Biological aerated filter, its construction method and method for treating water with the biofilter constructed by the method

A technology of biological aerated filter and its construction method, which is applied in the field of using double-layer biological aerated filter to domesticate low-temperature nitrifying bacteria to pretreat ammonia nitrogen in water source water, which can solve the problems of unstable operation, aggravated ammonia nitrogen pollution of water source water, and poor ammonia nitrogen removal effect And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

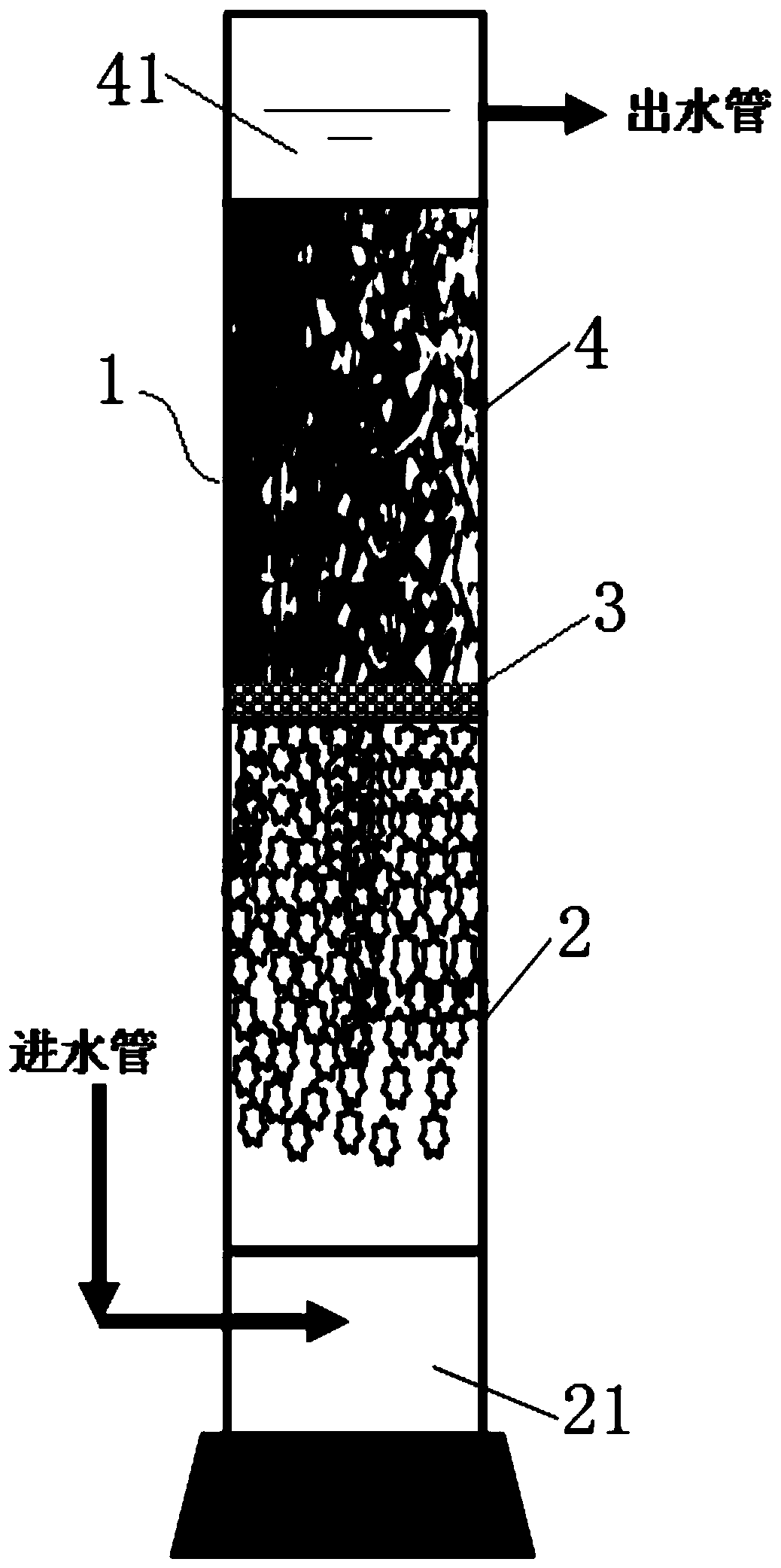

[0081] Example 1 Stable operation at room temperature, lightweight filler-zeolite double-layer biological aerated filter

[0082] The inner diameter of the double-layer biological aerated filter is 100mm, in which: the height of the buffer water distribution area in the lower layer of the filter is 0.2m; the lower filter layer is a light filler (polyethylene) layer with a height of 1m (usually 1-2.5m, preferably 1- 1.5m, taking 1m as an example in the embodiment of the present invention), the filling rate of light filler is 80% (usually 80-90%), and the bulk density is 150kg / m 3 ; The porous filter interlayer is composed of a porous filter plate and a pebble layer with a particle size of 3-6mm fixedly placed on the upper part of it, and the height is 0.2m. The layer is laid from the bottom to the top in the order of the particle size; the upper filter layer It is a zeolite filter layer with a zeolite particle size of 1 to 3 mm, a zeolite packing height of 1 m (usually 1 to 1.5 m, ...

Embodiment 1A

[0091] Example 1A In situ domestication of low-temperature nitrifying bacteria

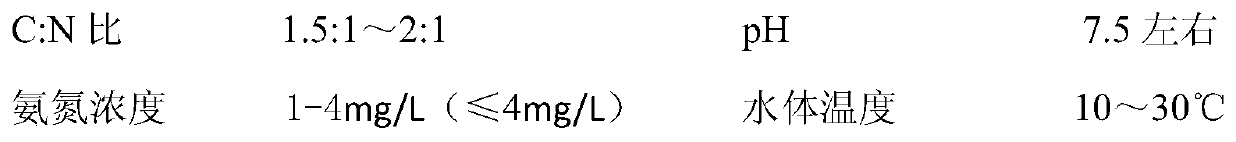

[0092] Water quality of the source water to be treated:

[0093]

[0094]

[0095] In this embodiment, the ammonia nitrogen concentration of the source water to be treated is described by taking 1.7 mg / L as an example, and other source waters ≤ 4 mg / L are suitable for the present invention.

[0096] To the stable double-layer biological aerated filter (light-weight filler-zeolite double-layer biological aerated filter) in Example 1, the temperature was maintained at 3°C (usually at 1 to 5°C). The source water to be treated flows into the water distribution area from the bottom of the double-layer biological aerated filter through the inlet pipe, and runs upward; for aeration, the air-water ratio is 2.5:1 (usually 2:1~3:1), hydraulic retention For 60 minutes (usually 30-60 minutes), the mixed flow of gas and water passes through the lower lightweight filler filter layer, the middle porous filter plate ...

Embodiment 2

[0100] Example 2 Rapid domestication of low-temperature nitrifying bacteria

[0101] 1. Prepare backwash concentrate

[0102] In the process of backwashing the stable running lightweight filler-zeolite double-layer biological aerated filter in Example 1, the backwash water was collected, and the ratio of the amount of backwash water to the volume of the filter was 2.5:1 ( Usually 1.5-3:1); then the collected backwash water is placed at room temperature (20-30℃) for 20-30min, the supernatant is removed, and the lower backwash concentrate is obtained, where the backwash concentrate and The volume ratio of the collected backwash water is 10:100 (usually 10-20:100).

[0103] The backwashing of the biological filter of the present invention is described by taking the method of first air washing, then air-water combined washing, and then water washing as an example, and other methods of backwashing are also applicable to the present invention.

[0104] 2. The first low-temperature inductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com