Calcium carbonate-based fluorescent material and preparation method of material

A fluorescent material, calcium carbonate-based technology, applied in the field of fluorescent materials, can solve the problems of weak luminescence of rare earth ions, etc., and achieve the effect of simple and easy method, high yield, and saving rare earth resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

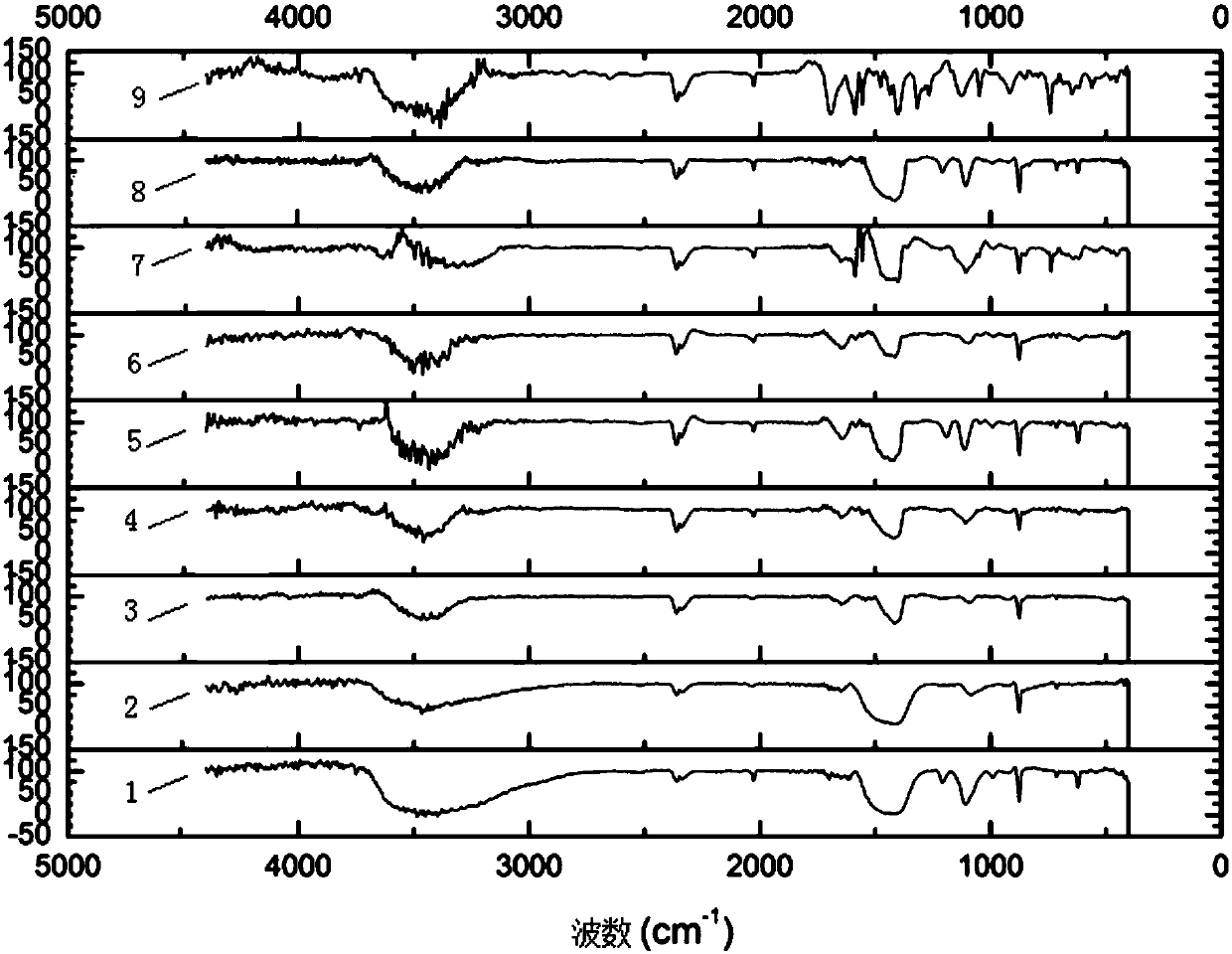

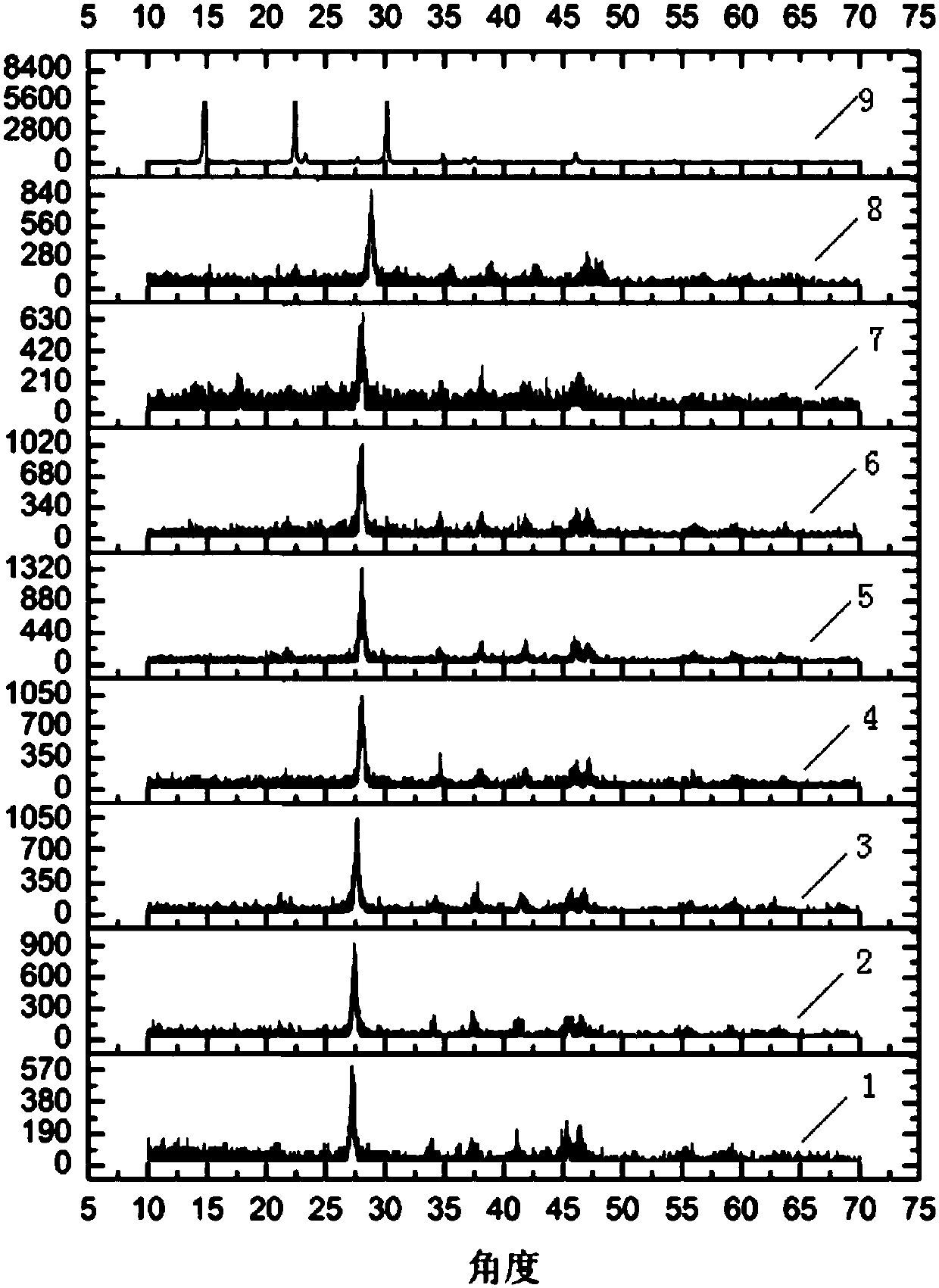

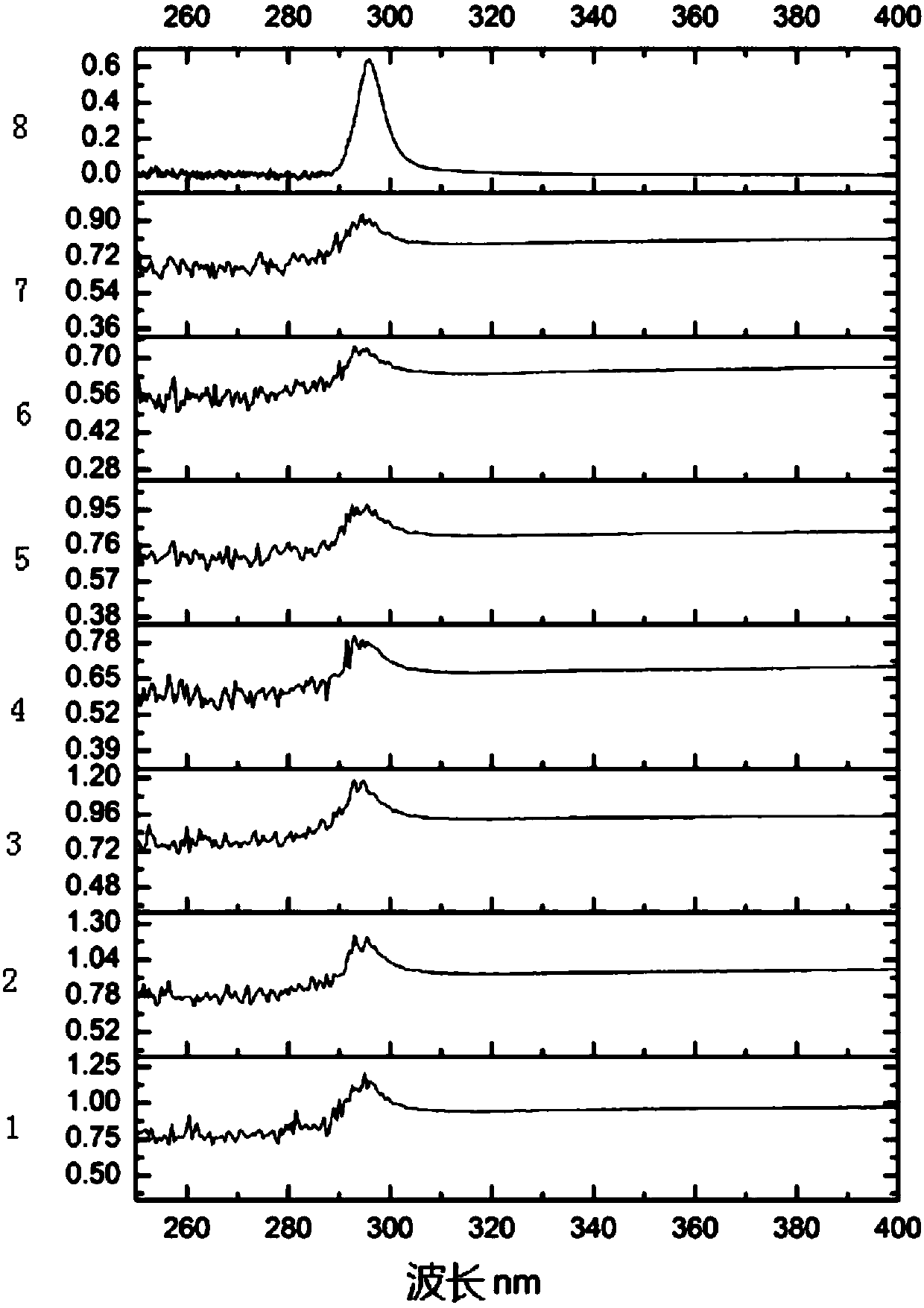

Embodiment 1

[0092] (1) Weigh 0.3000g of the calcium carbonate powder prepared in (1) and place it in a 50mL small beaker A, add 30mL of absolute ethanol; then weigh 1.5mmol 2-chlorobenzoic acid and 0.5mmol prepared in (2) respectively Place terbium chloride hexahydrate in a 50mL small beaker B, add 10mL of absolute ethanol, and ultrasonically vibrate the two small beakers A and B for 30 minutes to make them evenly dispersed;

[0093] (2) Control the temperature of the digital display heat-collecting magnetic stirrer to 18°C, then place the solutions in the uniformly heated A and B beakers in the three-necked flask for reaction, add magnets to stir, and make it fully react. When the reaction time reaches One hour, stop heating and stirring,

[0094] (3) Take out the three-necked flask and wipe it clean, then use a Buchner funnel to suction filter the liquid in the flask, repeat 2 to 3 times to clarify the filtrate, remove the filter paper, dry it in a vacuum drying oven at 80°C for 12 hour...

Embodiment 2

[0096] (1) Weigh 0.1000g of calcium carbonate powder prepared in (1) and place it in a 50mL small beaker A, add 30mL of absolute ethanol; then weigh 1.5mmol 2-chlorobenzoic acid and 0.5mmol prepared in (2) respectively Place terbium chloride hexahydrate in a 50mL small beaker B, add 10mL of absolute ethanol, and ultrasonically vibrate the two small beakers A and B for 30 minutes to make them evenly dispersed;

[0097] (2) Control the temperature of the digital display heat-collecting magnetic stirrer to 28°C, then place the solutions in the evenly heated A and B beakers in the three-necked flask for reaction, add magnets to stir, and make it fully react. When the reaction time reaches One hour, stop heating and stirring,

[0098] (3) Take out the three-necked flask and wipe it clean, then use a Buchner funnel to suction filter the liquid in the flask, repeat 2 to 3 times to clarify the filtrate, remove the filter paper, dry it in a vacuum drying oven at 80°C for 12 hours, take...

Embodiment 3

[0100] (1) Weigh 1.0g of the calcium carbonate powder prepared in (1) and place it in a 50mL small beaker A, add 30mL of absolute ethanol; then weigh 1.5mmol 2-chlorobenzoic acid and 0.5mmol prepared in (2) respectively Place terbium chloride hexahydrate in a 50mL small beaker B, add 10mL of absolute ethanol, and ultrasonically vibrate the two small beakers A and B for 30 minutes to make them evenly dispersed;

[0101] (2) Control the temperature of the digital display heat-collecting magnetic stirrer to 38°C, then place the solutions in the evenly heated A and B beakers in the three-necked flask for reaction, add magnets to stir, and make it fully react. When the reaction time reaches One hour, stop heating and stirring,

[0102] (3) Take out the three-necked flask and wipe it clean, then use a Buchner funnel to suction filter the liquid in the flask, repeat 2 to 3 times to clarify the filtrate, remove the filter paper, dry it in a vacuum drying oven at 80°C for 12 hours, tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fluorescence lifetime | aaaaa | aaaaa |

| The fluorescence intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com