Tencel, combed long-staple cotton and ramie blended yarn and production method and application thereof

A production method and technology of long-staple cotton, which is applied in the fields of combed long-staple cotton, ramie blended yarn, and Tencel, which can solve the problems of difficult control of production costs, itching, high noil rate, etc., and overcome the difficulties in the production process , to ensure the uniformity of mixing, to overcome the effect of poor taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

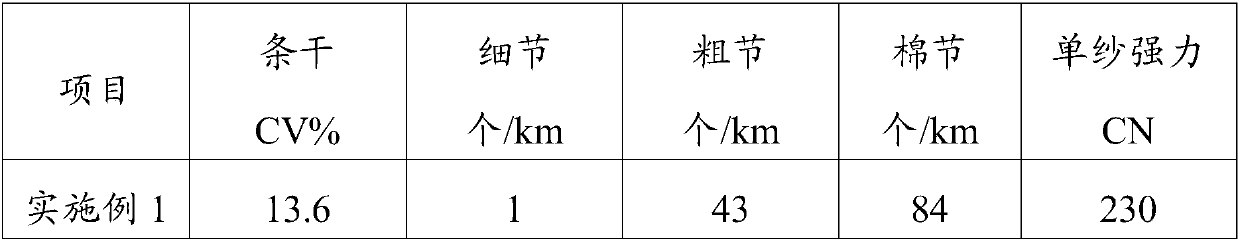

Examples

Embodiment 1

[0028] A kind of preparation above-mentioned tencel, combed long-staple cotton, ramie blended yarn, its preparation method is as follows:

[0029] S1. Take tencel fiber, combed long-staple cotton fiber and ramie fiber according to the weight ratio of 45:43:12, and divide the combed long-staple cotton fiber into two parts of 25:18 by weight, and the heavier part is made into refined Comb long-staple cotton slivers, the lighter part is mixed with ramie fibers to make combed long-staple cotton and ramie mixed slivers, and tencel fibers are made into tencel slivers;

[0030] S2. The combed long-staple cotton sliver, combed long-staple cotton and ramie mixed sliver and tencel sliver obtained in S1 are processed through drawing process to obtain mixed cooked sliver of tencel, combed long-staple cotton and ramie , and then through the roving process, the spinning process and the winding process in sequence to obtain the blended yarns of tencel, combed long-staple cotton and ramie.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com