Flexible and tailorable solid super capacitor and preparation method thereof

A supercapacitor, solid-state technology, applied in the field of flexible and tailorable solid-state supercapacitors and its preparation, can solve the problems of specific capacity dependence, slow self-discharge, and great difference in specific capacity, and achieve fast and effective transmission and accumulation, long self-discharge The effect of performance, excellent flexibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

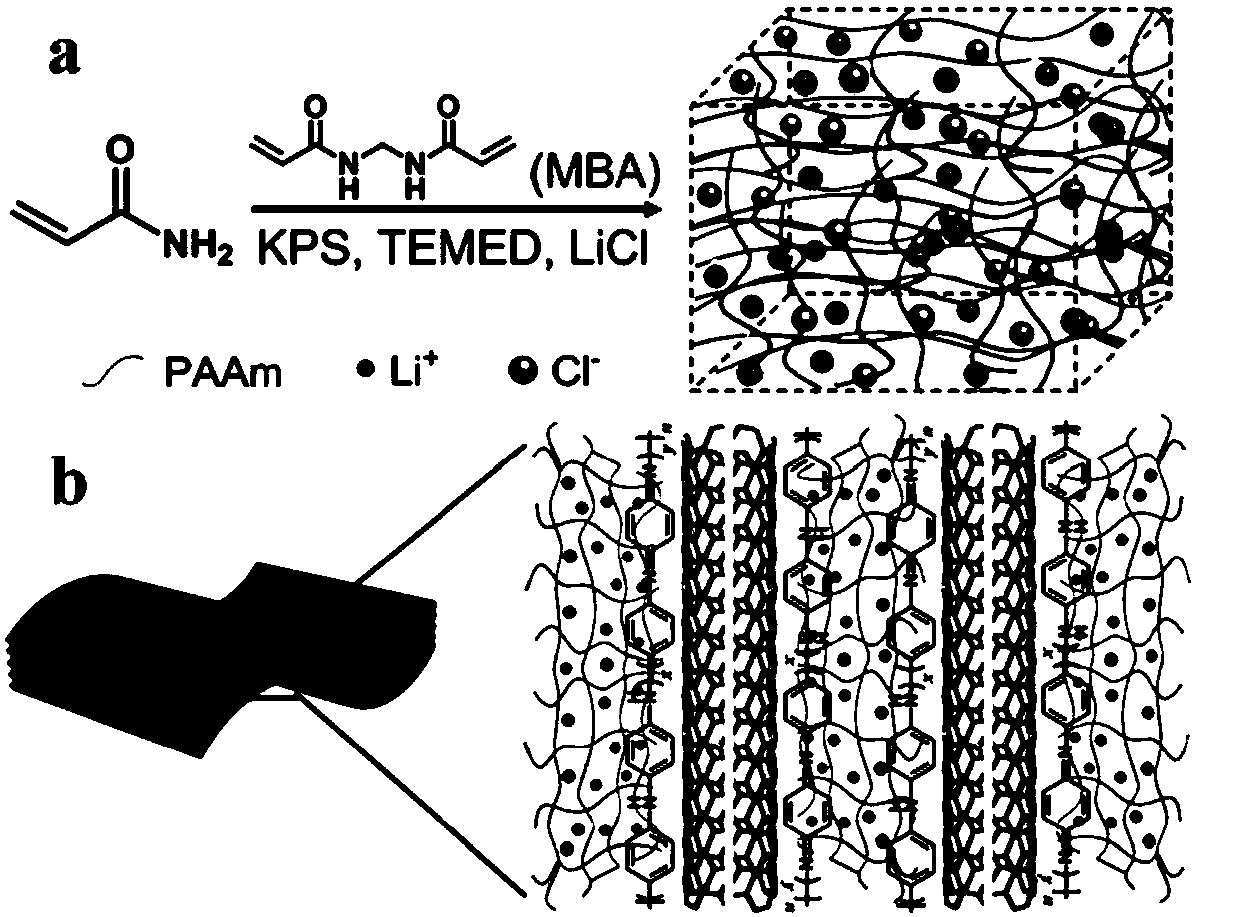

[0066] A flexible and tailorable solid-state supercapacitor based on polymer hydrogel, the preparation process is as follows figure 1 As shown, the specific steps are:

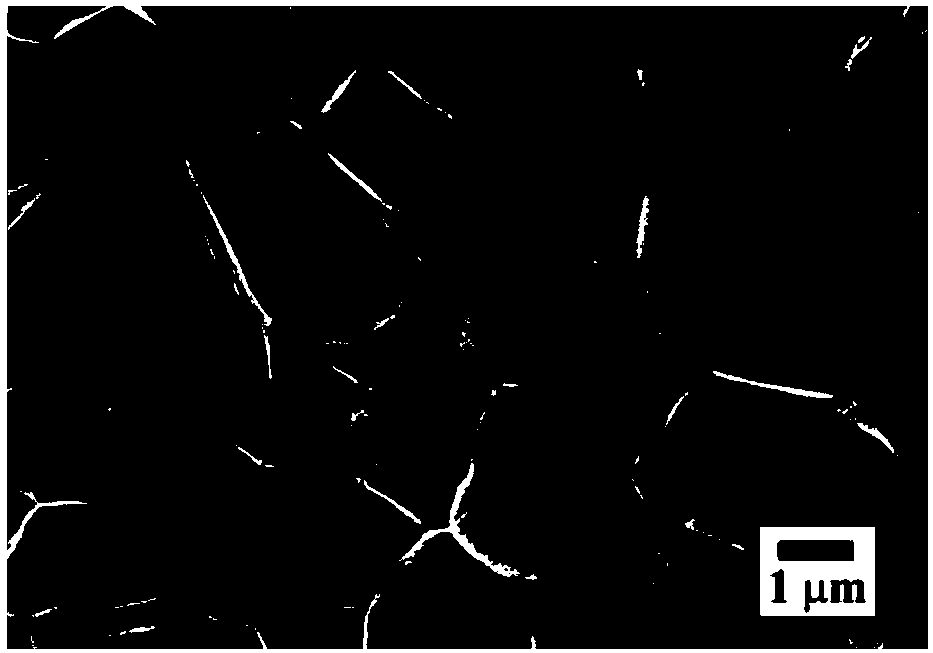

[0067] (1) Polyaniline was deposited on both sides of the 10 μm carbon nanotube film by electrochemical deposition, and 0.2mol L -1 Aniline and 0.5mol L -1 Concentrated sulfuric acid was dissolved in deionized water, and stirred evenly to obtain a sulfuric acid solution of aniline. Using a three-electrode system, using aniline sulfuric acid solution as the electrolyte, carbon nanotube film as the working electrode, saturated calomel electrode as the reference electrode, and platinum sheet as the counter electrode, the carbon nanotube / polyaniline composite film was obtained by cyclic scanning. ;

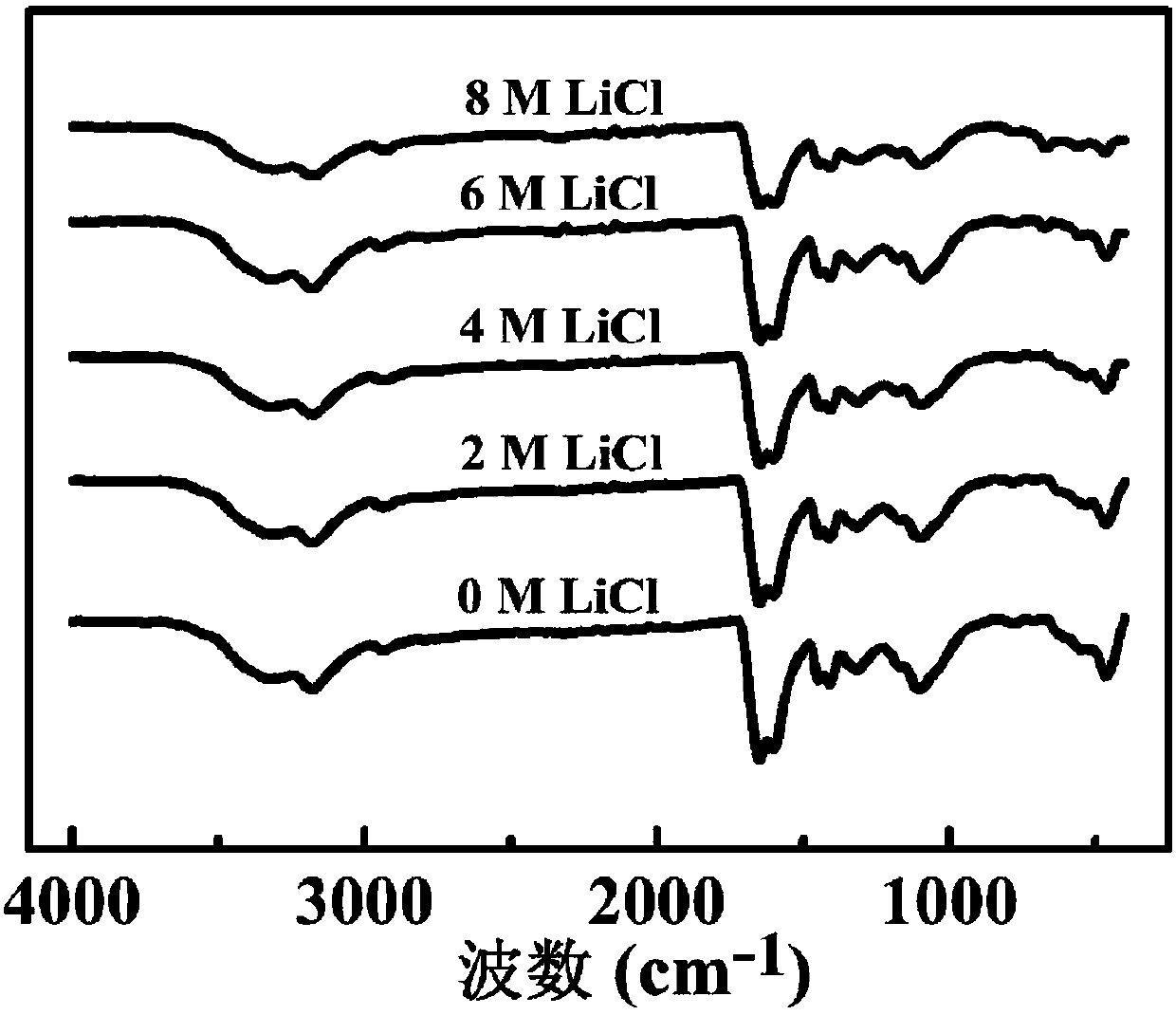

[0068] (2) The carbon nanotube film / polyaniline composite membrane obtained in step (1) is coated with polyacrylamide / lithium chloride hydrogel prepolymerization liquid by pressure difference method, and after cros...

Embodiment 2

[0073] A method for preparing a flexible and tailorable solid-state supercapacitor based on polymer hydrogel, the specific steps are:

[0074] (1) Deposit polyaniline on both sides of the carbon nanotube film by electrochemical deposition to obtain a carbon nanotube / polyaniline composite film;

[0075] (2) in step (1) the gained carbon nanotube amine composite membrane permeates the polyacrylamide / lithium chloride hydrogel pre-polymerization liquid, after cross-linking polymerization, obtains the polyacrylamide / lithium chloride hydrogel electrolyte Carbon nanotube / polyaniline composite film;

[0076] (3) Coating and polymerizing the polyacrylamide / lithium chloride hydrogel pre-polymerization solution in the middle and both sides of the carbon nanotube / polyaniline composite film obtained in step (2), after cross-linking and polymerization, the polymer water-based Flexible, tailorable solid-state supercapacitors in gels.

[0077] The thickness of the carbon nanotube film is 8 ...

Embodiment 3

[0091] A method for preparing a flexible and tailorable solid-state supercapacitor based on polymer hydrogel, the specific steps are:

[0092] (1) Deposit polyaniline on both sides of the carbon nanotube film by electrochemical deposition to obtain a carbon nanotube / polyaniline composite film;

[0093] (2) The carbon nanotube / polyaniline composite membrane obtained in step (1) is infiltrated into the polyacrylamide / lithium chloride hydrogel prepolymerization solution, and after cross-linking polymerization, the infiltrated polyacrylamide / lithium chloride hydrogel is obtained Electrolyte carbon nanotube film / polyaniline composite film;

[0094] (3) Coating and polymerizing the polyacrylamide / lithium chloride hydrogel pre-polymerization solution in the middle and both sides of the carbon nanotube film / polyaniline composite film obtained in step (2), after cross-linking and polymerization, a polymer based Flexible, tailorable solid-state supercapacitors from hydrogels.

[0095]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com