Graphite product and its preparation method

A technology of graphite products and graphite powder, which is used in special containers for baking, special materials for cooking utensils, kitchen utensils, etc., can solve the problems of low thermal diffusivity and thermal conductivity, low thermal expansion coefficient, and large thermal expansion coefficient. Effects of high thermal diffusivity and thermal conductivity, low thermal expansion coefficient, and improved surface accuracy grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

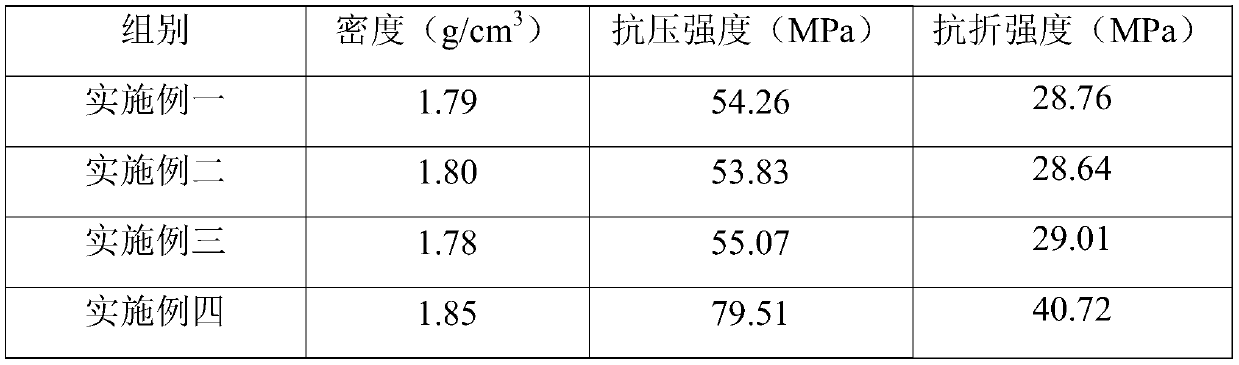

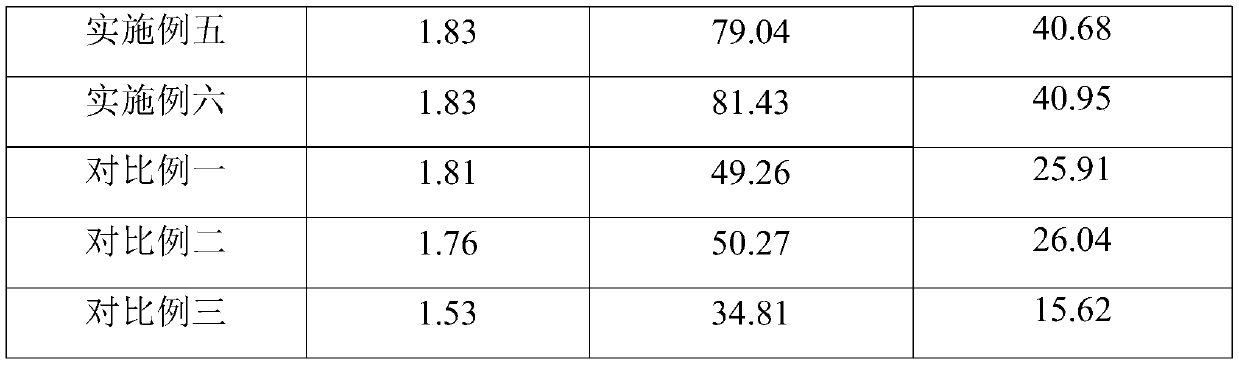

Examples

preparation example Construction

[0019] The invention provides a kind of preparation method of graphite product, comprises the steps:

[0020] S1: Pulverize the graphite material until the particle size is less than 100 μm, and then mix it with the binder in a mass ratio of 100:(5-10);

[0021] S2: Put the mixture obtained in step S1 into a molding mold, heat to 50-100°C for rigid molding, and the time for rigid molding is 25-35 minutes; wherein, the molding mold includes: wok mold, soup pot mold, pancake pan One or more of molds and grill pan molds;

[0022] S3: Take out the molded product obtained in step S2, and then carry out hot-press sintering to obtain graphite products; wherein, hot-press sintering includes the first heating process, the second heating and pressure raising process, constant temperature and constant pressure process and cooling process in sequence: the first heating process In the middle, the mechanical pressure is 20-22MPa, and the temperature is raised to 2500°C at a heating rate of...

Embodiment 1

[0029] The present embodiment provides a kind of preparation method of graphite product, comprises the steps:

[0030] S1: Pulverize the graphite material (graphite powder) to a particle size of less than 100 μm, and then mix it evenly with the binder at a mass ratio of 100:5;

[0031] S2: Put the mixture obtained in step S1 into the forming soup pot mold, heat to 50°C for rigid molding, and the time for rigid molding is 25 minutes;

[0032] S3: Take out the molded product obtained in step S2, and then carry out hot-press sintering to obtain graphite products; wherein, hot-press sintering includes the first heating process, the second heating and pressure raising process, constant temperature and constant pressure process and cooling process in sequence: the first heating process In the process, the mechanical pressure is 20MPa, and the temperature is raised to 2500°C at a heating rate of 20°C / min; during the second temperature rise and pressure increase and constant temperatu...

Embodiment 2

[0034] The present embodiment provides a kind of preparation method of graphite product, comprises the steps:

[0035] S1: Pulverize the graphite material (graphite powder) to a particle size of less than 100 μm, and then mix it with the binder at a mass ratio of 100:10;

[0036] S2: put the mixture obtained in step S1 into a forming soup pot mold, heat to 100°C for rigid molding, and the time for rigid molding is 35 minutes;

[0037]S3: Take out the molded product obtained in step S2, and then carry out hot-press sintering to obtain graphite products; wherein, hot-press sintering includes the first heating process, the second heating and pressure raising process, constant temperature and constant pressure process and cooling process in sequence: the first heating process In the middle, the mechanical pressure is 22MPa, and the temperature is raised to 2500°C at a heating rate of 40°C / min; during the second temperature rise and pressure increase and constant temperature and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com