Expendable pattern graphite chilling gravity casting technology for railway cast steel wheels

A lost foam casting and gravity casting technology, applied in manufacturing tools, casting equipment, molds, etc., can solve the problems of waste sand discharge, low recycling rate of sodium silicate sand, affecting the surrounding ecological environment, etc., and reduce consumption. And the discharge of waste sand, the effect of good chilling effect and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

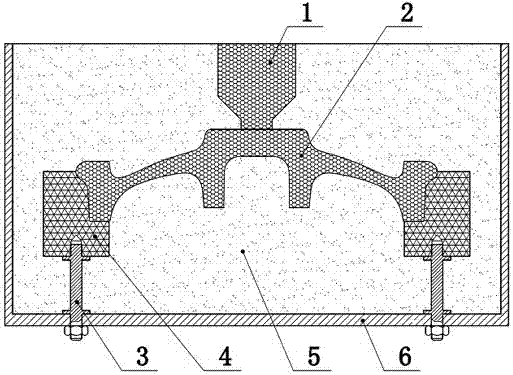

[0015] like figure 1 As shown, a lost foam graphite chilled gravity casting process for railway cast steel wheels combines the advantages of lost foam casting technology and graphite chilled process, and the graphite ring 4 that is ready to be formed is fixed on the lost foam casting sand by bolts 3 In the box 6, the molded pouring riser foam pattern 1 and the wheel foam pattern 2 are bonded and placed in the graphite ring 4, and dry sand 5 is filled into the lost foam casting sand box 6. Under a certain negative pressure state, the wheel is poured out with a bottom casting ladle.

[0016] In this example, in figure 1 Among them, the thread roots at both ends of the bolt 3 are provided with positioning bosses, and the two ends of the bolt 3 are respectively connected with the graphite ring 4 and the lost foam casting sand box 6, and are supported and positioned by the positioning bosses at both ends to ensure that the graphite ring 4 The height from the bottom of the lost fo...

specific Embodiment 2

[0017] like figure 1 As shown, this embodiment is further described on the basis of specific embodiment 1. The graphite ring 4 is located on the outer side of the corresponding wheel rim, and the formed pouring riser foam pattern 1 is located at the center above the wheel hub. The formed wheel Foam pattern 2 hub hole is designed as a concave shape to reduce the machining allowance of the axle hole of the wheel blank.

specific Embodiment 3

[0018] This example further explains the pouring process on the basis of specific example 1. Bottom pouring ladle is used for pouring, molten steel is injected through the foam pattern 1 of the pouring riser, and the foam pattern 1 of the pouring riser and the foam pattern 2 of the wheel meet the molten steel. After gasification, the gas is sucked away by the vacuum pump connected to the lost foam casting sand box 6, and the molten steel replaces the space of the foam pattern. The wheel body is fed, and the rim of the wheel is rapidly solidified under the action of graphite ring chilling to form a dense structure. After the end, the sand box is depressurized, the box is turned over to shake off the sand, and the wheel is taken out. The waste sand is recycled online after magnetic separation, dust removal, and cooling. After the graphite ring 4 is forced to cool, it is also recycled online.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com