Automobile oil sump sealing gasket rubber material and preparation method thereof

A technology of rubber material and oil pan, applied in the direction of mechanical equipment, engine lubrication, engine components, etc., can solve the problem of not meeting the sealing requirements of the oil pan, harsh oil pan gasket, higher high temperature resistance and low pressure change requirements, etc. problems, to achieve excellent anti-aging and low-pressure deformation performance, good hardness, and improve the effect of heat resistance and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A gasket rubber material for an automobile oil pan, the raw materials of which include by weight:

[0024] 100 parts of nitrile rubber

[0026] 2 parts stearic acid

[0027] 1 part of 2,24-trimethyl-1,2-dihydroquinoline polymer

[0028] 1.5 parts of N-1,3-dimethylbutyl-N'-phenyl-p-phenylenediamine

[0029] Spray carbon black 80 parts

[0030] Dioctyl phthalate 5 parts

[0031] Dicumyl peroxide 1.5 parts

[0032] 2-mercaptobenzothiazole 2 parts

[0033] 1 part tetramethylthiuram disulfide

[0034] 0.2 parts of sulfur.

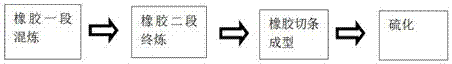

[0035] A preparation method of a gasket rubber material for an automobile oil pan, comprising the steps of:

[0036] a. One-stage mixing: Put nitrile rubber in an internal mixer and knead for 65s, then add zinc oxide, stearic acid, 2,24-trimethyl-1,2-dihydroquinoline polymer, N- 1,3-Dimethylbutyl-N'-phenyl-p-phenylenediamine, mixed to 85°C, then added spray carbon black and dioctyl phthalate, mixed to 110°C, at 110°C-...

Embodiment 2

[0040] A gasket rubber material for an automobile oil pan, the raw materials of which include by weight:

[0041] 100 parts of nitrile rubber

[0043] 1.5 parts of stearic acid

[0044] 1.5 parts of 2,24-trimethyl-1,2-dihydroquinoline polymer

[0045] 1.2 parts of N-1,3-dimethylbutyl-N'-phenyl-p-phenylenediamine

[0046] Spray carbon black 95 parts

[0047] Dioctyl phthalate 8 parts

[0048] 2.5 parts of dicumyl peroxide

[0049] 1.5 parts of 2-mercaptobenzothiazole

[0050] 1.5 parts of tetramethylthiuram disulfide

[0051] Sulfur 0.5 parts.

[0052] A preparation method of a gasket rubber material for an automobile oil pan, comprising the steps of:

[0053] a. One-stage mixing: Put nitrile rubber in an internal mixer and knead for 75s, then add zinc oxide, stearic acid, 2,24-trimethyl-1,2-dihydroquinoline polymer, N- 1,3-Dimethylbutyl-N'-phenyl-p-phenylenediamine, mixed to 95°C, then added spray carbon black and dioctyl phthalate, mixed ...

Embodiment 3

[0057] A gasket rubber material for an automobile oil pan, the raw materials of which include by weight:

[0058] 100 parts of nitrile rubber

[0059] 8 parts of zinc oxide

[0060] 1 part stearic acid

[0061] 2 parts of 2,24-trimethyl-1,2-dihydroquinoline polymer

[0062] 1 part of N-1,3-dimethylbutyl-N'-phenyl-p-phenylenediamine

[0063] Spray carbon black 90 parts

[0064] Dioctyl phthalate 10 parts

[0065] 2 parts dicumyl peroxide

[0066] 1 part of 2-mercaptobenzothiazole

[0067] 1.3 parts of tetramethylthiuram disulfide

[0068] 0.35 parts of sulfur.

[0069] A preparation method of a gasket rubber material for an automobile oil pan, comprising the steps of:

[0070] a. One-stage mixing: Put nitrile rubber in an internal mixer and knead for 70s, then add zinc oxide, stearic acid, 2,24-trimethyl-1,2-dihydroquinoline polymer, N- 1,3-Dimethylbutyl-N'-phenyl-p-phenylenediamine, mixed to 90°C, then added spray carbon black and dioctyl phthalate, mixed to 125°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com