C60 fullerene peracetylated glucose derivative and application of C60 fullerene peracetylated glucose derivative as lithium battery cathode material

A technology of glucose derivatives and fullerene peracetyl, which can be used in the preparation of sugar derivatives, sugar derivatives, and sugar derivatives, etc., can solve the problems of low specific capacity of secondary lithium battery specific energy positive electrode materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

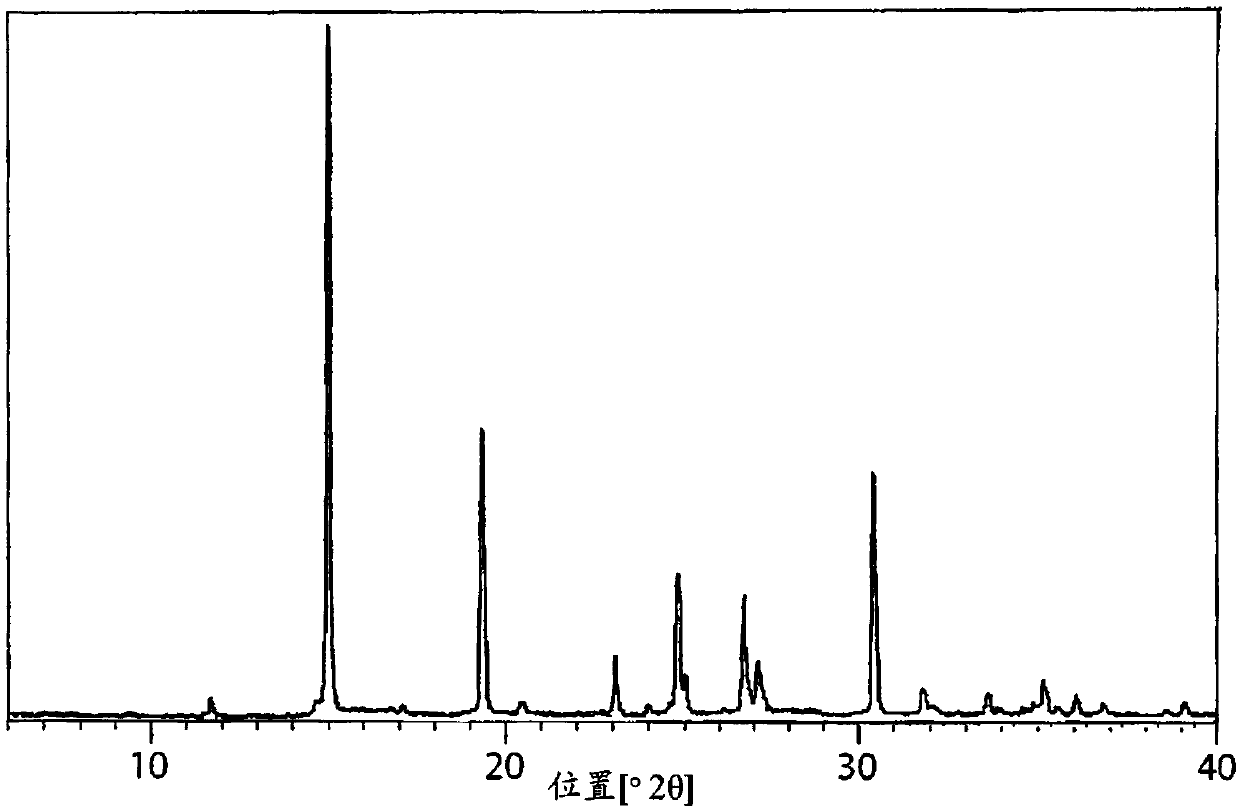

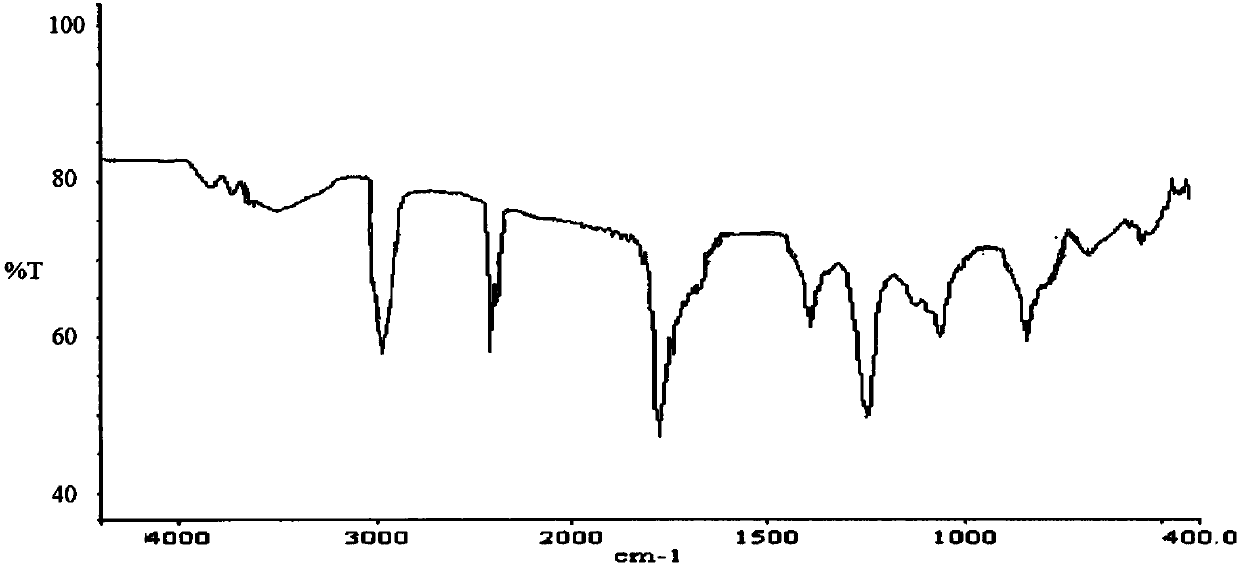

[0017] Weigh C60 fullerene (1mmol), formula II compound (1mmol, CAS registration number: 191668-88-9) and dissolve in chlorobenzene (15mL), heat to 75-80°C for 6 hours, continue to heat to reflux After 12 hours of temperature reaction, after concentration under reduced pressure, silica gel column chromatography (stationary phase: 200-300 mesh silica gel, mobile phase: toluene / acetone = 10:1-10:2) gave a light brown solid (536 mg, yield About 48%), namely the compound of formula I, by mass spectrometry (ESI-MS (m / z): 1116.1 [M+H] + ), X-ray powder diffraction (XRPD) ( figure 1 ), infrared ( figure 2 ) and other parameters.

Embodiment 2

[0019] Weigh C60 fullerene (2mmol), formula II compound (1mmol, CAS registration number: 191668-88-9) and dissolve in DMF (20mL), heat to 75-80°C for 10 hours, continue to heat to reflux temperature After reacting for 8 hours and concentrating under reduced pressure, silica gel column chromatography (stationary phase: 200-300 mesh silica gel, mobile phase: toluene / acetone=10:1-10:2) gave a light brown solid (569 mg, yield approx. 51%), which is the compound of formula I, and the structural characterization data is consistent with that of Example 1.

Embodiment 3

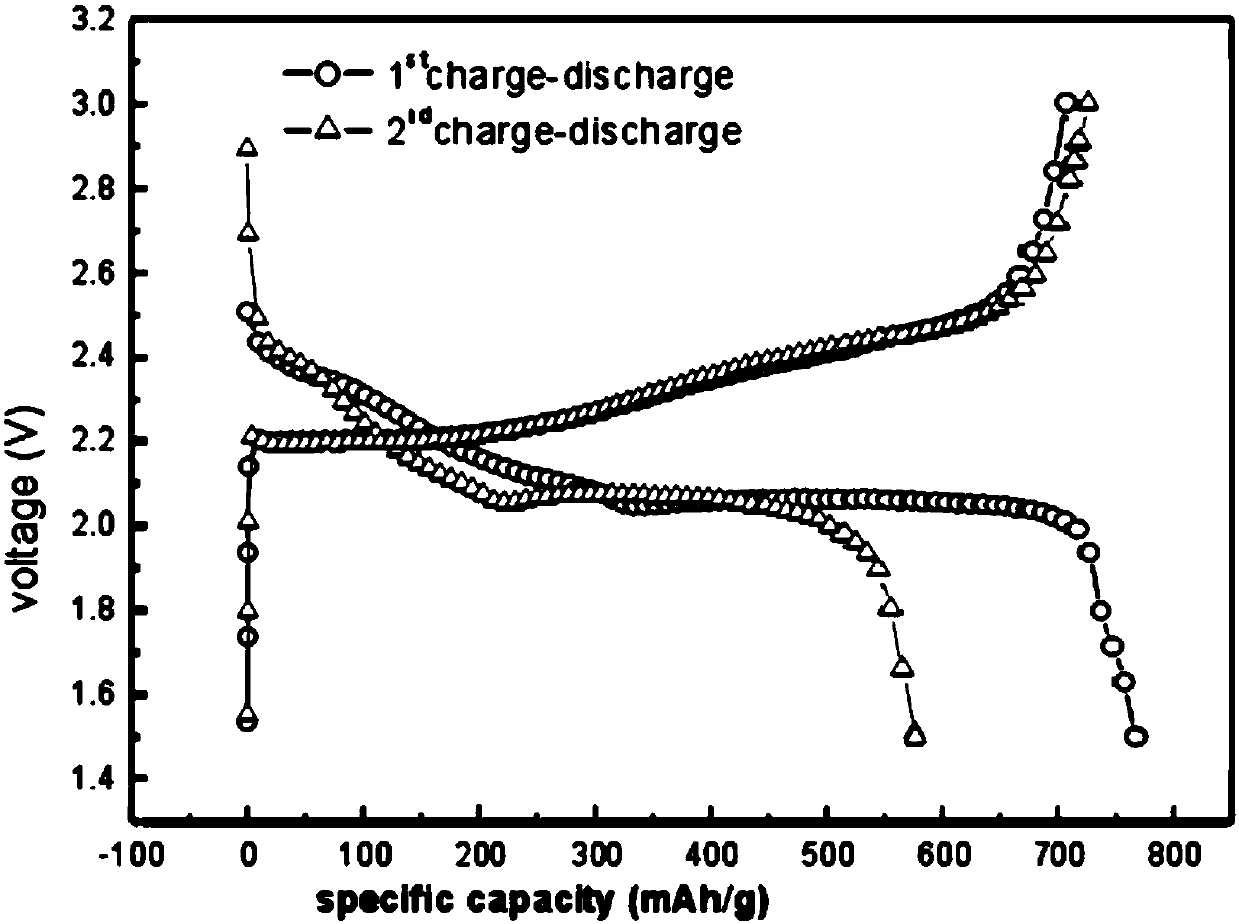

[0021] A simulated battery was assembled with the compound of formula I of the present invention as the positive electrode active material and metal lithium, and the electrochemical performance test was carried out.

[0022] The present invention adopts the coating method to prepare the composite pole piece, mixes the compound of formula I, the conductive agent acetylene black, and the adhesive PEO according to the mass ratio of 60%, 30%, and 10%, and grinds them uniformly, then mixes them with a mixed solvent of water and n-propanol (volume ratio 1:4) into a paste, spread evenly on the current collector, dry at room temperature for 24 hours, cut into 1×1cm 2 The pole pieces were vacuum-dried at 60°C for 8 hours for later use.

[0023] The simulated battery adopts a two-electrode system. The composite pole piece prepared by the above method is used as the positive electrode, and the lithium foil is used as the negative electrode. 1MLi CF 3 SO 3 The dioxolane + diglyme + ethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com