Preparation method of sapo-34/sapo-5 composite molecular sieve

A technology of SAPO-34 and SAPO-5, which is applied in the field of molecular sieve synthesis, can solve the problems of poor product repeatability and complicated steps, and achieve the effect of long butene selectivity, strong repeatability and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

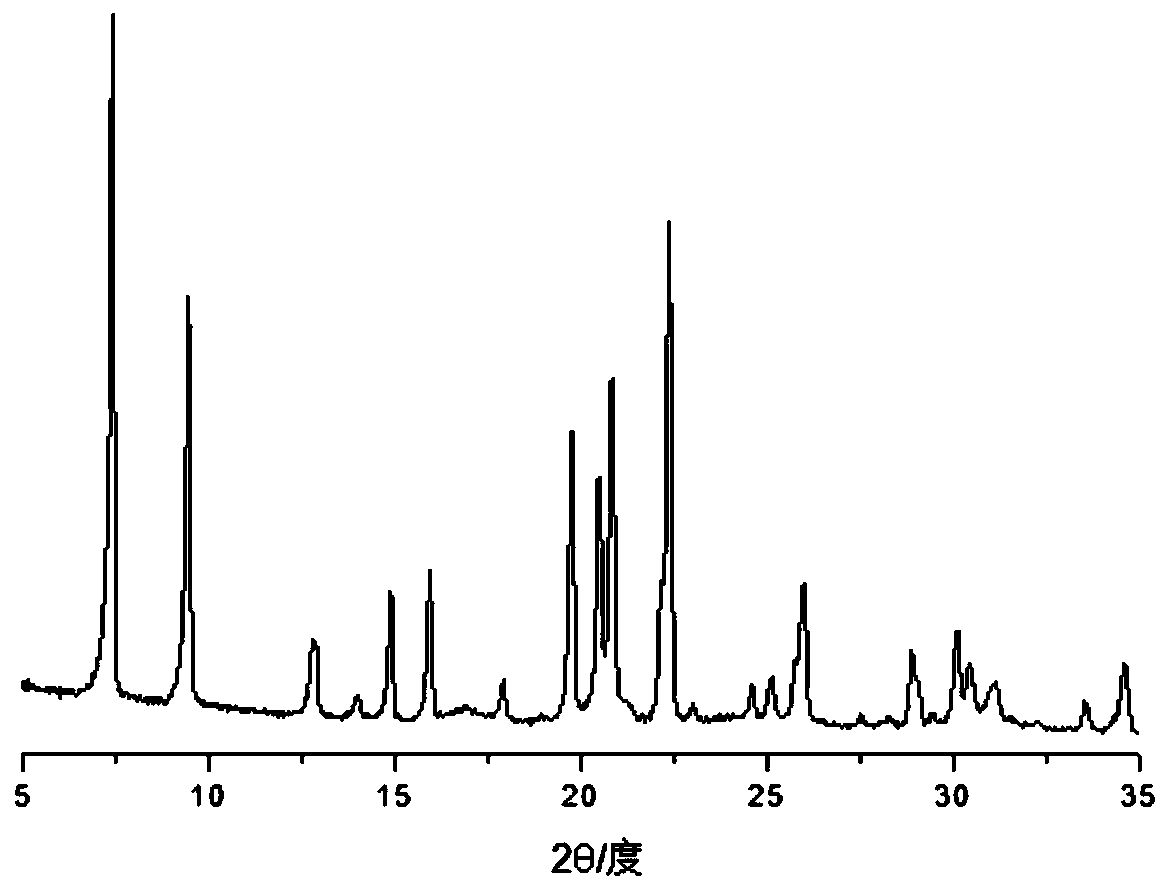

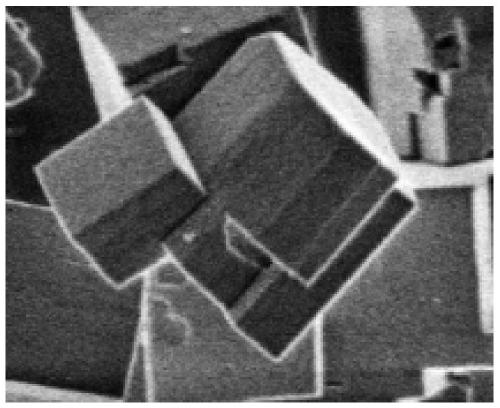

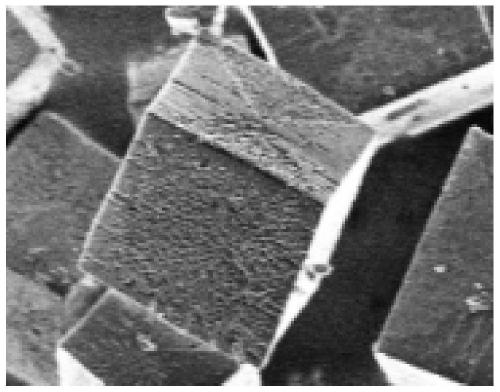

Image

Examples

Embodiment 1

[0026] The preparation method of the present embodiment SAPO-34 / SAPO-5 composite silicoaluminophosphate molecular sieve comprises the following steps:

[0027] Step 1, 0.12mol phosphoric acid (in P 2 o 5 In terms of), 0.12mol silica sol (as SiO 2 After mixing with 1mol deionized water evenly, add slowly while stirring (adding in 30 times, adding in 80 minutes) 0.11mol pseudo-boehmite (in the form of Al 2 o 3 After stirring for 30 minutes, 0.36 mol of triethylamine was added, and the first gel mixture was obtained after stirring evenly. Then, the first gel mixture was placed in a crystallization kettle, and the temperature was kept at 200° C. for 22 hours for the second gel mixture. A hydrothermal crystallization treatment, cooling to obtain the first crystallization liquid after crystallization;

[0028] Step 2. Slowly add (add in 30 times, finish adding in 60 minutes) 0.014mol pseudo-boehmite (with Al 2 o 3 meter), continue to stir for 30min and then add 0.013mol phosph...

Embodiment 2

[0032] The preparation method of the present embodiment SAPO-34 / SAPO-5 composite silicoaluminophosphate molecular sieve comprises the following steps:

[0033] Step 1, 0.18mol phosphoric acid (in P 2 o 5 In terms of), 0.17mol ethyl orthosilicate (as SiO 2 After mixing evenly with 1mol deionized water, add slowly while stirring (adding in 25 times, adding in 80min) 0.15mol pseudo-boehmite (in the form of Al 2 o 3 After stirring for 30 minutes, 0.30 mol of morpholine was added, and the first gel mixture was obtained after stirring evenly. Then, the first gel mixture was placed in a crystallization kettle, and the temperature was kept at 220° C. for 18 hours to carry out the first gel mixture. Hydrothermal crystallization treatment, cooling to obtain the first crystallization liquid after crystallization;

[0034] Step 2. Slowly add (add in 25 times, finish adding in 60 minutes) 0.01mol pseudo-boehmite (with Al 2 o 3 meter), continue to stir for 30min and then add 0.01mol p...

Embodiment 3

[0037] The preparation method of the present embodiment SAPO-34 / SAPO-5 composite silicoaluminophosphate molecular sieve comprises the following steps:

[0038] Step 1, 0.15mol phosphoric acid (in P 2 o 5 In terms of), 0.14mol silica sol (as SiO 2 After mixing evenly with 1mol deionized water, add slowly while stirring (adding in 35 times, adding in 80 minutes) 0.13mol pseudo-boehmite (in the form of Al 2 o 3 After stirring for 30 minutes, 0.24 mol of triethylamine was added, and the first gel mixture was obtained after stirring evenly. Then, the first gel mixture was placed in a crystallization kettle, and the temperature was kept at 180° C. for 24 hours to carry out the second gel mixture. A hydrothermal crystallization treatment, cooling to obtain the first crystallization liquid after crystallization;

[0039] Step 2. Slowly add (add in 35 times, finish adding in 60 minutes) 0.012mol pseudo-boehmite (with Al 2 o 3 meter), continue to stir for 30min and then add 0.012m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com