Preparation method of a silver-loaded polymer catalyst with switchable selectivity

A catalyst and polymer technology, which is applied in the preparation of organic compounds, aminohydroxyl compounds, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of the inability to realize the preparation of selective switchable polymer catalysts, etc. Achieve the effects of large-scale industrial production, easy large-scale industrial production, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

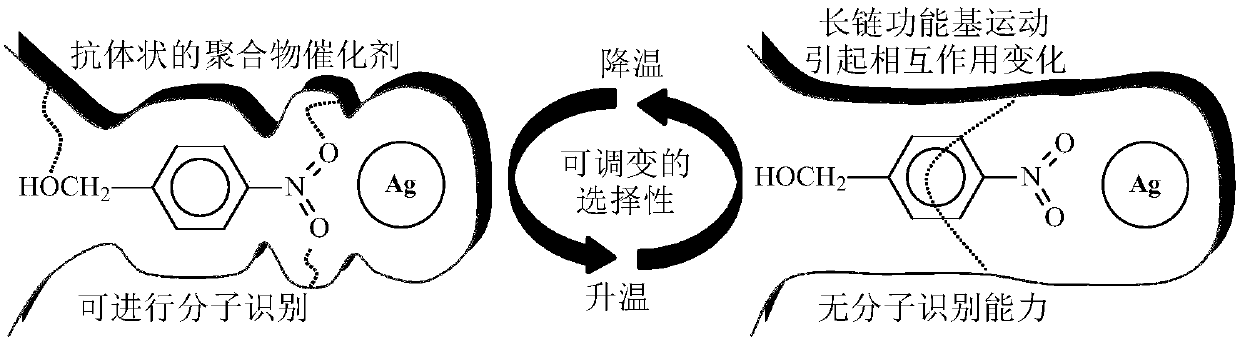

[0034] For the technical principle of polymer catalyst preparation, see figure 1 The binary functional monomer system used to construct two different functions of the polymer, namely the molecular recognition framework and the side chain structure of the movable functional group, is 10-hydroxy-2-decenoic acid and acrylic acid in a molar ratio of 1:4. The substrate p-nitrobenzyl alcohol (4mmol) and the silver precursor silver nitrate (2mmol) were first dissolved in 20mL dimethyl sulfoxide for complexation to form a template molecule, and the functional monomer 10-hydroxyl-2-decenoic acid ( 6mmol) and acrylic acid (24mmol), cross-linking agent N, N methylenebisacrylamide (3mmol) and initiator azobisisobutyronitrile (0.1g), then nitrogen deoxygenation (8 minutes) in the solution, sealed Afterwards, it was placed under an ultraviolet lamp to irradiate to initiate polymerization (24 hours) to form a catalyst precursor. The Ag ions in the catalyst precursor are reduced by an excess...

Embodiment 2

[0041] The operation was the same as in Example 1, except that the long-chain functional monomer was changed to 2-nonenoic acid (6 mmol), and the other operations were completely the same as in Example 1 to obtain a silver-loaded polymer catalyst AgPR-ST with a transition point of about 38°C. Under the same catalytic test conditions as in Example 1, 30°C and 45°C above and below the transition point were selected for comparative measurement, and the results are shown in Figure 8 . At 30°C, AgPR-ST, similar to AgPR-T, exhibited a highly selective catalytic effect on the specific substrate p-nitrobenzyl alcohol; in contrast, at 45°C, AgPR-ST became similar to AgPR-T. AgPR-S is similar in that it exhibits no selectivity for p-nitrobenzyl alcohol and its analog o-nitrobenzyl alcohol. The as-prepared AgPR-ST catalyst also exhibits the characteristics of selectively tunable catalysis.

Embodiment 3

[0043] The operation was the same as in Example 1, except that the long-chain functional monomer was changed to octadecenoic acid (3 mmol), and the other operations were completely the same as in Example 1 to obtain a silver-loaded polymer catalyst AgPR-ST with a transition point of about 34°C. Under the same catalytic test conditions as in Example 1, 28°C and 40°C above and below the transition point were selected for comparison and measurement, the results are shown in Figure 9 . At 28°C, AgPR-ST, similar to AgPR-T, exhibited a highly selective catalytic effect on the specific substrate p-nitrobenzyl alcohol; in contrast, at 40°C, AgPR-ST became similar to AgPR-T. AgPR-S is similar in that it exhibits no selectivity for p-nitrobenzyl alcohol and its analog o-nitrobenzyl alcohol. The as-prepared AgPR-ST catalyst also exhibits the characteristics of selectively tunable catalysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com