High-hardness epoxy-modified polyurethane composite material and preparation method thereof

An epoxy modification and composite material technology, applied in the field of organic polymer elastic materials and their preparation, can solve the problems of insignificant increase in the hardness value of polyurethane materials, inability to meet use requirements, difficult operation control, etc., and achieve excellent catalytic effect, The effect of expanding the scope of application and adjustable response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

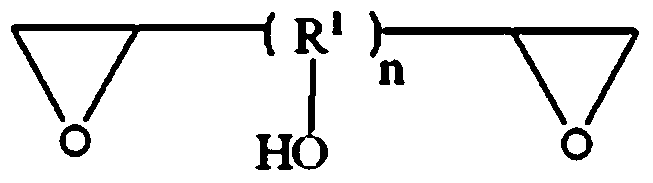

[0039] A high-hardness epoxy-modified polyurethane composite material of the present invention, the Shore D hardness of the composite material is ≥70, and the epoxy-modified polyurethane composite material is made by using a prepolymer method to add the A component and the B component to It is prepared after mixing and reaction in a vacuumable airtight container; component A is a mixture of isocyanate-terminated prepolymer and epoxy resin; component B is a mixture of chain extender and catalyst.

[0040] The method for preparing the above-mentioned high-hardness epoxy-modified polyurethane composite material in this embodiment specifically includes the following steps:

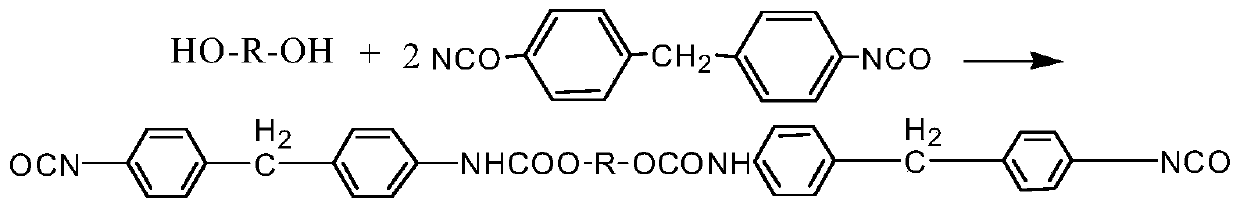

[0041] 1. Preparation of isocyanate-terminated prepolymer

[0042] Polyether polyol and polyester polyol are polymerized with polyisocyanate to prepare isocyanate-terminated prepolymer, which specifically includes the following steps: In parts by mass, 24.1 g of polytetrahydrofuran ether glycol (PTMG, equivalent 1000...

Embodiment 2

[0063] A high-hardness epoxy-modified polyurethane composite material of the present invention, the Shore D hardness of the composite material is ≥70, and the epoxy-modified polyurethane composite material is made by using a prepolymer method to add the A component and the B component to It is prepared after mixing and reaction in a vacuumable airtight container; component A is a mixture of isocyanate-terminated prepolymer and epoxy resin; component B is a mixture of chain extender and catalyst.

[0064] The method for preparing the above-mentioned high-hardness epoxy-modified polyurethane composite material in this embodiment specifically includes the following steps:

[0065] 1. Preparation of isocyanate-terminated prepolymer

[0066] Polyester polyol and polyisocyanate polymerization reaction is used to prepare isocyanate-terminated prepolymer, specifically including the following steps: in parts by mass, 60.5g polyethylene adipate diol (PEA, equivalent of 500, functionality 2) A...

Embodiment 3

[0082] A high-hardness epoxy-modified polyurethane composite material of the present invention, the Shore D hardness of the composite material is ≥70, and the epoxy-modified polyurethane composite material is made by using a prepolymer method to add the A component and the B component to It is prepared after mixing and reaction in a vacuumable airtight container; component A is a mixture of isocyanate-terminated prepolymer and epoxy resin; component B is a mixture of chain extender and catalyst.

[0083] The method for preparing the above-mentioned high-hardness epoxy-modified polyurethane composite material in this embodiment specifically includes the following steps:

[0084] 1. Preparation of isocyanate-terminated prepolymer

[0085] The polymerization reaction of polyether polyol and polyisocyanate to prepare isocyanate-terminated prepolymer specifically includes the following steps: In parts by mass, 44.28 g of polytetrahydrofuran ether glycol (PTMG, equivalent weight 500, funct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com