Current collector for lithium-ion battery, preparation method of current collector, pole piece for lithium-ion battery and lithium-ion battery

A lithium-ion battery and current collector technology, which is applied in electrode carriers/current collectors, electrode manufacturing, secondary batteries, etc., can solve problems such as temperature increase, lithium-ion battery safety performance degradation, and lithium-ion battery thermal runaway reaction, etc. Achieve the effect of improving safety, slowing down exothermic reaction, and avoiding short-circuit discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

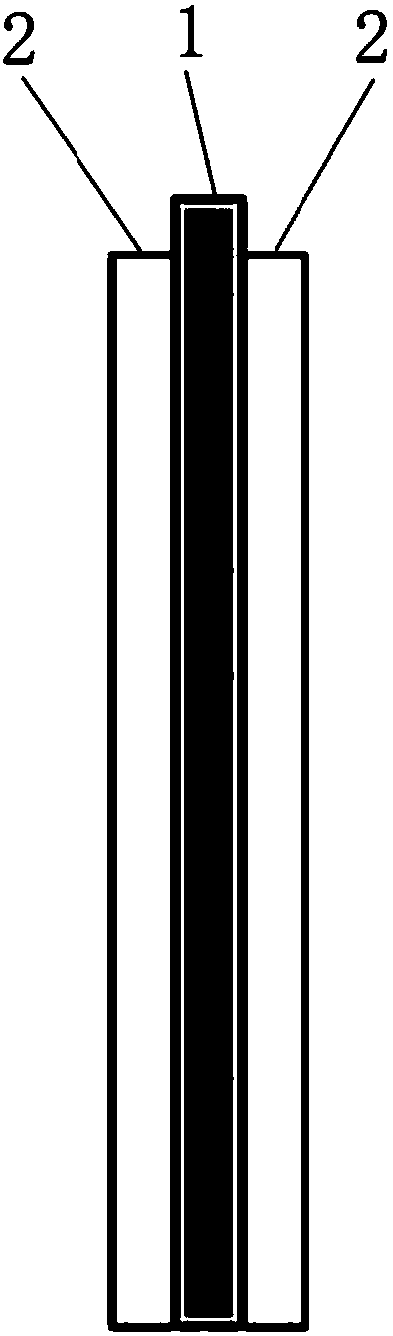

[0040] The lithium ion battery current collector of the present embodiment, such as figure 1 As shown, an aluminum foil 1 with a thickness of 18 μm is included, and a PTC layer 2 is attached to both sides of the aluminum foil 1; the thickness of the PTC layer 2 is 2 μm (single layer thickness).

[0041] The PTC layer 2 contains 98% (mass percent) positive temperature coefficient material, and the balance is PVDF binder; the positive temperature coefficient material is strontium titanate sintered body doped with metal oxide, and the metal oxide Neodymium oxide (Nd 2 o 3 ), the doping amount of metal oxide is 0.1%.

[0042] The preparation method of the lithium ion battery current collector of the present embodiment comprises the following steps:

[0043] 1) Dissolve PVDF binder in N-methylpyrrolidone, then add positive temperature coefficient material powder, the mass ratio of positive temperature coefficient material powder to binder is 98:2, and disperse evenly to make the...

Embodiment 2

[0057] The current collector for lithium-ion batteries of this embodiment (same structure as in Embodiment 1) includes an aluminum foil with a thickness of 18 μm, and a PTC layer is attached to both sides of the aluminum foil; the thickness of the PTC layer is 10 μm (single-layer thickness).

[0058] The PTC layer 2 contains 98% (mass percent) positive temperature coefficient material, and the balance is PVDF binder; the positive temperature coefficient material is a lead titanate sintered body doped with metal oxide, and the metal oxide Nd 2 o 3 and La 2 o 3 , the doping amount of metal oxide is 0.1%.

[0059] The preparation method of the lithium ion battery current collector of the present embodiment comprises the following steps:

[0060] 1) Dissolve PVDF binder in N-methylpyrrolidone, then add positive temperature coefficient material powder, the mass ratio of positive temperature coefficient material powder to binder is 98:2, and disperse evenly to make the solid con...

experiment example

[0074] 1. Make the battery

[0075] 1) Make positive electrode

[0076] Dissolve 2 parts by weight of PVDF (polyvinylidene fluoride) in NMP (N-methylpyrrolidone), prepare a binder slurry, and uniformly mix 1.5 parts by weight of conductive graphite in the binder, 100 parts by weight of LiNi 0.5 co 0.2 mn 0.3 (Positive electrode active material) mixed with conductive paste. Apply the obtained positive electrode slurry on both surfaces of the above-mentioned current collector, that is, the prepared PTC-coated aluminum foil, then dry it, and then roll it and die-cut it, so that the desired positive electrode sheet is obtained. .

[0077] 2) Make the negative electrode

[0078] Dissolve 1.5 parts by weight of CMC (sodium carboxymethylcellulose) in ionized water to prepare a binder slurry, uniformly mix 1.5 parts by weight of conductive graphite in the binder, and mix 100 parts by weight of The negative electrode active material was mixed with the conductive paste, and 2 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com