Front triangular welding fixture of titanium alloy bicycle

A technology for welding tooling and bicycles, applied in welding equipment, welding accessories, auxiliary welding equipment, etc., can solve the problems of high cost, poor operability, poor welding quality, etc., achieve easy operation, strong practicability, and improve weld quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

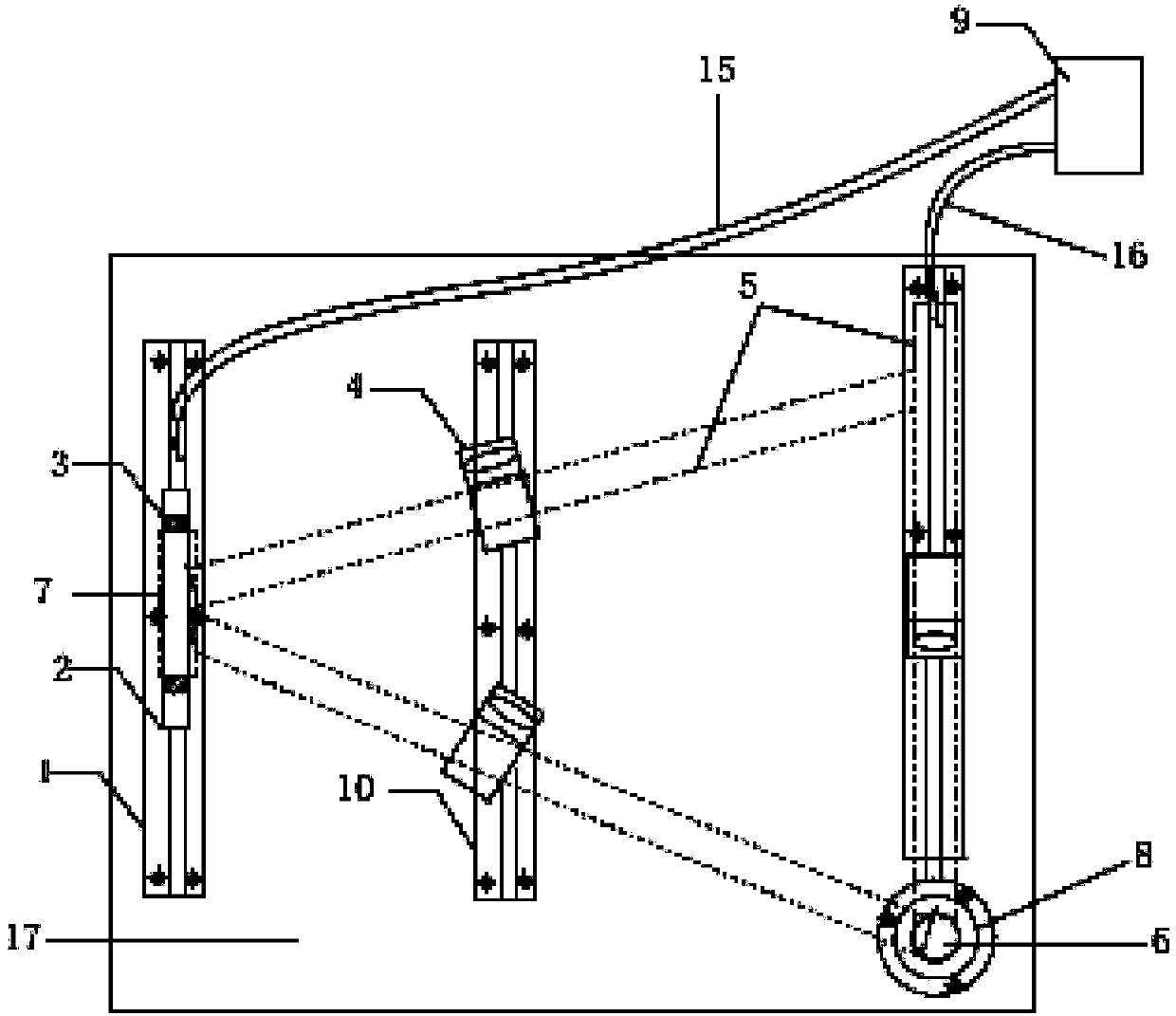

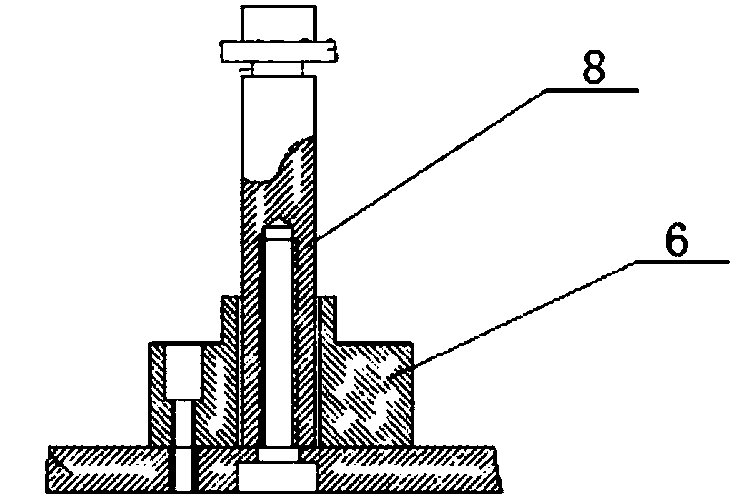

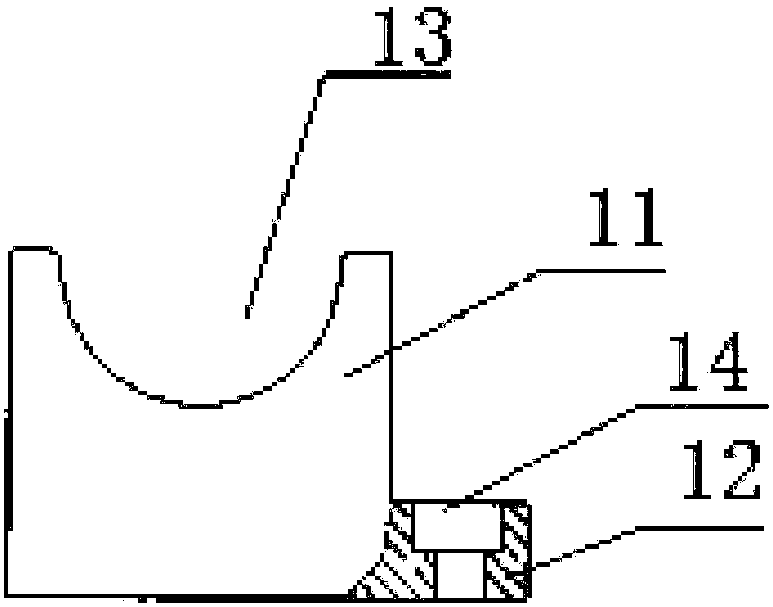

[0016] The welding frock structure of the front triangle of a titanium alloy bicycle provided by the invention is as follows: figure 1 As shown, it includes a bottom plate 17, a fixed plate 1, a support plate 10 and a positioning device, wherein the fixed plate 1 is fixed on the bottom plate 17 with bolts. Two support plates 10 are arranged parallel to the direction perpendicular to the fixing plate 1, and are used to support the titanium alloy tube 5 of the bicycle front tripod. Each titanium alloy tube 5 and the support plate 10 are provided with a tube spacer 4 at the junction of each titanium alloy tube 5, which is used to support and fix the The titanium alloy pipe 5 and the pipe spacer 4 are composed of a spacer a11 and a connecting block 12. The spacer b11 is provided with a groove 13 which is consistent with the diameter of the titani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com