Guide rod type hydraulic piling hammer

A hydraulic piling hammer and guide rod type technology, which is applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve problems that affect people's work and living environment, explosion vibration, pollution of guide rod diesel piling hammer, etc., to ensure Continuous high-efficiency work, reliable hammering guiding effect, flexible movement and good directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

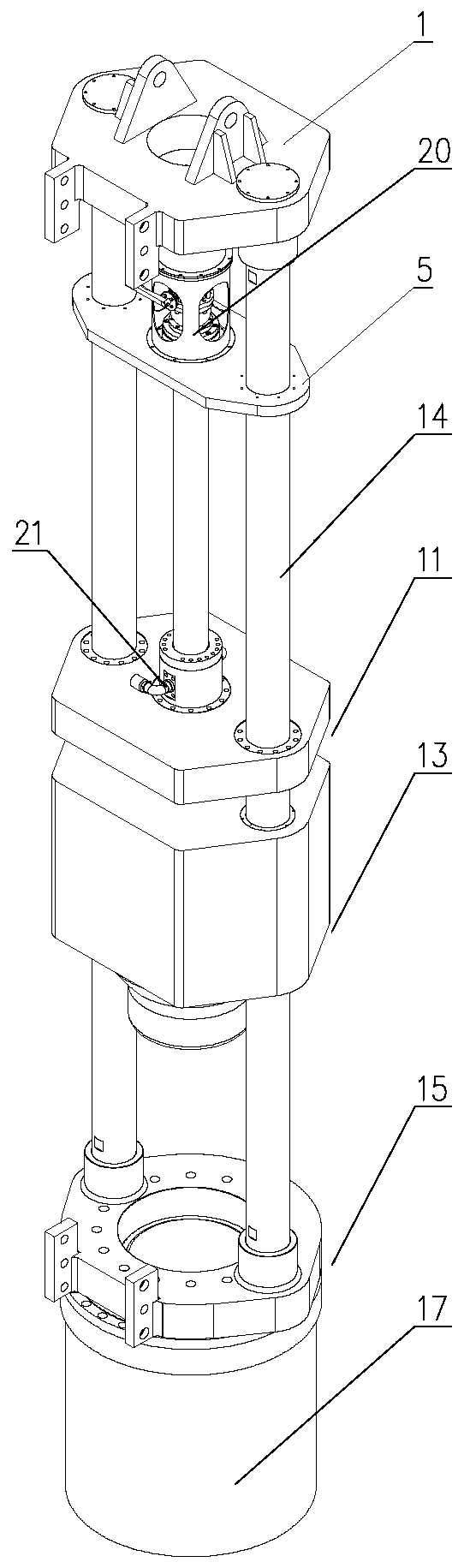

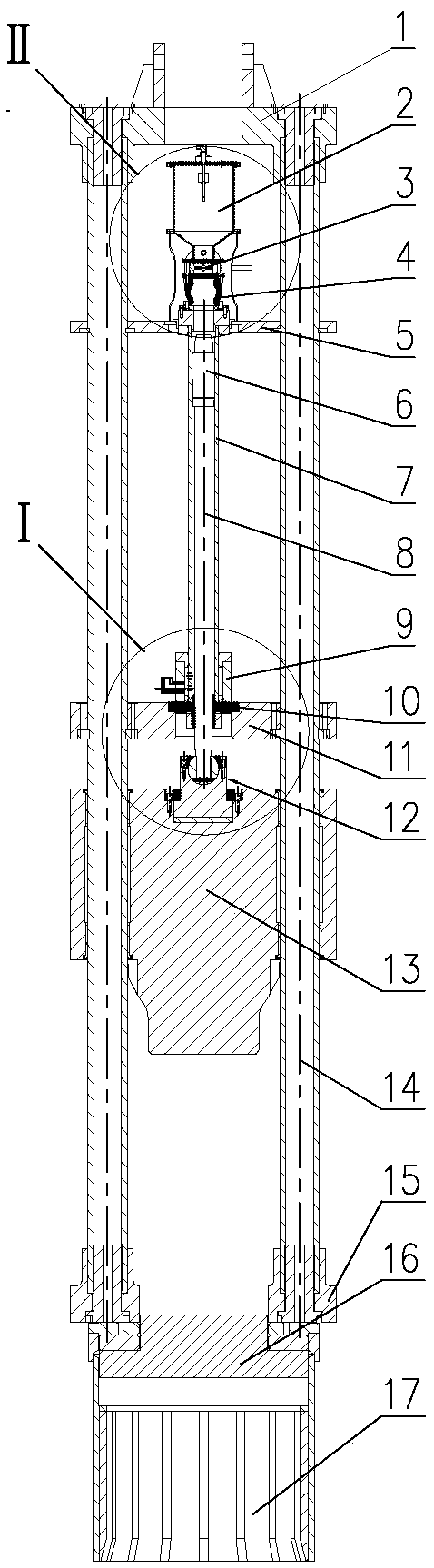

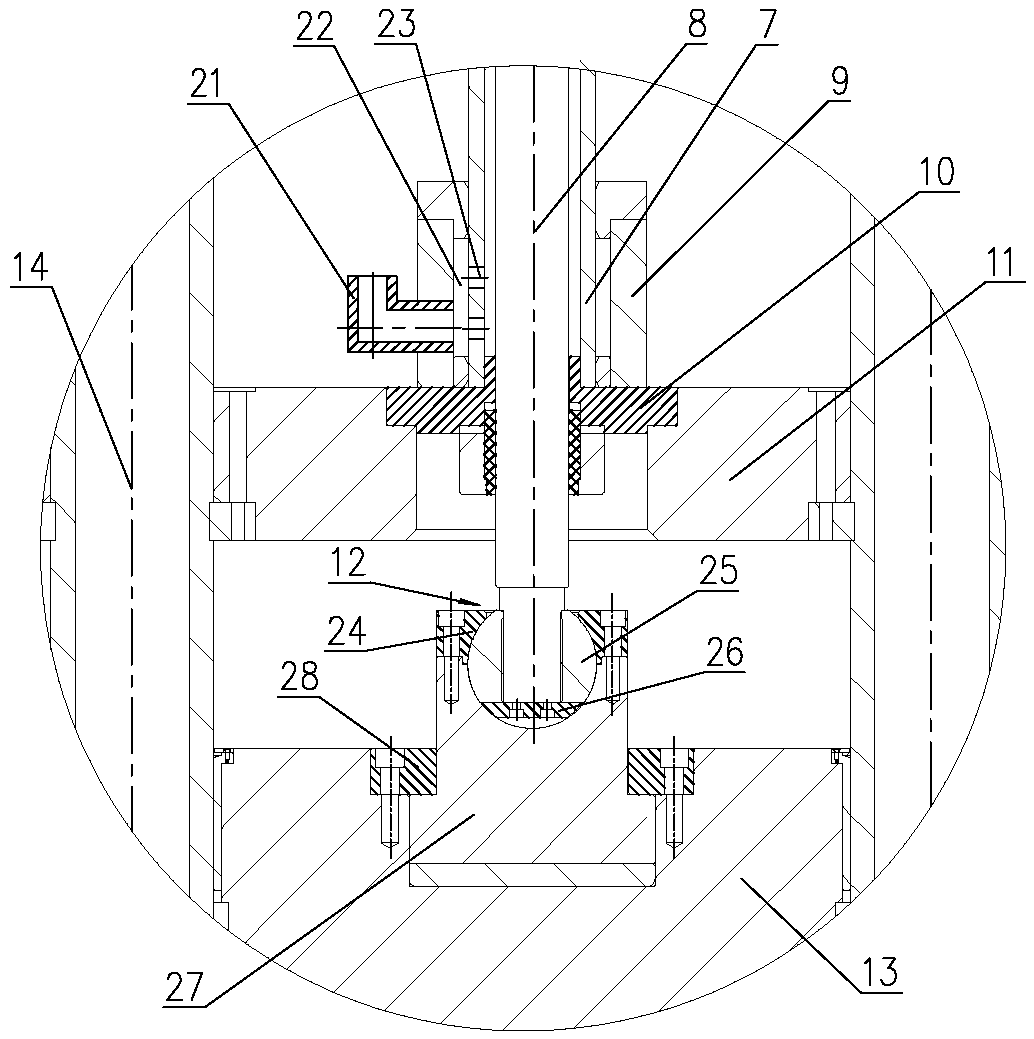

[0020] Such as figure 1 , figure 2 The guide rod type hydraulic piling hammer shown in the figure includes two guide rods 14 parallel to each other. The two guide rods 14 are cylindrical hollow tubes with the same outer diameter. The tube structure has high mechanical strength and rigidity. . An upper crossbeam 1 is fixedly connected to the top positions of the two guide rods 14, and two suspension ring ears are arranged on the upper crossbeam 1; a lower crossbeam 15, two guide rods 14 and the upper crossbeam are fixedly connected to the lower ends of the two guide rods 14. 14 and lower beam 15 constitute a stable frame structure. A pile cap 17 is also fixedly connected to the lower side of the lower crossbeam 15, and the pile cap 17 is set on the top of the pile during piling; a replacement block 16 is also movably arranged on the upper mouth of the pile cap 17, and the replacement block 16 is located on the lower crossbeam. The downside of 15, the impact pile hammer of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com