Foam concrete formula and preparation method and application thereof

A foamed concrete and formula technology, applied in the field of concrete, can solve the problems of inability to flow away in time and low strength of concrete structure, and achieve the effect that the bearing capacity is not easy to break and the bearing capacity is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

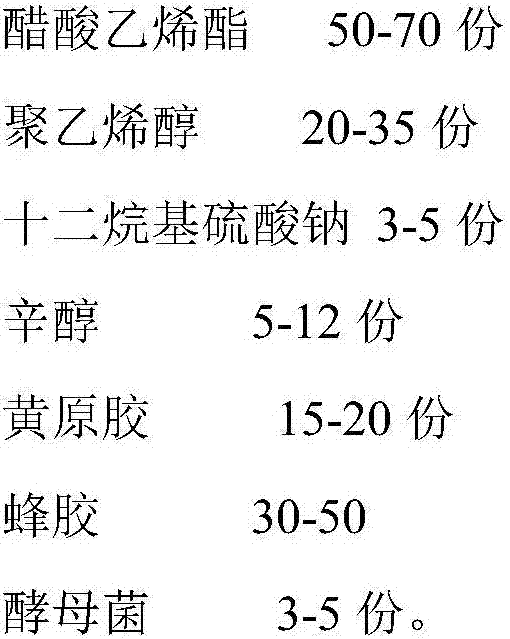

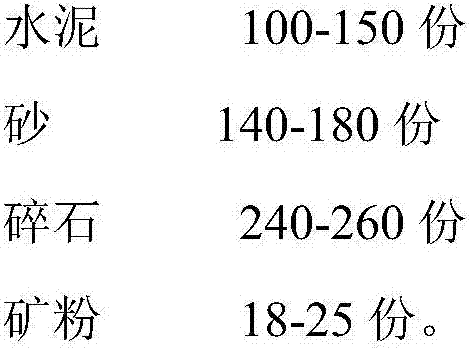

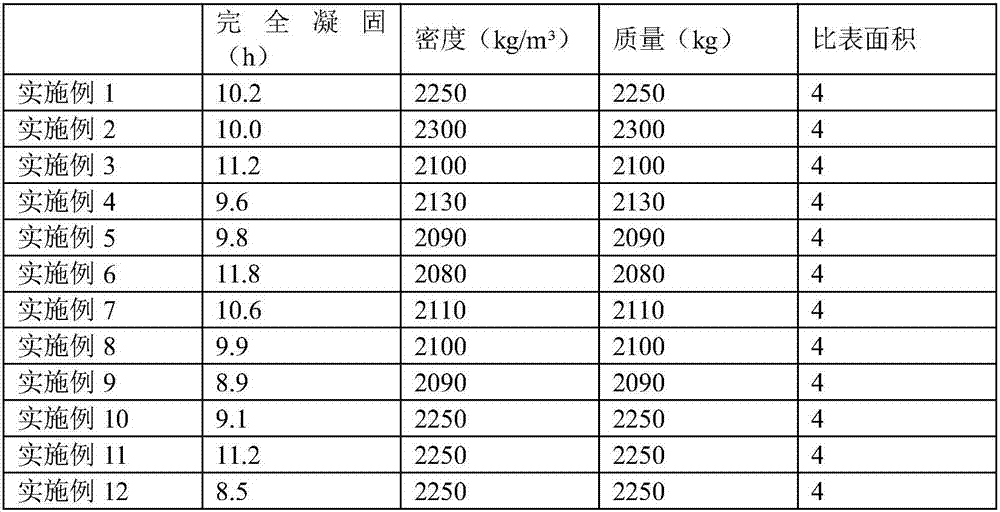

Embodiment 1

[0036] Take a clean container, weigh 100 parts of cement, 140 parts of sand, 240 parts of crushed stone, and 18 parts of mineral powder into it, and stir; then weigh 25 parts of vinyl acetate, 10 parts of polyvinyl alcohol, 1.5 parts of ten Sodium dialkyl sulfate, 2.5 parts of octanol, 7.5 parts of xanthan gum, 15 parts of propolis, 1.5 parts of yeast and 1.5 parts of sodium bicarbonate, propolis can be artificial propolis, imported into another clean container, and stirred to make it internal Uniform bubbles; weigh 37.5 parts of diluent, diluent is water, mix it with vinyl acetate, polyvinyl alcohol, sodium lauryl sulfate, octanol, xanthan gum, propolis, yeast and sodium bicarbonate After stirring, pour it into cement, sand, gravel, ore powder and continue stirring until pouring.

Embodiment 2

[0038] Take a clean container, weigh 150 parts of cement, 180 parts of sand, 260 parts of crushed stone, and 25 parts of mineral powder, add it into it, and stir it; then weigh 25 parts of vinyl acetate, 10 parts of polyvinyl alcohol, 1.5 parts of twelve Sodium alkyl sulfate, 2.5 parts of octanol, 7.5 parts of xanthan gum, 15 parts of propolis, 1.5 parts of yeast and 1.5 parts of sodium bicarbonate, propolis can be artificial propolis, introduced into another clean container, and stirred to make the inside uniform Bubbles; Weigh 37.5 parts of diluent, diluent adopts clear water, mix it with vinyl acetate, polyvinyl alcohol, sodium lauryl sulfate, octanol, xanthan gum, propolis, yeast and sodium bicarbonate Then pour it into cement, sand, gravel, ore powder and keep stirring until pouring.

Embodiment 3

[0040]Take a clean container, weigh 135 parts of cement, 160 parts of sand, 250 parts of crushed stone, and 22 parts of mineral powder, add it into it, and stir it; then weigh 25 parts of vinyl acetate, 10 parts of polyvinyl alcohol, 1.5 parts of twelve Sodium alkyl sulfate, 2.5 parts of octanol, 7.5 parts of xanthan gum, 15 parts of propolis, 1.5 parts of yeast and 1.5 parts of sodium bicarbonate, propolis can be artificial propolis, introduced into another clean container, and stirred to make the inside uniform Bubbles; Weigh 37.5 parts of diluent, diluent adopts clear water, mix it with vinyl acetate, polyvinyl alcohol, sodium lauryl sulfate, octanol, xanthan gum, propolis, yeast and sodium bicarbonate Then pour it into cement, sand, gravel, ore powder and keep stirring until pouring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com