Static breaking agent and preparation method thereof

A technology of static breaking agent and reinforcing agent, which is applied in the field of static breaking agent and its preparation, which can solve the problems of personal safety and injury, and achieve the effects of reducing hydration speed, low cost and strong expansion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

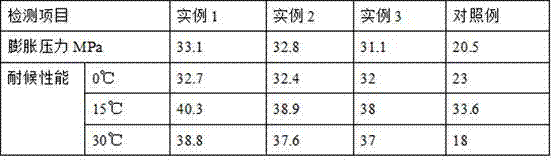

Examples

example 1

[0026] Take 900g of industrial heavy calcium powder and 50g of iron oxide, mix them evenly, add 30g of deionized water, mix them evenly, mold them into shape, put them in a drying oven, dry them at 105°C to constant weight, and then transfer them to a muffle furnace , at a heating rate of 20°C / min to 1400°C, heat-preserved and calcined for 1 hour, cooled to room temperature, put it into a pulverizer and pulverized it, passed through a 40-mesh sieve to obtain burnt lime clinker, took 60g burnt lime clinker, and 8g condensed Hardener, 10g coagulation enhancer, 2g booster, put into a ball mill and ball mill until the specific surface area is 180m 2 / kg, then add 3g retarder, 1g water reducer, 1g heat conduction agent, continue ball milling for 30min, pass through 60 mesh sieve, and package static breaker.

example 2

[0028] Take 920g of industrial heavy calcium powder and 80g of iron oxide, mix them evenly, add 40g of deionized water, mix them evenly, mold them into shape, put them in a drying oven, dry them at 108°C to constant weight, and then transfer them to a muffle furnace , at a heating rate of 30°C / min to 1420°C, heat-preserved and calcined for 1 hour, cooled to room temperature, put into a pulverizer and pulverized, passed through a 40-mesh sieve to obtain burnt lime clinker, take 70g burnt lime clinker, 10g condensed Hardener, 12g coagulation enhancer, 3g booster, put into the ball mill and ball mill until the specific surface area is 210m 2 / kg, then add 4g retarder, 1g water reducer, 1g heat conduction agent, continue ball milling for 35min, pass through 60 mesh sieve, and package static breaker.

example 3

[0030] Take 950g of industrial heavy calcium powder, 100g of iron oxide, mix them evenly, add 50g of deionized water, mix them evenly, mold them into shape, put them in a drying oven, dry them at 110°C to constant weight, and then transfer them to a muffle furnace , at a heating rate of 50°C / min to 1450°C, heat-preserved and calcined for 2 hours, cooled to room temperature, put into a pulverizer and pulverized, passed through a 40-mesh sieve to obtain burnt lime clinker, take 80g burnt lime clinker, 12g condensed Hardener, 15g coagulation enhancer, 4g booster, put into the ball mill and ball mill until the specific surface area is 240m 2 / kg, then add 5g retarder, 2g water reducer, 2g heat conduction agent, continue ball milling for 40min, pass through 60 mesh sieve, and package static breaker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com