Filter paper having boric acid adsorption and desorption functions and preparation method thereof

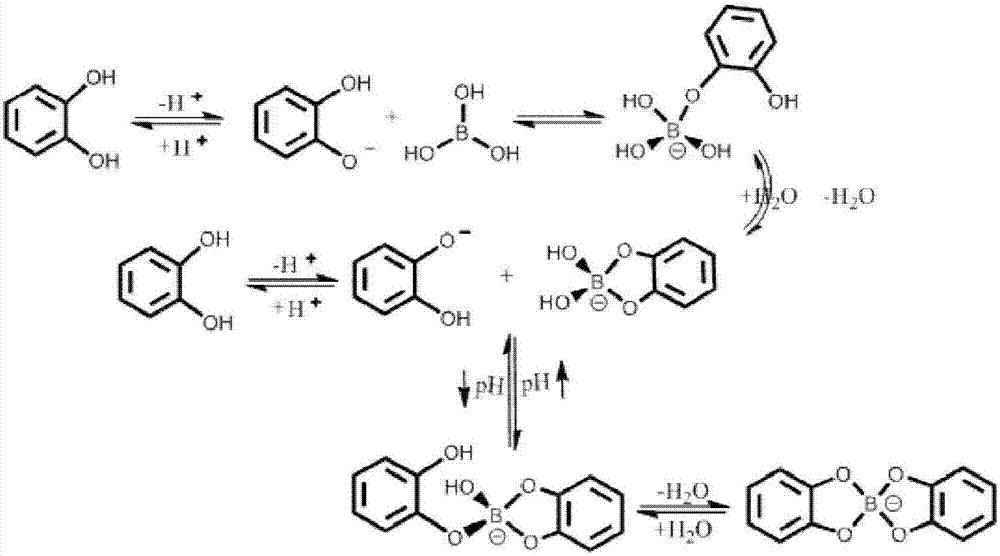

A technology of adsorption, desorption and boric acid, applied in the field of functional paper, can solve the problems of narrow application range of functional paper, and achieve the effects of good popularization and application value, simple preparation method, simple process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Tear the larch fiber pulp board into small samples with a diameter of about 4 to 5 cm, put a certain amount of water in the beater, and prepare a slurry with a pulp concentration of 2%, and stir in the beater to obtain a beating degree of The 30% cellulose pulp is squeezed and filtered to remove most of the moisture in the pulp, and dedried in a dehydrator to obtain a pulp for papermaking with an absolute dryness of 25%.

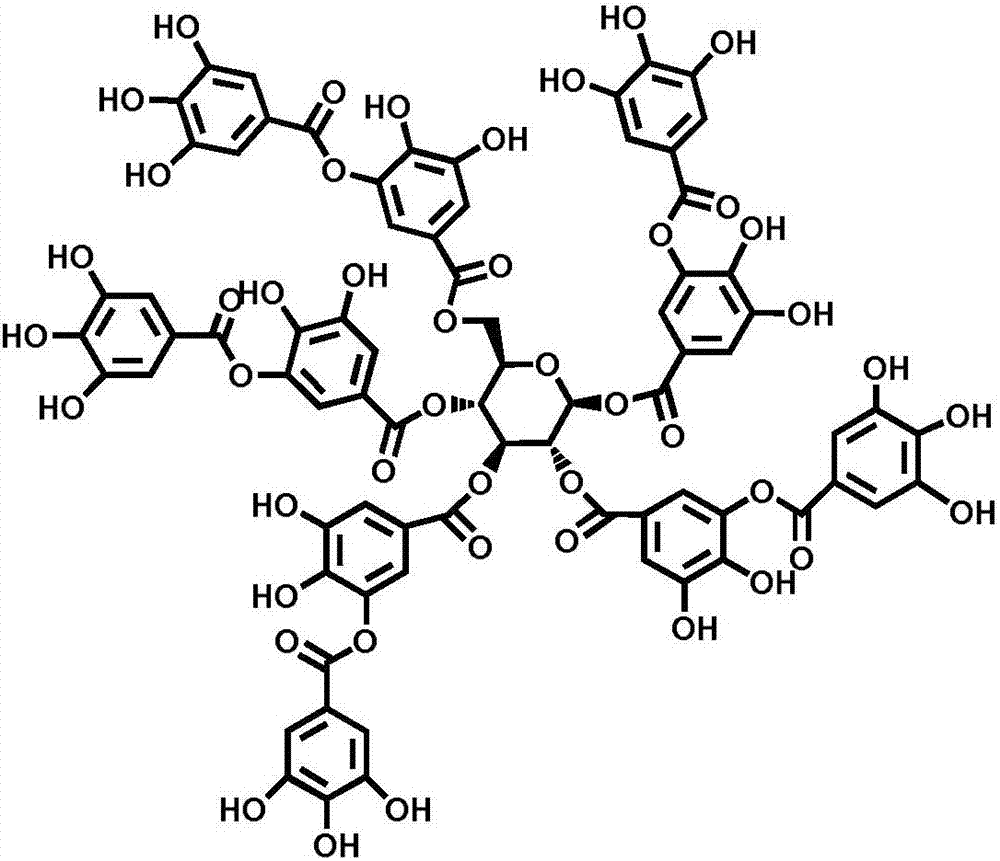

[0035] Take 2 parts of slurry with an absolute dryness of 25%, put them in 2000mL of water, and use a decomposer to decompose for 5 minutes, then add 0.5 parts of tannic acid aqueous solution with a mass concentration of 10% to the slurry, and 0.01 parts with a mass concentration of 1‰ The cationic polyacrylamide was stirred at a stirring rate of 200r / min for 10 minutes, the slurry was placed in a paper machine to make paper, and the paper was dried in a dryer at 60°C to obtain the final functional filter paper.

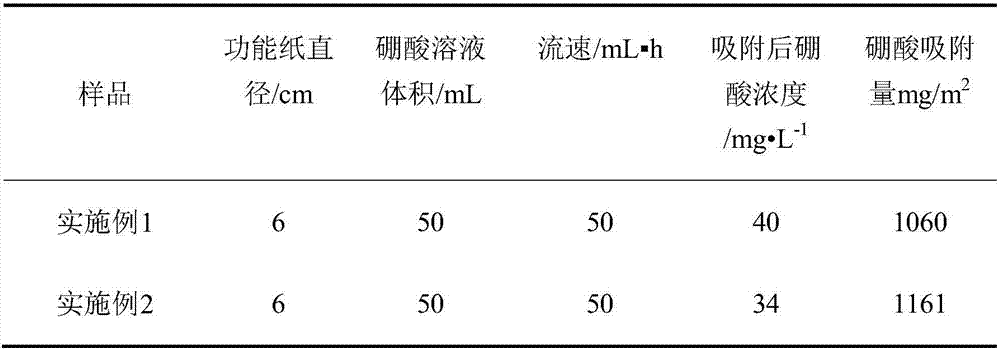

[0036] Under other conditions being t...

Embodiment 2

[0038] Tear the poplar fiber pulp board into small samples with a diameter of about 4 to 5 cm, put it in a beater and then add a certain amount of water to prepare a slurry with a 2% pulp concentration, stir in the beater to obtain a beating degree of 20 % of the cellulose pulp, under the action of extrusion filtration, most of the water in the pulp is removed, and dedried in a dehydrator to obtain a pulp for papermaking with an absolute dryness of 26%.

[0039] Take 2 parts of slurry with an absolute dryness of 26%, put them in 2000mL of water, and use a deconcentrator to decompose for 5 minutes, then add 5 parts of tannic acid aqueous solution with a mass concentration of 11% to the slurry, and 0.5 parts with a mass concentration of 1.5‰ The cationic starch was stirred at a stirring rate of 200r / min for 10min, the slurry was placed in a paper machine to make paper, and the paper was dried in a dryer at 70°C to obtain the final functional filter paper.

[0040] Under other co...

Embodiment 3

[0042] Tear the bagasse fiber pulp board into small samples with a diameter of about 4 to 5 cm, put it in a beater and add a certain amount of water to prepare a slurry with a 2% pulp concentration, stir in the beater, and obtain a beating degree of 40 % of the cellulose pulp, under the action of extrusion filtration, remove most of the water in the pulp, and dedry in a dehydrator to obtain pulp for papermaking with an absolute dryness of 27%.

[0043] Take 5 parts of slurry with an absolute dryness of 27%, put it in 2000mL of water, and use a deflagger to decompose it for 5 minutes, then add 6 parts of tannic acid aqueous solution with a mass concentration of 12% to the slurry, and 0.2 parts with a mass concentration of 2‰ After stirring for 10 minutes at a stirring rate of 200r / min, the slurry was placed in a paper machine to make paper, and the paper was dried in a dryer at 80°C to obtain the final functional filter paper.

[0044] Under other conditions being the same, no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com