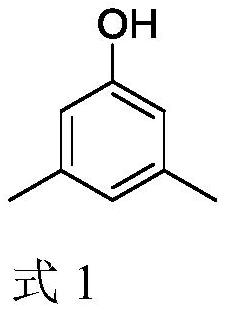

The preparation method of 3,5-dimethylphenol

A technology of dimethylphenol and isophorone, which is applied in the field of preparation of 3,5-dimethylphenol, can solve the problems of high equipment requirements, high price and low selectivity, avoid side reactions and reduce consumption , improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

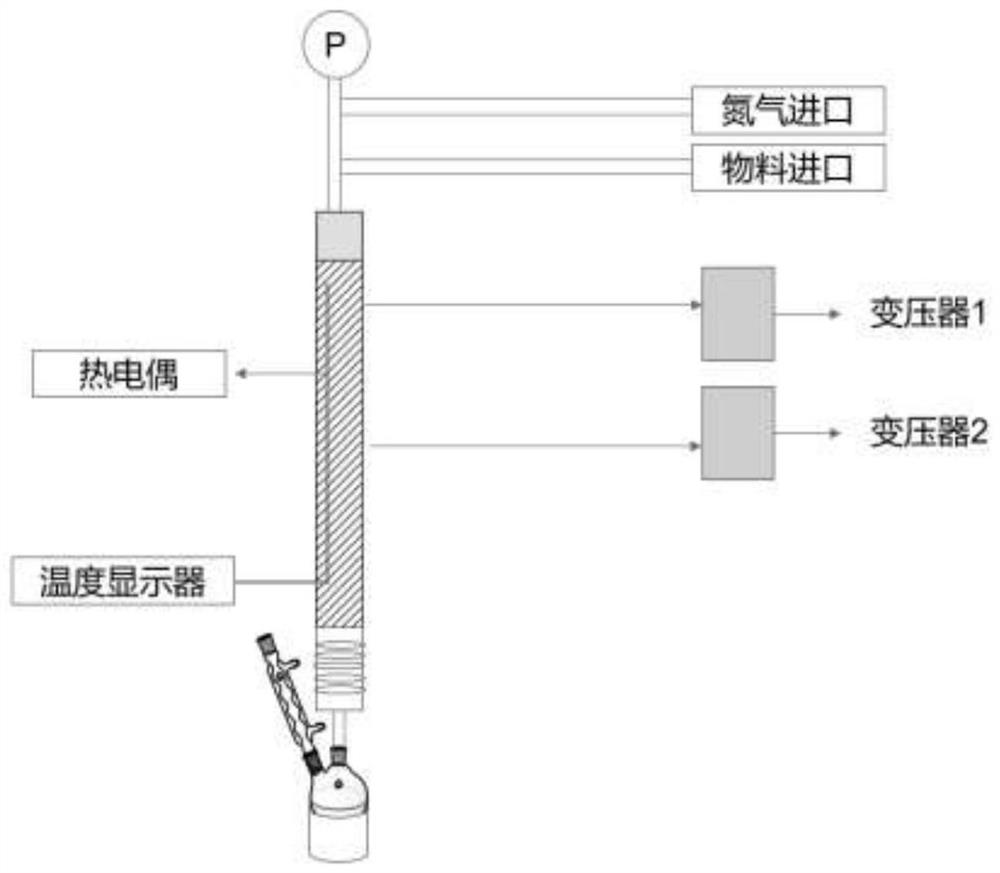

Method used

Image

Examples

Embodiment 1

[0029] Example 1, a method for preparing 3,5-dimethylphenol, the following steps are performed in turn:

[0030] 1), molecular sieve water removal:

[0031] Weigh 20g 3A molecular sieve, activate at 400 °C for 8h, cool to about 150 °C, add to 200 g of isophorone, seal, stand for 24 h; isophorone after removal of water.

[0032] Using the Karl Fischer moisture analyzer, the following results were measured: before water removal, the water content of isophorone was about 1.5%, and after water removal, the water content of isophorone was 0.2%. The above % is quality.

[0033] 2), weigh 100g of isofolone after water removal, add 1g of dibromoethane, evenly mixed, to obtain a mixture of raw materials;

[0034]The tube reactor is heated up to 500 ° C, the raw material mixture is pumped into the tubular reactor under the protection of nitrogen, the feed rate is 1.1ml / min (i.e., the residence time of the raw material mixture in the tubular reactor is 44s), the reaction is carried out und...

Embodiment 2~ Embodiment 7

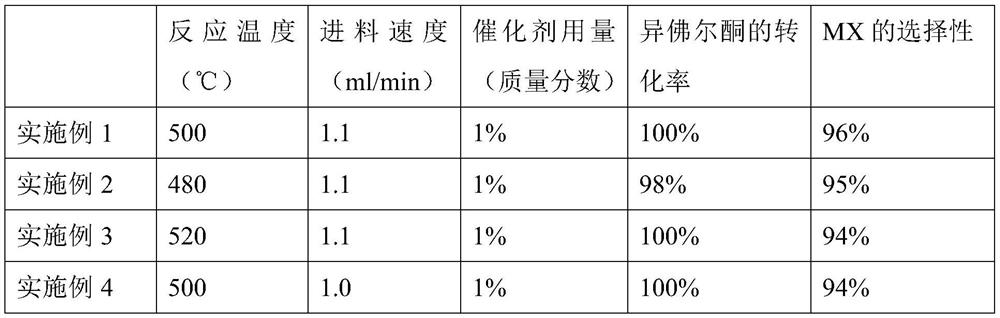

[0038] Change the catalyst dosage in Example 1, feed rate and reaction temperature, the rest is equivalent to Example 1, respectively, to obtain the following Example 2 to 7, the conversion of the resulting isophorone and the selectivity of MX is shown in Table 1 below.

[0039] Table 1

[0040]

[0041]

[0042] Illustrate:

[0043] The feeding speed is 1.0ml / min, and the residence time of the corresponding material in the tubular reactor is 48s;

[0044] The feed rate is 1.2ml / min, and the residence time of the corresponding material in the tubular reactor is 40s.

Embodiment 8-9

[0045] Example 8-9, step 1) is changed to: respectively, to the raw materials to add anhydrous sodium sulfate, anhydrous magnesium sulfate solid, the amount added is 10% of the quality of isophorone, sealed, standing for 24h, the rest is equivalent to Example 1, the result is as follows Table 2:

[0046] Table 2

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com