Cefuroxime axetil pharmaceutical composition prepared by direct compression method

A technology for furoctate axetil tablets and cephalosporins, which is applied in the field of fast-dissolving cefuroxime axetil pharmaceutical compositions, can solve the problems of large gap in bulk density, poor material fluidity, increased risk and workload, etc., and achieves stable properties of excipients. , Solve the effect of poor material fluidity and avoid poor compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

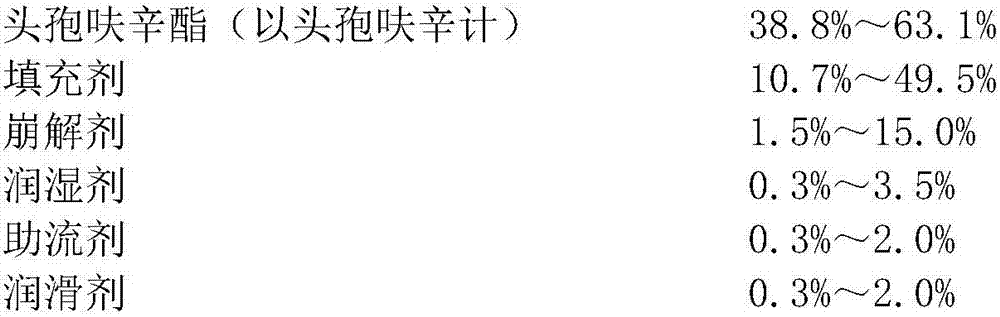

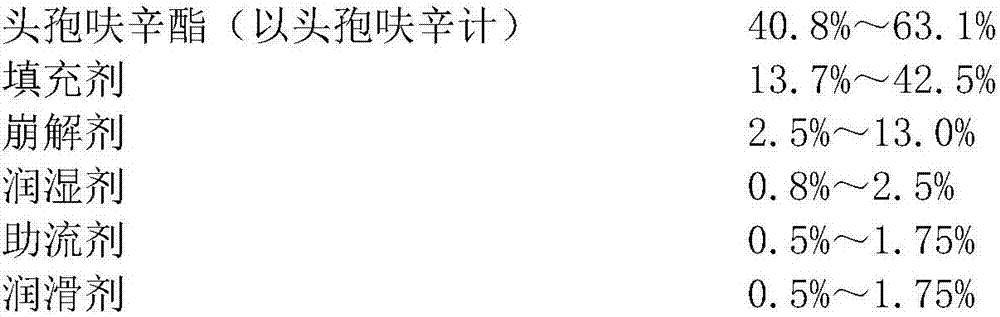

Method used

Image

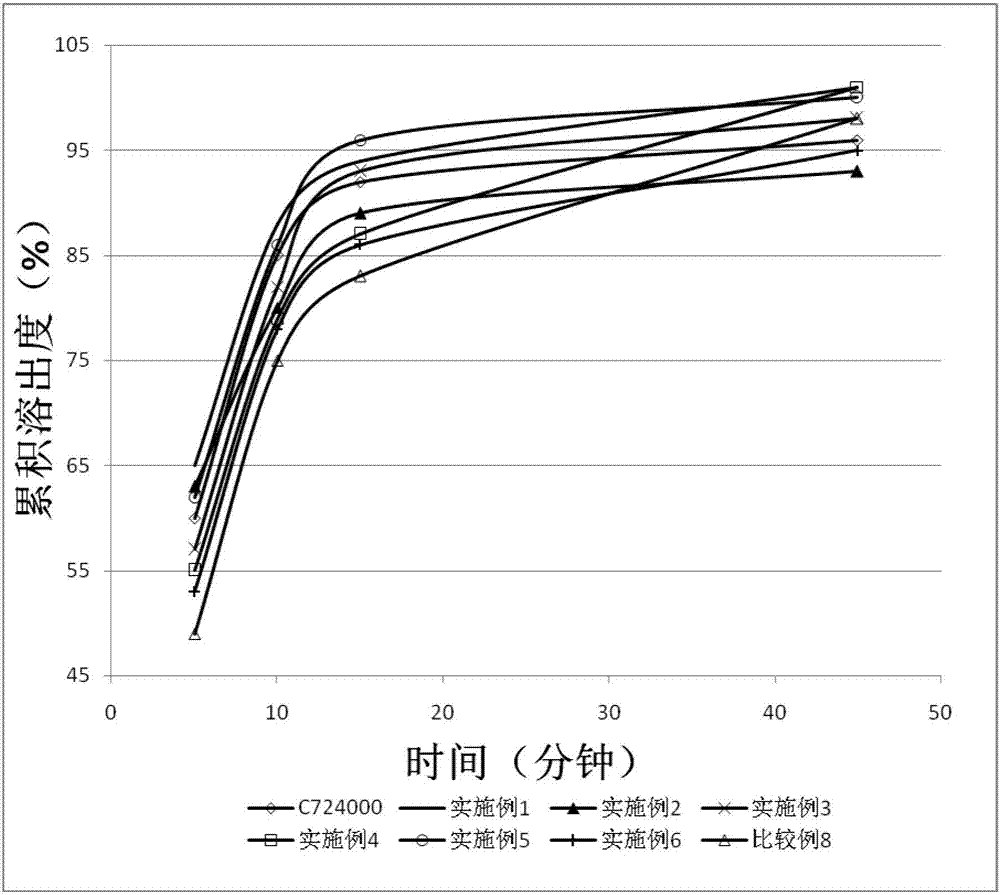

Examples

Embodiment 1

[0041] Embodiment 1 (1000 pieces)

[0042]

[0043] The preparation method is as follows:

[0044] (1) Each raw and auxiliary material in the prescription is passed through a 60-mesh sieve respectively, and set aside;

[0045] (2) Weigh the raw and auxiliary materials according to the composition of the prescription;

[0046] (3) Place each component in the prescription in a three-dimensional oscillating mixer, set the rotation speed at 10-15 rpm, and mix for 15 minutes to obtain the intermediate;

[0047] (4) Detect the content of intermediates, calculate the weight of the tablet, and then compress the tablet, the main pressure is 20KN ~ 30KN;

[0048] (5) Coating, the weight gain of coating is 2-4%;

[0049] (6) Packaging.

Embodiment 2

[0050] Embodiment 2 (1000 pieces)

[0051]

[0052] The preparation method is as follows:

[0053] (1) Each raw and auxiliary material in the prescription is passed through a 60-mesh sieve respectively, and set aside;

[0054] (2) Weigh the raw and auxiliary materials according to the composition of the prescription;

[0055] (3) Place each component in the prescription in a three-dimensional oscillating mixer, set the rotation speed at 10-15 rpm, and mix for 15 minutes to obtain the intermediate;

[0056] (4) Detect the content of intermediates, calculate the weight of the tablet and press it, the main pressure is 20KN ~ 30KN;

[0057] (5) Coating, the weight gain of coating is 2-4%;

[0058] (6) Packaging.

Embodiment 3

[0059] Embodiment 3 (1000 pieces)

[0060]

[0061]

[0062] The preparation method is as follows:

[0063] (1) Each raw and auxiliary material in the prescription is passed through a 60-mesh sieve respectively, and set aside;

[0064] (2) Weigh the raw and auxiliary materials according to the composition of the prescription;

[0065] (3) Place each component in the prescription in a three-dimensional oscillating mixer, set the rotation speed at 10-15 rpm, and mix for 15 minutes to obtain the intermediate;

[0066] (4) Detect the content of intermediates, calculate the weight of the tablet and press it, the main pressure is 20KN ~ 30KN;

[0067] (5) Coating, the weight gain of coating is 2-4%;

[0068] (6) Packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com