Hot-pressing method for processing large-size super-hydrophobic cylindrical array capable of bouncing in droplet and cake shape

一种加工方法、超疏水的技术,应用在使原料颗粒化的方法、化学仪器和方法、图纹面的照相制版工艺等方向,能够解决难以实现产业化大面积加工、电火花加工效率低、高径比大等问题,达到易加工、密度小、高径比低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

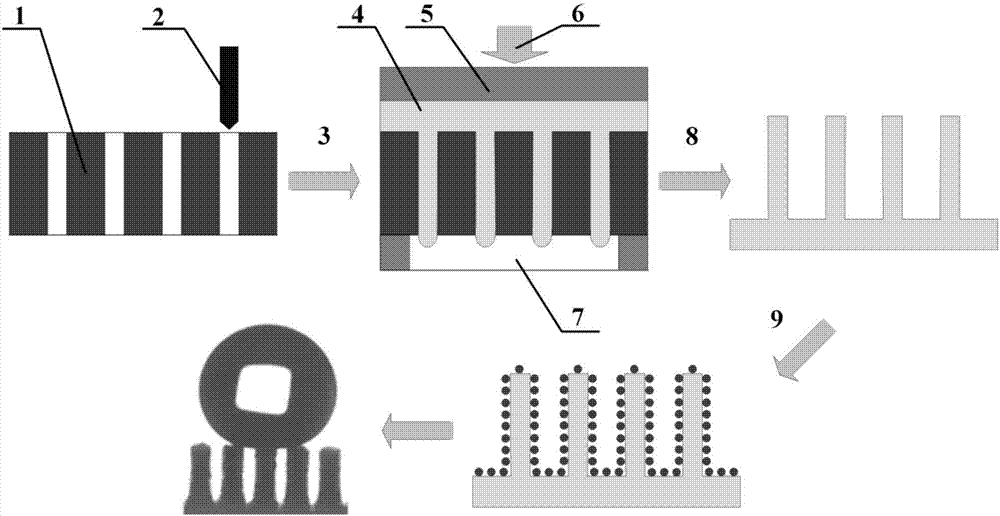

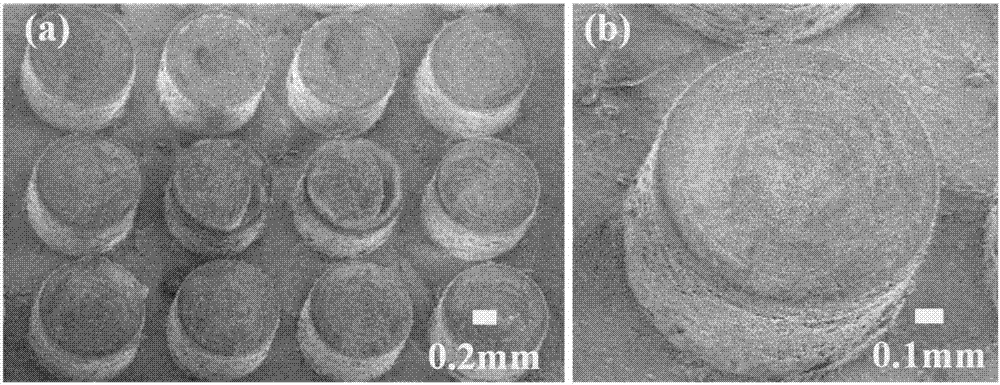

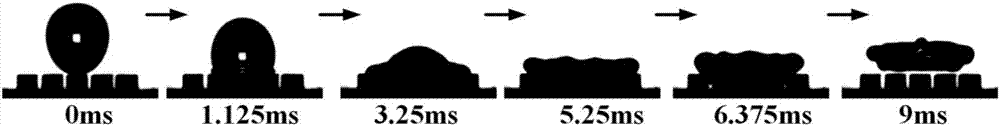

[0024] A superhydrophobic cylinder array that can realize droplet cake-like bouncing can be processed by hot-pressing replication method of porous array template, such as figure 1 As shown, the specific method is as follows:

[0025] (1) Preparation of hot-pressing mold: Grinding with 800# and 1500# sandpaper and ultrasonically cleaning 6061 aluminum plate (thickness 1mm) with deionized water to remove surface oxide layer and oil stain; use drilling technology to process diameter 1.05mm, column spacing 0.25mm, 1.0mm deep array through-hole structure, use 1500# sandpaper to remove surface burrs, and then blow dry after ultrasonic cleaning with deionized water;

[0026] (2) Hot pressing: Place the array through-hole mold prepared in step 1 on the lower substrate of the press, then fix the PP material on the upper pressing plate, then adjust the temperature of the substrate to 180°C, adjust the pressure to 2000Pa, and heat for 10 minutes Then remove the pressure, take out the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com