Low-cost anti-stabbing and flame-retarding dacron textile fibers and preparation method thereof

A flame-retardant polyester and textile fiber technology, which is applied in the field of low-cost stab-resistant flame-retardant polyester textile fiber and its preparation, can solve the problems of poor comprehensive performance of textile fibers, and achieve good flame-retardant performance, high flame-retardant efficiency, and energy saving resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

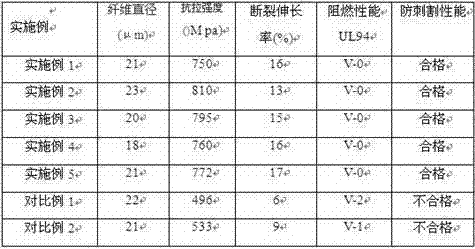

Examples

Embodiment 1

[0026] In this example, the low-cost stab-resistant and flame-retardant polyester textile fiber is prepared from the following raw materials in parts by weight: 60 parts of polyester, 20 parts of magnesium oxide, 10 parts of ethanol solution of perfluorodecyltrichlorosilane, and 2 parts of magnesium sulfate , 5 parts of nano-montmorillonite, 2 parts of dispersant, 2 parts of diffusion accelerator;

[0027] Among them, the dispersant is a mixture of sodium dodecylsulfate and sodium dodecylbenzenesulfonate, the mass ratio of sodium dodecylsulfate and sodium dodecylbenzenesulfonate is 1.5:2.5; the diffusion accelerator is formic acid ;

[0028] The preparation method of the low-cost anti-stab and flame-retardant polyester textile fiber of this embodiment comprises the following steps:

[0029] S1. Weighing each raw material according to parts by weight;

[0030] S2, placing the magnesium oxide in an ultrasonic continuous flow cell pulverizer for ultrasonic pulverization, drying...

Embodiment 2

[0036] In this example, the low-cost stab-resistant and flame-retardant polyester textile fiber is prepared from the following raw materials in parts by weight: 90 parts of polyester, 35 parts of magnesium oxide, 20 parts of ethanol solution of perfluorodecyltrichlorosilane, and 7 parts of magnesium sulfate , 10 parts of nano-montmorillonite, 5 parts of dispersant, 5 parts of diffusion accelerator;

[0037] Among them, the dispersant is a mixture of sodium dodecylsulfate and sodium dodecylbenzenesulfonate, the mass ratio of sodium dodecylsulfate and sodium dodecylbenzenesulfonate is 1.5:2.5; the diffusion accelerator is acetic acid ;

[0038] The preparation method of the low-cost anti-stab and flame-retardant polyester textile fiber of this embodiment comprises the following steps:

[0039]S1. Weighing each raw material according to parts by weight;

[0040] S2. Place magnesium oxide in an ultrasonic continuous flow cell pulverizer for ultrasonic pulverization and drying to...

Embodiment 3

[0046] In this embodiment, the low-cost anti-stab and flame-retardant polyester textile fiber is composed of the following raw materials in parts by weight: 75 parts of polyester, 28 parts of magnesium oxide, 15 parts of ethanol solution of perfluorodecyltrichlorosilane, 5 parts of magnesium sulfate, nano-molybdenum 7 parts of soil removal, 3.5 parts of dispersant, 3.5 parts of diffusion accelerator;

[0047] Among them, the dispersant is a mixture of sodium dodecylsulfate and sodium dodecylbenzenesulfonate, the mass ratio of sodium dodecylsulfate and sodium dodecylbenzenesulfonate is 1.5:2.5; the diffusion accelerator is lactic acid ;

[0048] The preparation method of the low-cost anti-stab and flame-retardant polyester textile fiber of this embodiment comprises the following steps:

[0049] S1. Weighing each raw material according to parts by weight;

[0050] S2. Place the magnesium oxide in an ultrasonic continuous flow cell pulverizer for ultrasonic pulverization, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com