Table model numerical control cutting machine

A cutting machine, desktop technology, applied in manufacturing tools, plasma welding equipment, welding equipment and other directions, can solve the problems of unsatisfactory dust removal effect, complex cleaning structure, difficult to clean waste, etc. Cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

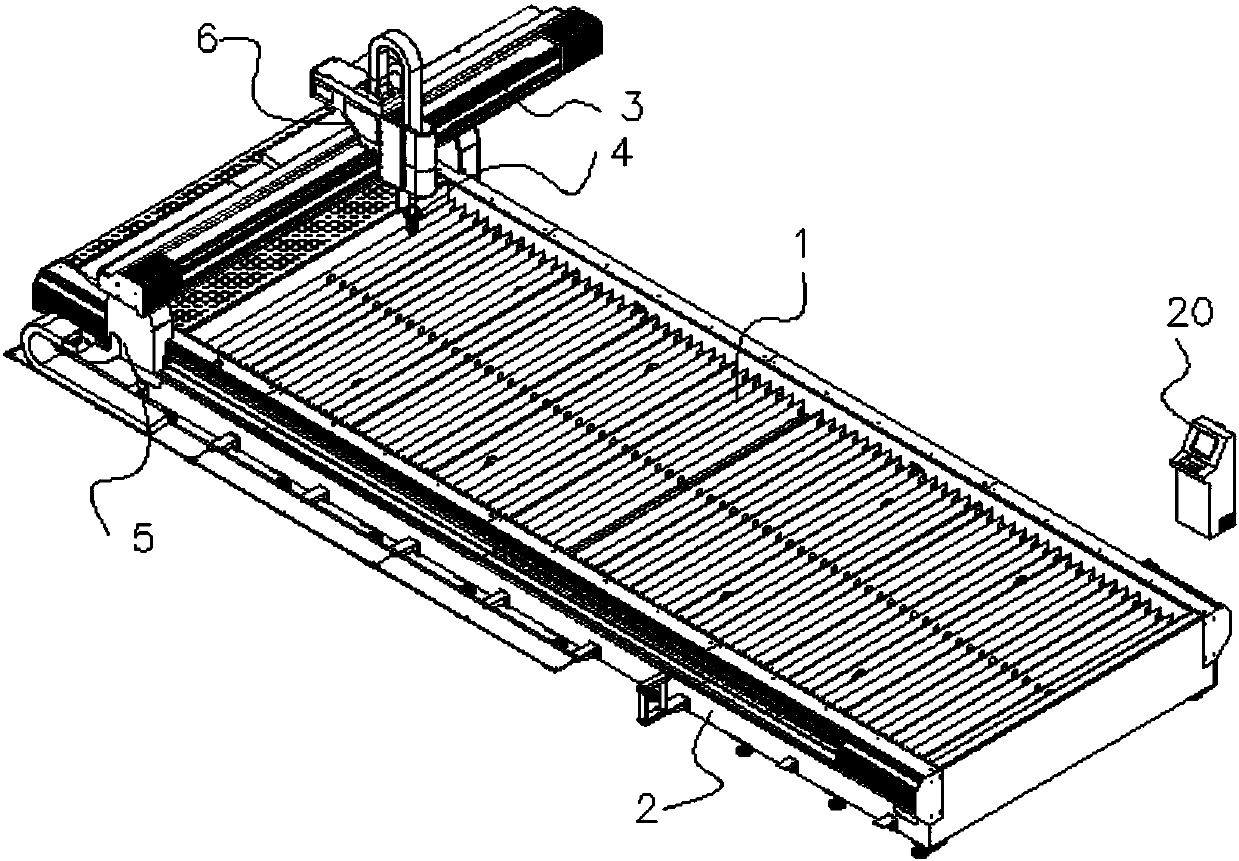

[0048] Embodiment 1: a kind of desktop numerical control cutting machine, such as Figure 1-1 to Figure 10 As shown, the length direction of the cutting machine is defined as longitudinal, including workbench 1, frame 2, beam 3 and cutting torch 4, the frame is located on both sides of the longitudinal direction of the workbench, and the beam is located on the Above the workbench, the cutting torch is connected to the crossbeam, including a longitudinal transmission device 5 for driving the crossbeam to move longitudinally, a transverse transmission device 6 for driving the cutting torch to move laterally, and a horizontal transmission device for driving the cutting torch to move horizontally. The lifting device 7 that moves up and down and the ventilation and dust removal device for ventilation and dust removal;

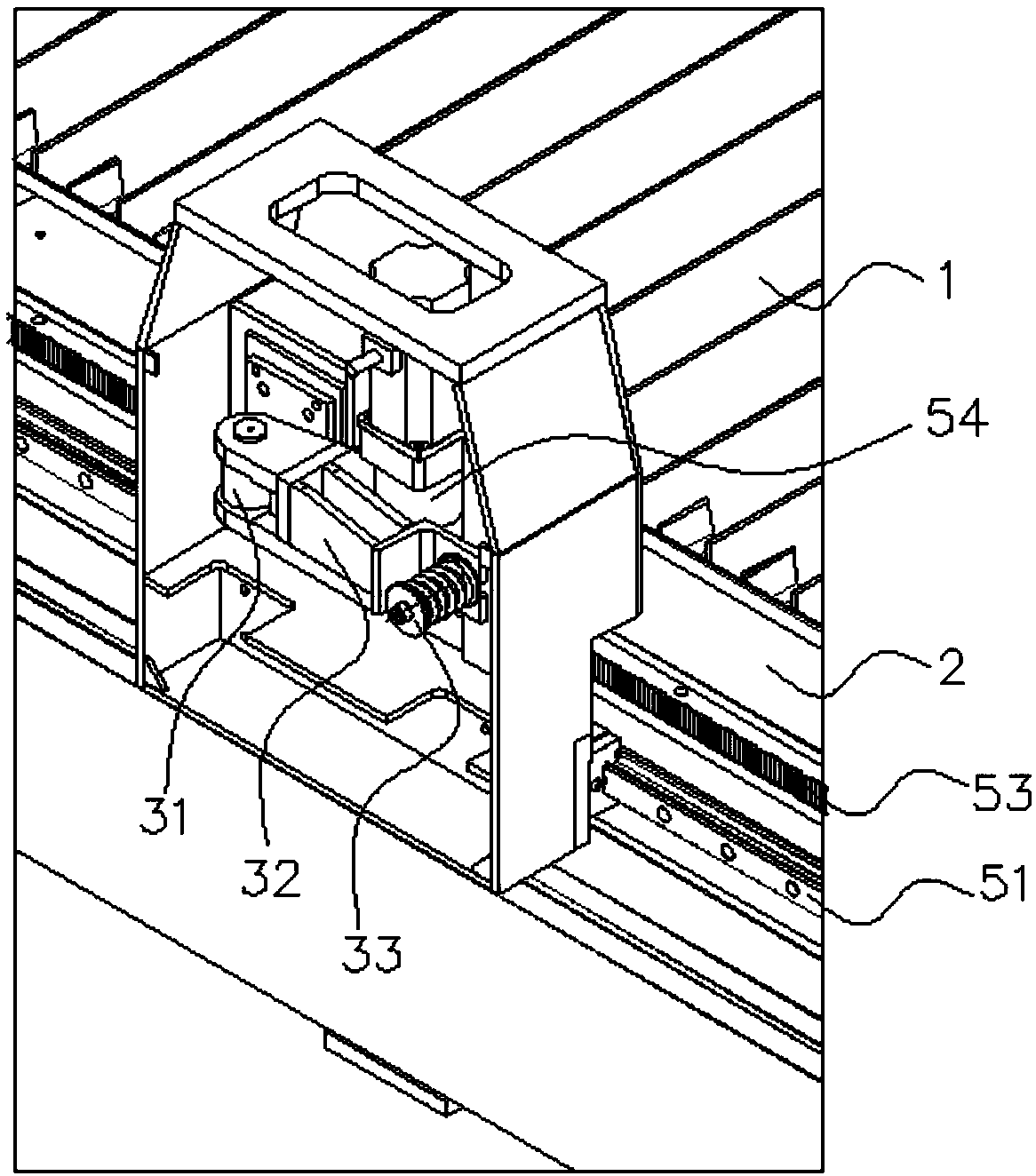

[0049] The longitudinal transmission device 5 includes a first track 51, a first gear 52, a first rack 53 and a first motor 54, the first track and the first rack a...

Embodiment 2

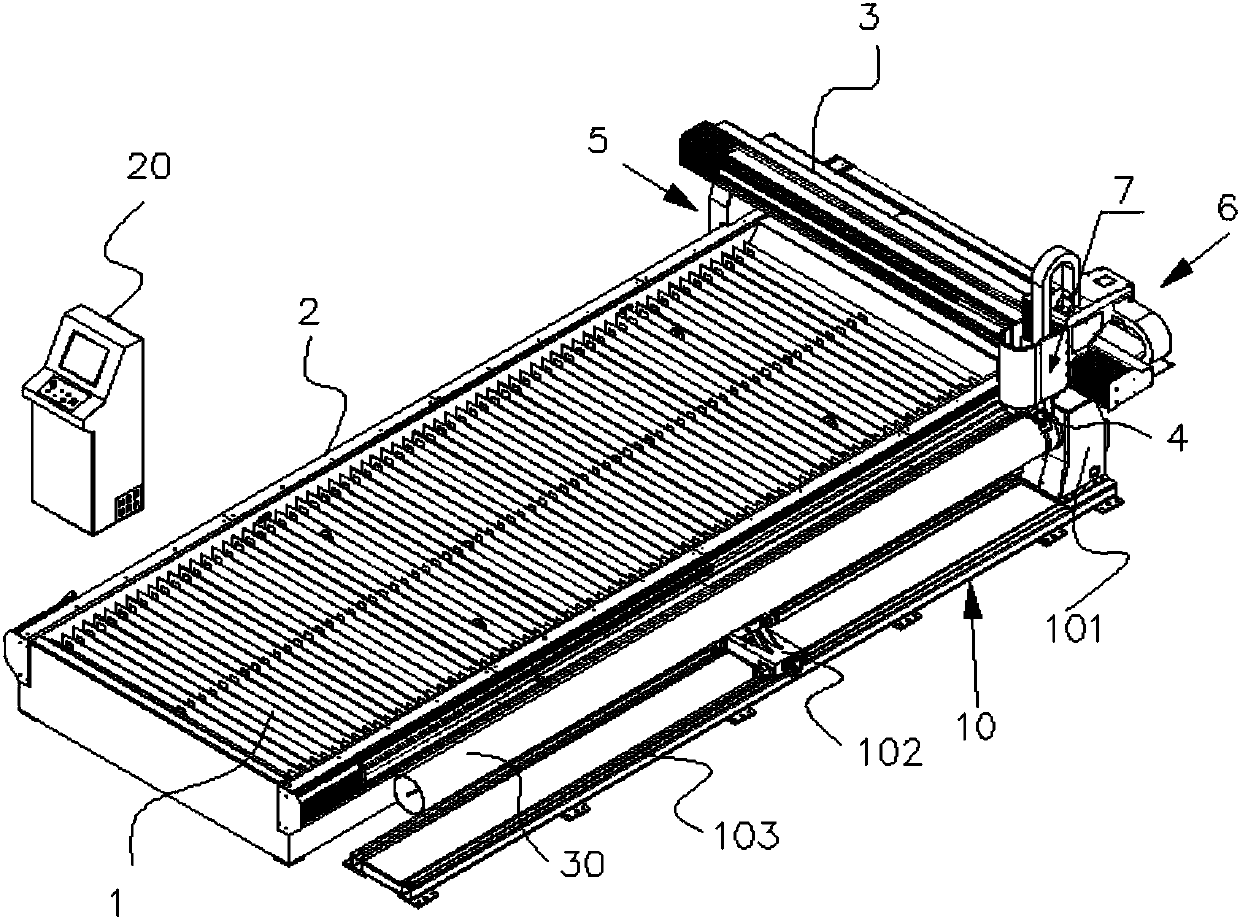

[0069] Embodiment 2: a kind of desktop numerical control cutting machine, such as Figure 1-2 Shown, similar to embodiment 1 structure, difference is:

[0070] The cutting machine also includes a pipe cutting unit 10, the pipe cutting unit is located on the side of the workbench and parallel to the workbench, the pipe cutting unit includes a pipe positioning seat 101, a pipe moving frame 102 and a third guide rail 103, the pipe positioning seat is fixed on one end of the third guide rail, the pipe moving frame is located on the third guide rail and can move along the third guide rail, the pipe 30 is located on the pipe moving frame and the pipe One end is limited by the pipe positioning seat.

[0071] Working principle and working process of the present invention are as follows:

[0072] Place the workpiece to be cut on the workbench, start the cutting machine, under the control of the control system, the first motor of the longitudinal transmission device drives the beam th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com