Noise comprehensive treatment system for gas-driven generator set and distributed energy station

A technology for distributed energy and comprehensive treatment, applied in the field of gas-fired units and distributed energy station noise comprehensive treatment systems, can solve problems affecting the health, living and working conditions of surrounding people, industrial noise pollution and noise pollution in the surrounding environment, etc. Beneficial for sound source monitoring, for noise assessment, reduction and noise pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

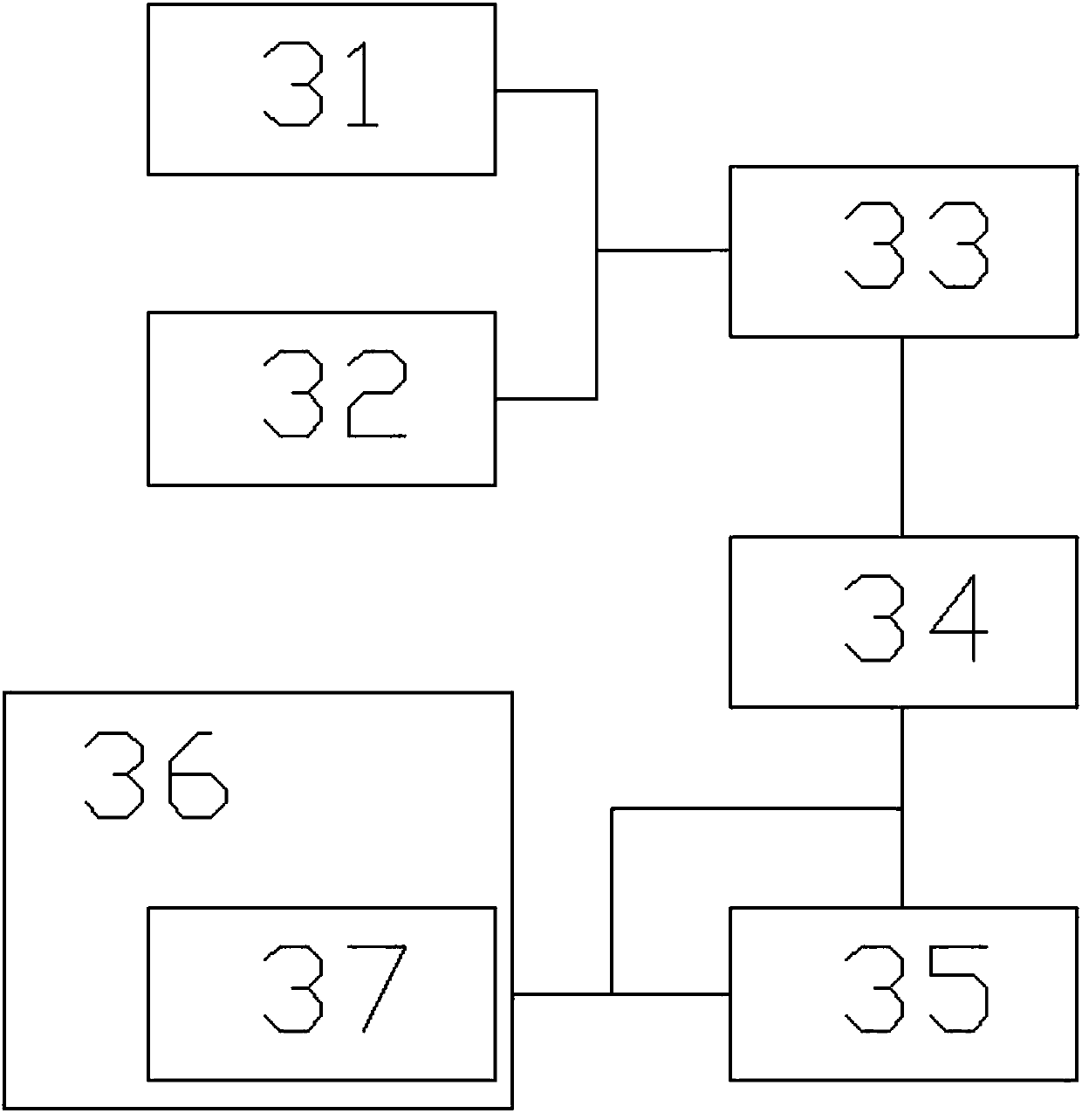

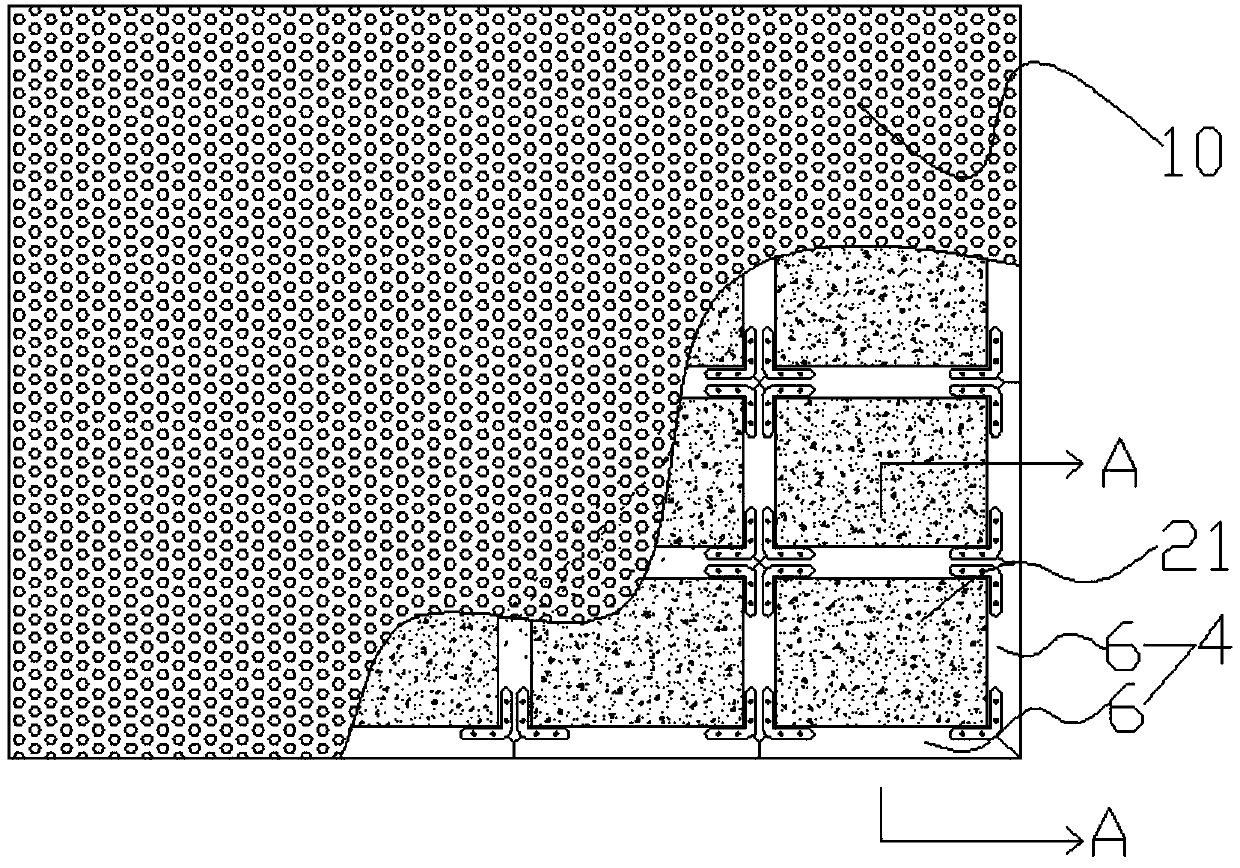

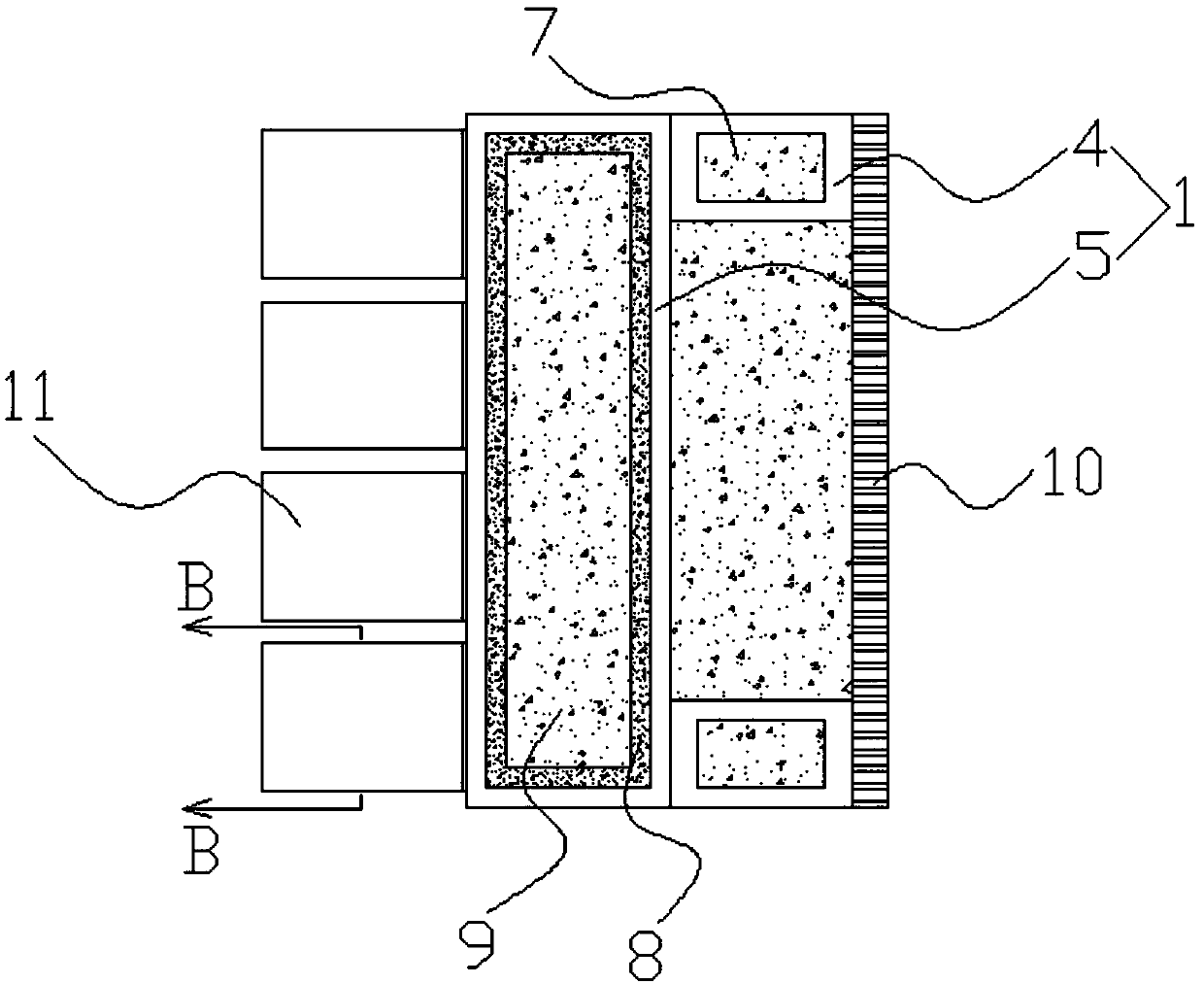

[0025] As shown in the figure, a gas-fired unit and a distributed energy station noise comprehensive control system, including a sound source monitoring system and noise comprehensive control equipment, is characterized in that the sound source monitoring system includes a camera 31, a sound level meter 32, a signal Conversion module 33, wireless communication module 34, wireless repeater 35 and control center 36, described camera 31 is a rotatable pan-tilt camera, and it is integrated with sound level meter 32, and the photographing direction of camera 31 and sound level meter 32 detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com