A kind of graphene-rubber and its preparation method and application

A graphene and rubber technology, applied in the field of composite materials, can solve problems such as impossible to obtain real practical effects, and achieve the effects of high tension, high sensitivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

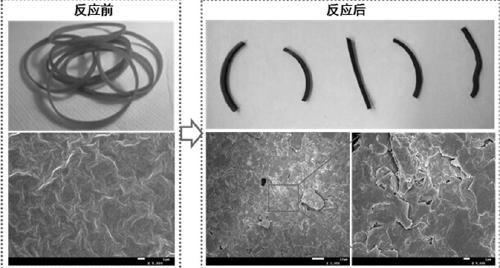

[0033] A kind of graphene-rubber preparation method, comprises the following steps:

[0034] step one:

[0035] Take by weighing 300mg graphite powder, 200mgPVP (polyvinylpyrrolidone) is dissolved in the mixed solvent that 2ml ethanol and 8ml deionized water form;

[0036] Step two:

[0037] The mixed solution was sealed and sonicated for 24h (240W, T<25°C), then centrifuged (1500r / min, 45min), and the supernatant was taken out;

[0038] Step three:

[0039] The supernatant obtained in the previous step was centrifuged again at a speed of 10,000 r / min for 15 minutes, and the obtained precipitate was washed once with ethanol and taken out, and dried at 60° C. to obtain a dry powder that was graphene;

[0040] Step four:

[0041] Cut out a rubber band with a length of about 4cm and a side diameter of about 1.5mm, after accurately weighing it, soak it in a certain amount of toluene (just immerse the rubber band) and ultrasonicate for 3 hours (240W, T<25°C);

[0042] Step fiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com