Catalyst for preparing decahydronaphthalene by hydrogenation of tetrahydronaphthalene, preparation method and application thereof

A catalyst, a technology for hydrogen preparation, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. The problems of low trans-cis ratio of naphthalene and easy poisoning of the catalyst can increase the stability, improve the yield and purity, and reduce the dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

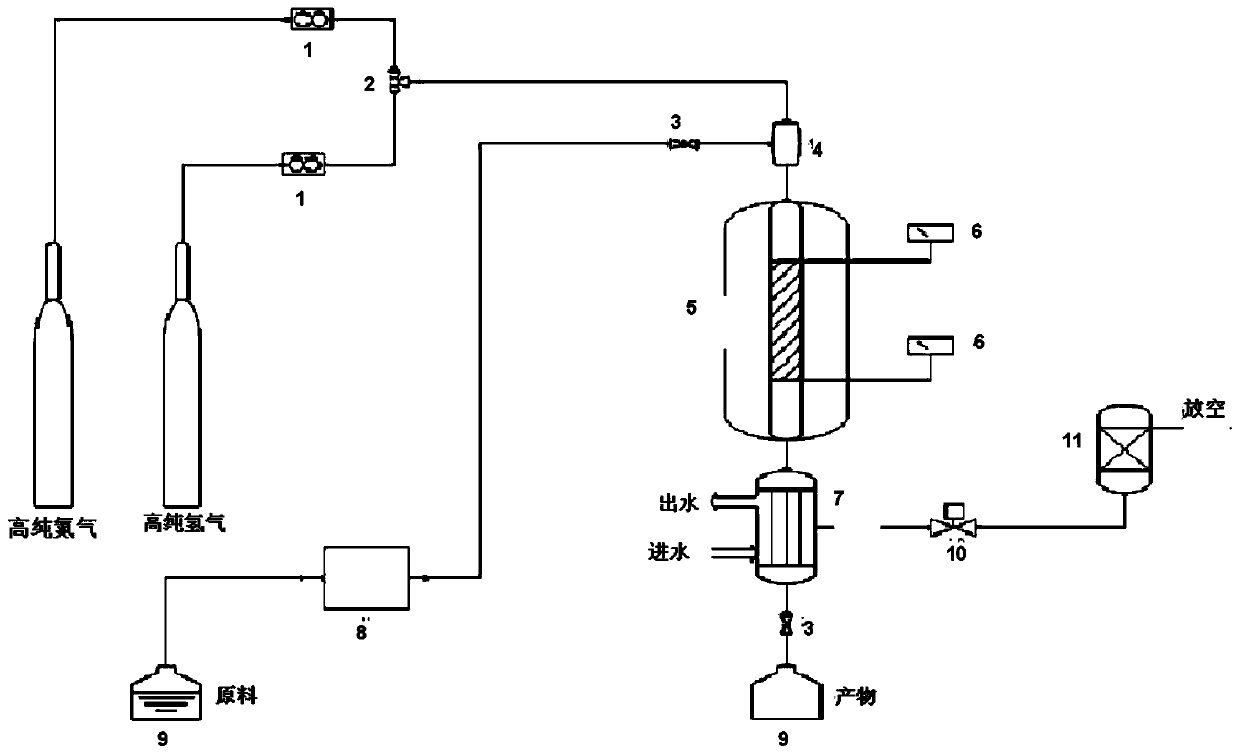

Method used

Image

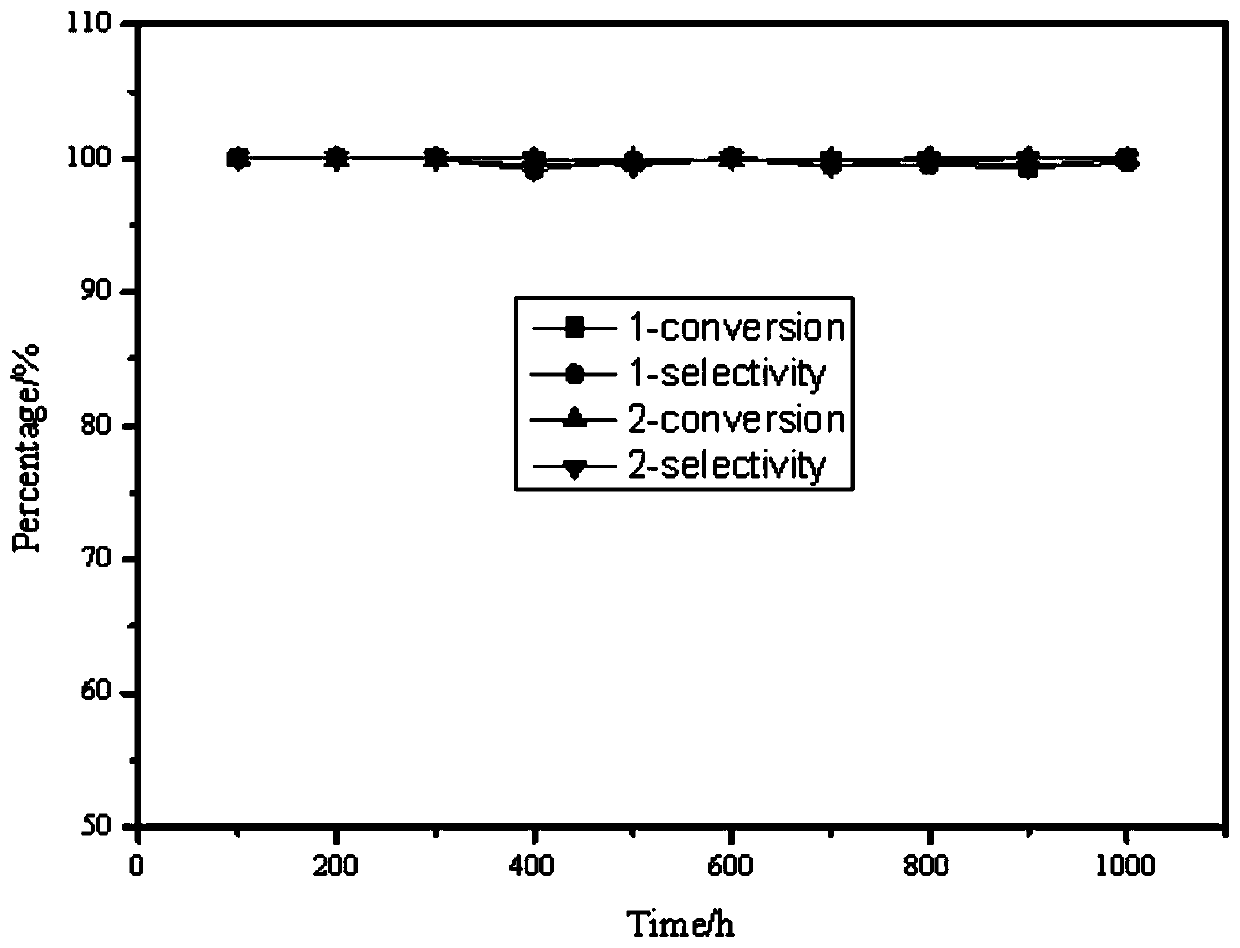

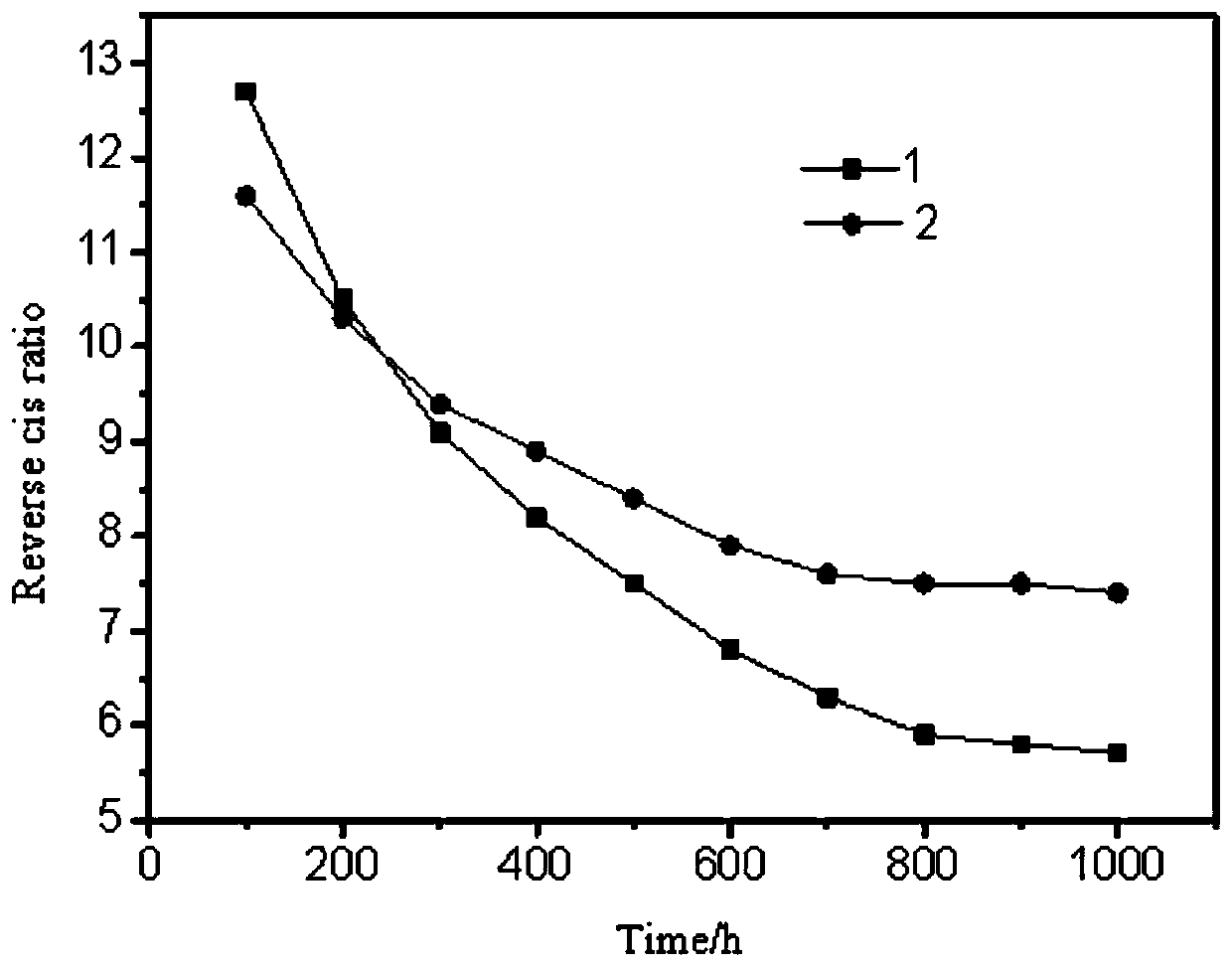

Examples

Embodiment 1

[0048] (1) Al 2 o 3 The carrier was ball milled for 5 hours, passed through a 200-mesh sieve, and then calcined in an air atmosphere at 450°C for 5 hours to obtain carrier A1;

[0049] (2) Weigh 11.5g of magnesium nitrate hexahydrate and dissolve it in 50ml of deionized water to obtain an additive solution, adjust its pH value to 4 with nitric acid solution, and place it in a 2.5L plastic beaker; weigh 28.11g of carrier A1 and quickly pour Stir in a plastic beaker for 30 minutes, then stand at room temperature for 12 hours, dry in an oven at 100°C for 12 hours, take it out and bake it in an air atmosphere at 450°C for 5 hours to obtain carrier B1;

[0050] (3) Weigh 2 g of palladium dichloride and dissolve it in 200 ml of deionized water, add hydrochloric acid solution dropwise to adjust its pH to 4, and obtain (a) solution. Measure 15ml of (a) solution into a 2.5L plastic beaker, then add 35ml of deionized water and stir; quickly pour the carrier B1 prepared in (2) into the...

Embodiment 2

[0053] (1) Al 2 o 3 The carrier was ball milled for 5 hours, passed through a 200-mesh sieve, and then calcined in an air atmosphere at 450°C for 5 hours to obtain carrier A2;

[0054] (2) Take by weighing 4.5g of cerium nitrate hexahydrate and dissolve it in 50ml of deionized water to obtain an additive solution, adjust its pH value to 4 with nitric acid solution, place it in a 2.5L plastic beaker; weigh 28.11g of carrier A2 and quickly pour Put it into a plastic beaker and stir for 30 minutes, then leave it to age at room temperature for 12 hours, dry it in an oven at 100°C for 12 hours, take it out and bake it in an air atmosphere at 450°C for 5 hours to obtain carrier B2;

[0055] (3) Measure 15ml of the solution (a) prepared in Case 1 and add it to a 2.5L plastic beaker, then add 35ml of deionized water and mix well; quickly pour the carrier B2 prepared in (2) into the plastic beaker Stir and mix for 30 minutes, then stand and age at room temperature for 12 hours, and d...

Embodiment 3

[0058] (1) Al 2 o 3 The carrier was ball milled for 5 hours, passed through a 200-mesh sieve, and then calcined in an air atmosphere at 450°C for 5 hours to obtain carrier A3;

[0059](2) Dissolve 6.3g of zirconium nitrate pentahydrate in 50ml of deionized water to obtain an additive solution, adjust its pH value to 4 with nitric acid solution, place it in a 2.5L plastic beaker; weigh 28.11g of carrier A3 and quickly pour it into the plastic Stir and mix in a beaker for 30 minutes, then stand and age at room temperature for 12 hours, dry in an oven at 100°C for 12 hours, take it out and bake it in an air atmosphere at 450°C for 5 hours to obtain carrier B3;

[0060] (3) Measure 25ml of the solution (a) prepared in Case 1 and add it to a 2.5L plastic beaker, then add 25ml of deionized water and stir to mix; quickly pour the carrier B3 prepared in (2) into the plastic beaker Stir and mix for 30 minutes, then stand and age at room temperature for 12 hours, and dry at 120°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com