is obtained according to the measured values of the inlet and outlet NOx concentrations, flue gas flow and ammonia flow of the denitrification reactor, so as to reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com