Deep ultraviolet light frequency doubling test device

A test device and deep ultraviolet light technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of attenuator opening cavity, frequent cavity opening, single attenuator setting, etc., to ensure repeatability, comparability, accuracy, The effect of small measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

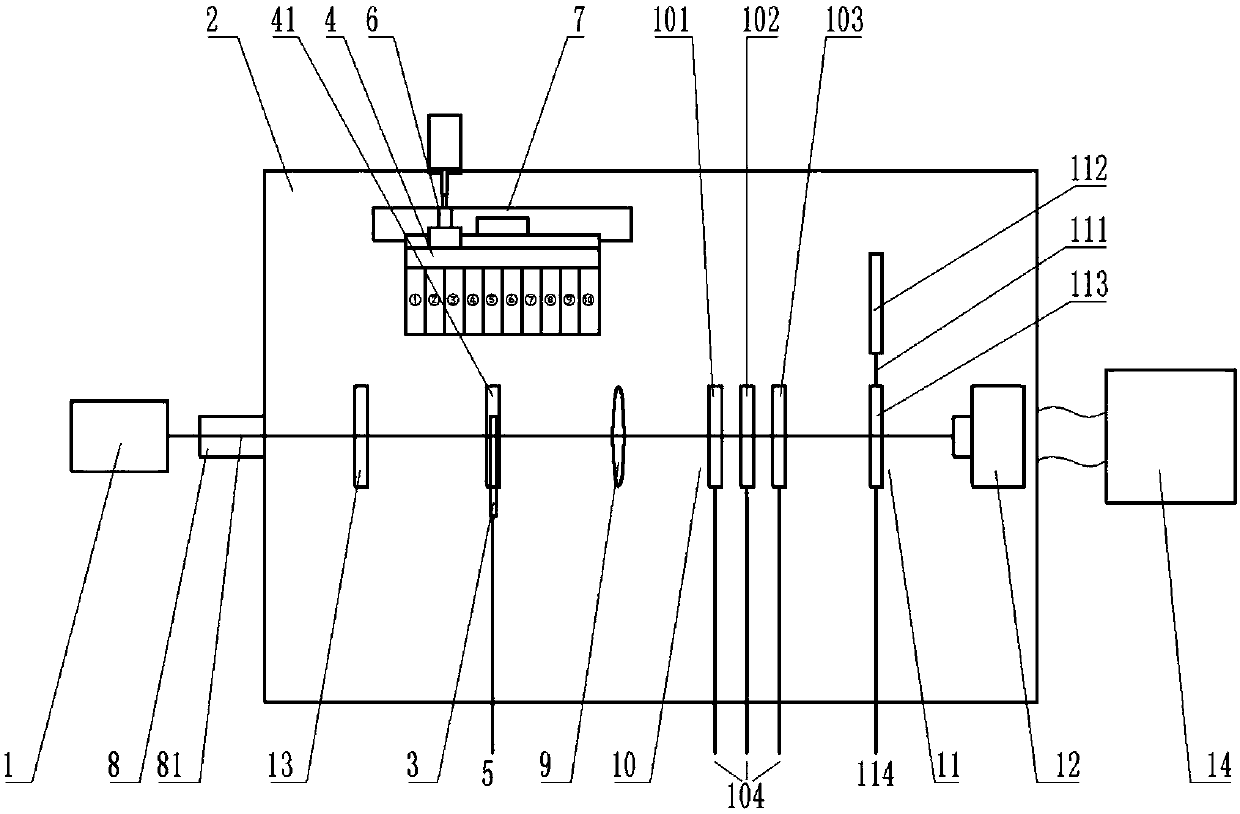

[0049] figure 1 It is a schematic diagram of the test device provided by Embodiment 1 of the present invention;

[0050] Please refer to figure 1 , This embodiment provides a deep ultraviolet light frequency doubling test device, including a light source 1, a closed dark room 2, a sample rack 3, a sample storage 4, and a sample control rod 5.

[0051] Wherein, the light source 1 is arranged at the entrance outside the airtight darkroom 2, and emits ultraviolet light into the airtight darkroom 2 to form a light path. In this embodiment, the light source 1 is an ultraviolet laser light source with a wavelength range of 290-370nm, and the frequency-doubled light generated after irradiating the sample is a deep ultraviolet laser. The wavelength range of the ultraviolet laser band described below is also the wavelength range of the light source 1. The wavelength range is 290nm-370nm, and the wavelength range of the corresponding deep ultraviolet laser, that is, the frequency-doub...

Embodiment 2

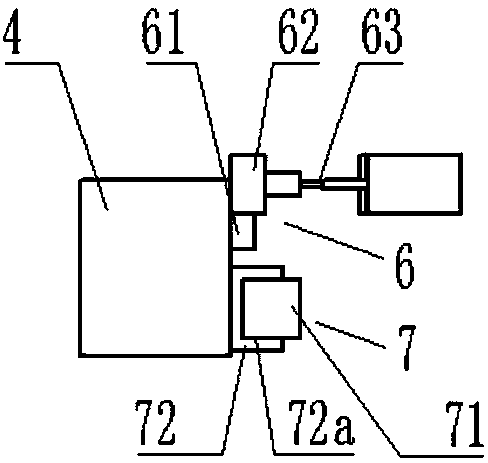

[0094] image 3 It is a schematic diagram of the structure and position of the transmission mechanism and the sliding mechanism provided by the second embodiment of the present invention.

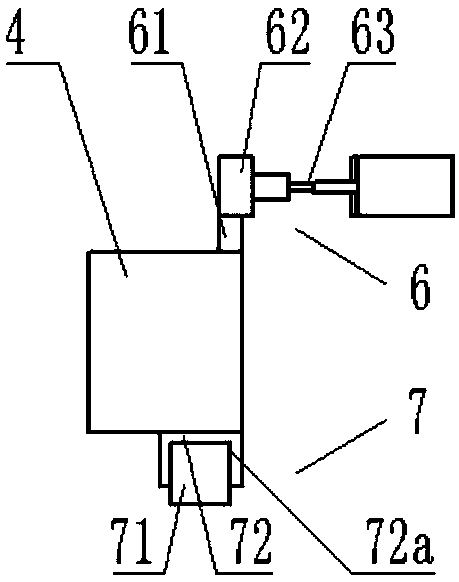

[0095] The difference between this embodiment and the first embodiment lies in that the positions of the transmission mechanism 6 and the sliding mechanism 7 are different.

[0096] Please refer to image 3 , In this embodiment, the rack 61 is arranged on the top surface of the sample library 4 with the tooth surface facing upward. The slide block 72 is arranged on the bottom surface of the sample storage 4, located above the slide rail 71, and is slidably connected with the slide rail 71 through the slide groove 72a. The gear 62 rotates under the drive of the transmission shaft 63, and drives and guides the sample library 4 to move along the slide rail 71 through the rack 61 and the slide block 72, so that the sample boxes 41 of different numbers correspond to the positions of the sample...

Embodiment 3

[0099] The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the sample library 4 is fixed in the airtight darkroom 2 and does not move, and the end of the sample control rod 5 extending out of the airtight darkroom 2 is connected with the control end, and is set to be in the airtight darkroom 2. Move parallel to the optical path under the control of the end.

[0100] In this embodiment, the sliding mechanism 7 is connected to the sample control rod 5, and a second positioning component is arranged on the sliding mechanism 7, so that the sample control rod 5 stops at a preset position during the movement process. The preset position here refers to different When the numbered sample box 41 corresponds to the position of the sample rack 3, the position of the sample control rod 5 is located.

[0101] Specifically, the control terminal controls the sample control rod 5 to move in a direction parallel to the optical path, and the sample control rod 5 driv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com