Composite material for remedying mine wasteland as well as preparation method and application of composite material

A composite material and wasteland technology, which is applied in the field of composite materials for repairing mine wasteland and its preparation, can solve problems such as long time, and achieve the effects of easy control, easy availability of raw materials, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

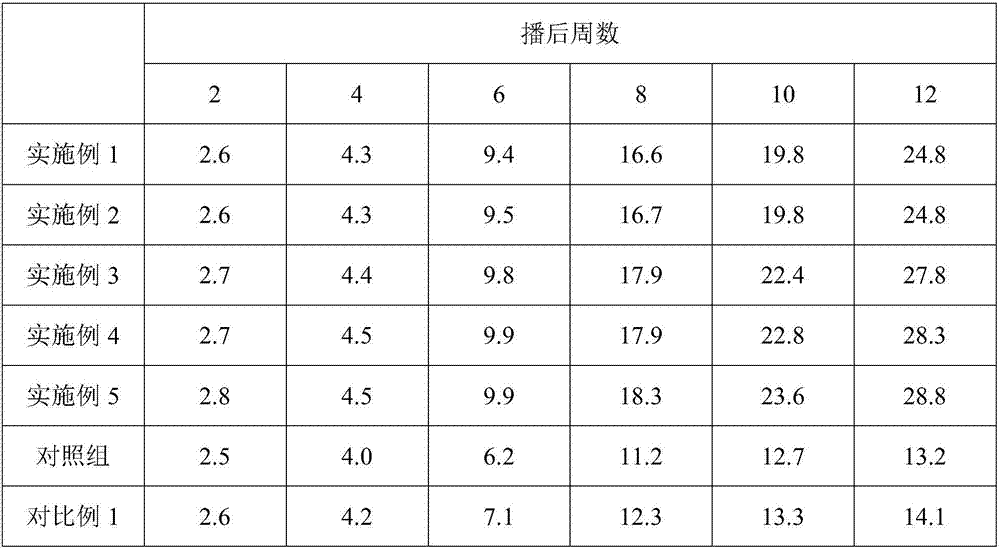

Embodiment 1

[0024] In an embodiment of the present invention, a composite material for repairing abandoned mine sites includes the following raw materials: 30 kg of apatite, 22 kg of wood vinegar, 31 kg of humic acid, 13 kg of disodium edetate, and 1 kg of azoxystrobin.

[0025] Crush the apatite, pass it through a 100-mesh sieve, add an acetic acid solution 10 times its mass, then raise the temperature to 70°C and heat and stir at this temperature at a stirring speed of 300r / min for 1.5h to obtain the treated apatite The solvent of the acetic acid solution is water, and the mass concentration of the acetic acid solution is 20%. Mix wood vinegar and azoxystrobin and stir at a stirring speed of 100r / min for 1.8h, then heat to 68°C and stir at this temperature for 0.5h; filter the filtrate to obtain mixture A. Mix humic acid with 22% aqueous solution of citric acid with a mass concentration 5 times its mass, heat to 88°C, and stir at this temperature for 55min at a stirring speed of 200r / mi...

Embodiment 2

[0027] In an embodiment of the present invention, a composite material for repairing abandoned mine sites includes the following raw materials: 40 kg of apatite, 30 kg of wood vinegar, 39 kg of humic acid, 21 kg of disodium edetate, and 5 kg of azoxystrobin.

[0028] Crush the apatite, pass it through a 150-mesh sieve, then add 12 times the mass of acetic acid solution, then raise the temperature to 75°C and heat and stir at this temperature at a stirring speed of 320r / min for 1.8h to obtain the apatite-treated product The solvent of the acetic acid solution is water, and the mass concentration of the acetic acid solution is 25%. Mix wood vinegar liquid with azoxystrobin and stir at a stirring speed of 150r / min for 2h, then heat to 70°C and stir at this temperature for 0.7h; filter the filtrate to obtain mixture A. Mix humic acid with 25% citric acid aqueous solution with a mass concentration 6 times its mass, heat to 90°C, and stir at this temperature for 60min at a stirring ...

Embodiment 3

[0030] In an embodiment of the present invention, a composite material for repairing abandoned mine sites includes the following raw materials: 32 kg of apatite, 24 kg of wood vinegar, 33 kg of humic acid, 15 kg of disodium edetate, and 2 kg of azoxystrobin.

[0031] Crush the apatite, pass it through a 150-mesh sieve, then add an acetic acid solution 11 times its mass, then raise the temperature to 72°C and heat and stir at this temperature at a stirring speed of 320r / min for 1.8h to obtain the treated apatite The solvent of the acetic acid solution is water, and the mass concentration of the acetic acid solution is 25%. Mix wood vinegar and azoxystrobin and stir at a stirring speed of 150r / min for 1.9h, then heat to 69°C and stir at this temperature for 0.7h; filter the filtrate to obtain mixture A. Mix humic acid with 25% citric acid aqueous solution with a mass concentration 6 times its mass, heat to 90°C, and stir at this temperature for 60min at a stirring speed of 220r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com