A method and system for optimizing the group performance of ternary batteries based on voltage secondary sorting

A technology of secondary sorting and optimization method, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., it can solve the problem of multi-parameter sorting method, which has many parameters, large battery pack pressure difference, overcharge and over-discharge of cells. and other problems, to achieve the effect of simple and efficient optimization method, good battery performance, and good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

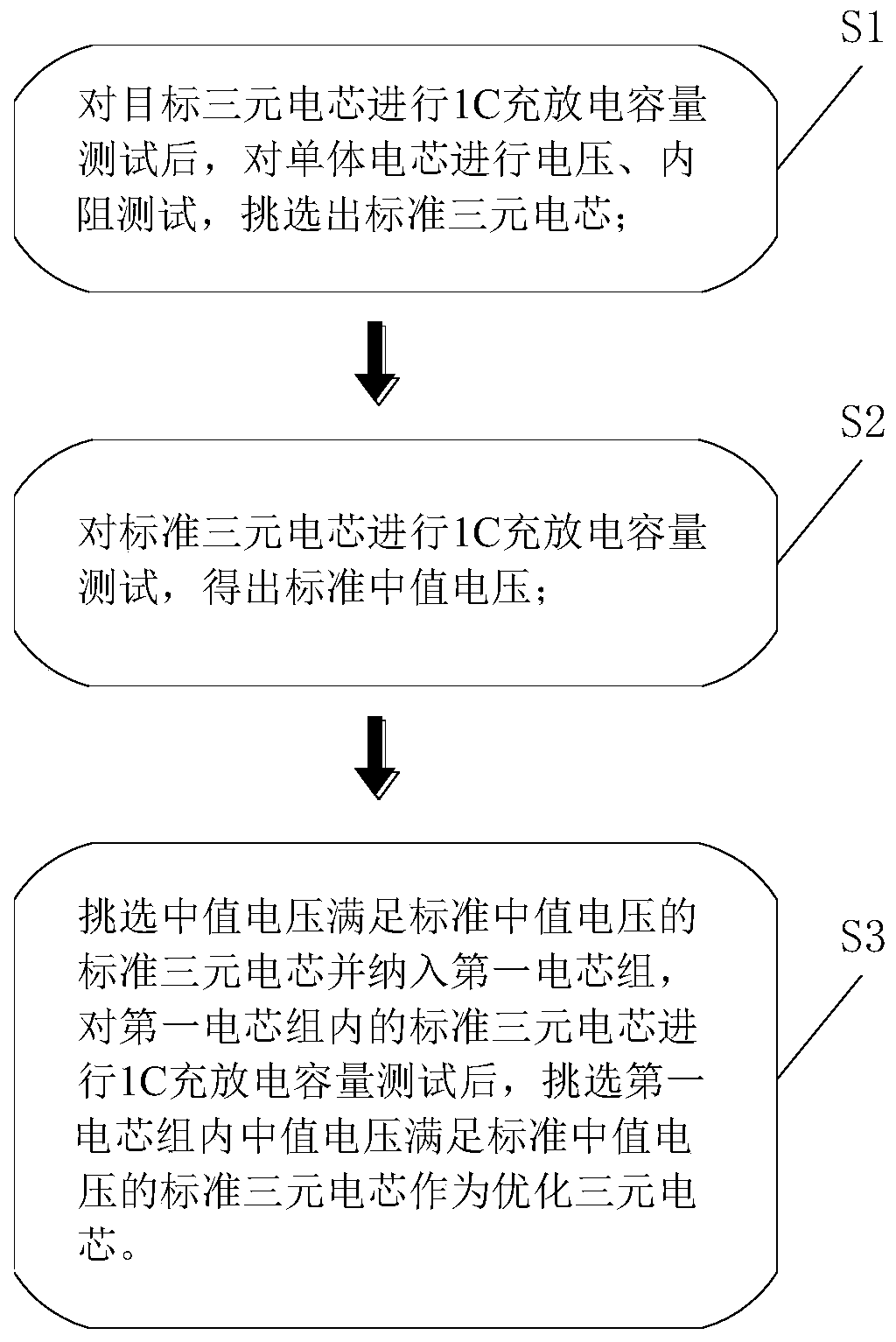

[0030] Such as figure 1 , figure 2 as shown, figure 1 , figure 2 A method and system for optimizing the group performance of ternary cells based on voltage secondary sorting proposed by the present invention.

[0031] refer to figure 1 , the method for optimizing the group performance of ternary cells based on voltage secondary sorting proposed by the present invention includes the following steps:

[0032] S1. After testing the 1C charge and discharge capacity of the target ternary battery, test the voltage and internal resistance of the single battery, and select the standard ternary battery;

[0033] In this embodiment, step S1 specifically includes:

[0034] Carry out 1C 36A charge and discharge capacity test on the ternary battery cell with a nominal capacity of 36Ah, in which the charge and discharge voltage range is 3.0-4.2V, test the voltage and internal resistance of the single cell, and select a capacity of 35.5-36.5Ah , the voltage is greater than 4.10V, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com