Waterborne polyurethane three-protection paint for circuit board anticorrosion

A polyurethane conformal coating, water-based polyurethane technology, applied in the direction of polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of reducing work efficiency, irritating odor, yellowing, etc., to solve the problem of slow water volatilization, Improve curing speed and enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

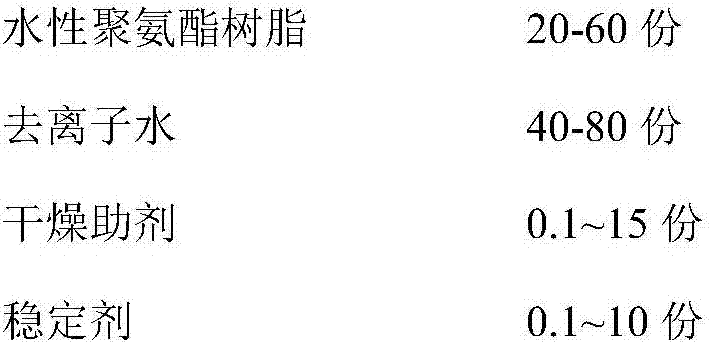

[0090] As a kind of embodiment of the present invention, by weight, its preparation raw material comprises:

[0091]

[0092]

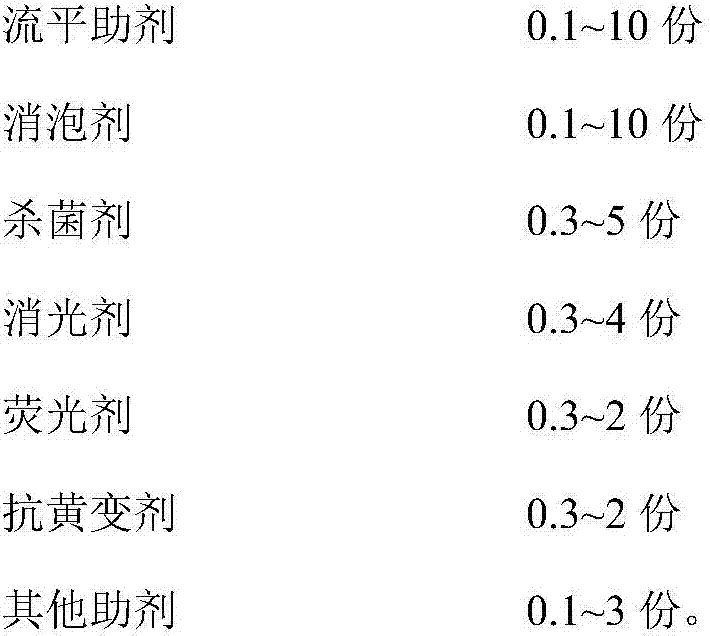

[0093] As a kind of embodiment of the present invention, by weight, its preparation raw material comprises:

[0094]

[0095] The second aspect of the present invention provides a method for preparing the above-mentioned water-based polyurethane conformal paint for anticorrosion of circuit boards, characterized in that, the steps of the method are:

[0096] 1) Take the water-based polyurethane resin and stabilizer according to the number of parts and mix and stir for 30 minutes at 20-35°C;

[0097] 2) Add deionized water in step 1), and mix and stir the drying aid until completely dissolved;

[0098] 3) In step 2), add leveling aid, defoamer, bactericide, matting agent, fluorescent agent, anti-yellowing agent and mix well;

[0099] 4) Add other additives in step 3) and mix and stir evenly.

Embodiment approach 1

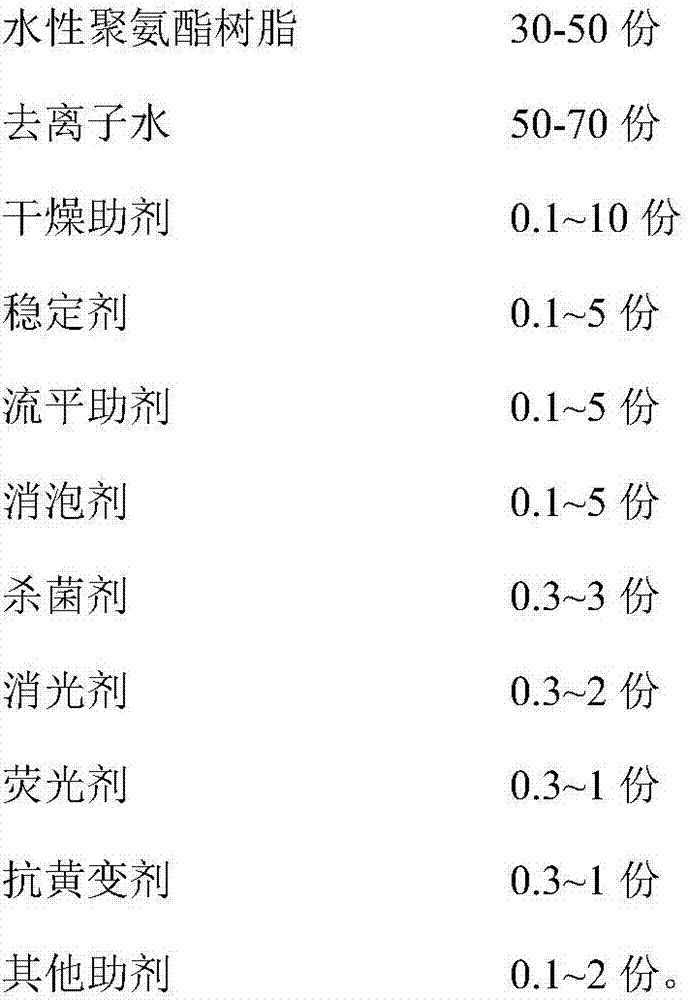

[0100] Embodiment 1: This embodiment provides a water-based polyurethane conformal paint for anticorrosion of circuit boards. In parts by weight, its preparation raw materials include:

[0101]

[0102]

Embodiment approach 2

[0103] Embodiment 2. A water-based polyurethane conformal paint for anticorrosion of circuit boards described in Embodiment 1, in parts by weight, its preparation raw materials include:

[0104]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com