A positive temperature coefficient thermosensitive material and its preparation method

A technology of positive temperature coefficient and heat-sensitive material, applied in resistors with positive temperature coefficient, electrical components, electrochemical generators, etc. Exothermic reaction, avoid short-circuit discharge, improve the effect of anti-overcharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

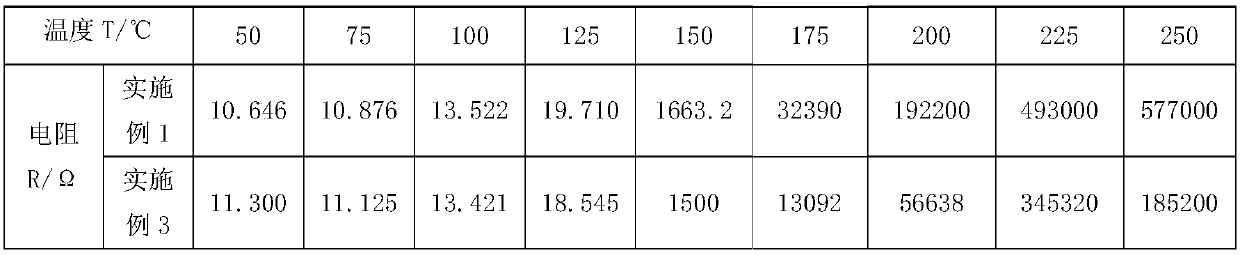

Embodiment 1

[0033] The positive temperature coefficient heat-sensitive material of this embodiment is made of the following raw materials: strontium source, titanium source, manganese source, metal oxide, sintering aid; the above-mentioned strontium source, titanium source, manganese source, metal oxide, sintering aid The molar ratio is 0.9915:1.0095:0.0004:0.002:0.001; the strontium source is strontium titanate, the titanium source is titanium dioxide, and the manganese source is Mn(NO 3 ) 2 , the metal oxide is Nd with a molar ratio of 1:3 2 o 3 and La 2 o 3 , The sintering aid is a mixture of alumina, silicon dioxide, and zirconium dioxide in a molar ratio of 0.03:0.03:0.62.

[0034] The preparation method of the positive temperature coefficient thermosensitive material of the present embodiment comprises the following steps:

[0035] 1) Mixing

[0036] Strontium titanate, titanium dioxide, Nd with a molar ratio of 0.9915:1.0095:0.0005:0.0015 2 o 3 , La 2 o 3 Put it into a ba...

Embodiment 2

[0043] The positive temperature coefficient heat-sensitive material of this embodiment is made of the following raw materials: strontium source, titanium source, manganese source, metal oxide, sintering aid; the above-mentioned strontium source, titanium source, manganese source, metal oxide, sintering aid The molar ratio is 0.99:1.0085:0.0005:0.005:0.002; the strontium source is strontium titanate, the titanium source is titanium dioxide, and the manganese source is Mn(NO 3 ) 2 , the metal oxide is Nd with a molar ratio of 1:3 2 o 3 and Sb 2 o 3 , The sintering aid is a mixture of alumina, silicon dioxide, and zirconium dioxide in a molar ratio of 0.03:0.03:0.62.

[0044] The preparation method of the positive temperature coefficient thermosensitive material of the present embodiment comprises the following steps:

[0045] 1) Mixing

[0046] Strontium titanate, titanium dioxide, Nd with a molar ratio of 0.99:1.0085:0.0005:0.0015 2 o 3 , Sb 2 o 3 Put it into a ball m...

Embodiment 3

[0053] The positive temperature coefficient heat-sensitive material of this embodiment is made of the following raw materials: lead source, titanium source, manganese source, metal oxide, sintering aid; the above-mentioned lead source, titanium source, manganese source, metal oxide, sintering aid The molar ratio is 0.9915:1.0095:0.0004:0.002:0.001; wherein the lead source is lead titanate, the titanium source is titanium dioxide, and the manganese source is Mn(NO 3 ) 2 , the metal oxide is Nd with a molar ratio of 1:3 2 o 3 and Y 2 o 3 , The sintering aid is a mixture of alumina, silicon dioxide, and zirconium dioxide in a molar ratio of 0.03:0.03:0.62.

[0054] The preparation method of the positive temperature coefficient thermosensitive material of the present embodiment comprises the following steps:

[0055] 1) Mixing

[0056] Lead titanate, titanium dioxide, Nd with a molar ratio of 0.9915:1.0095:0.0005:0.0015 2 o 3 , Y 2 o 3 Put it into a ball mill, add water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com