Nanometer barium phosphate modified polymer sulfoaluminate cement-based marine corrosion-resistant coating and preparation method thereof

A sulfoaluminate cement and sulfoaluminate technology, applied in anti-corrosion coatings, cement coatings, coatings, etc., can solve the problem of weather resistance, seawater erosion resistance, poor scour resistance, insufficient interface bond strength, and sulfate erosion resistance. Poor performance and other problems, to achieve good waterproof and anti-corrosion performance, improve waterproof, anti-corrosion and impermeability, and reduce porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

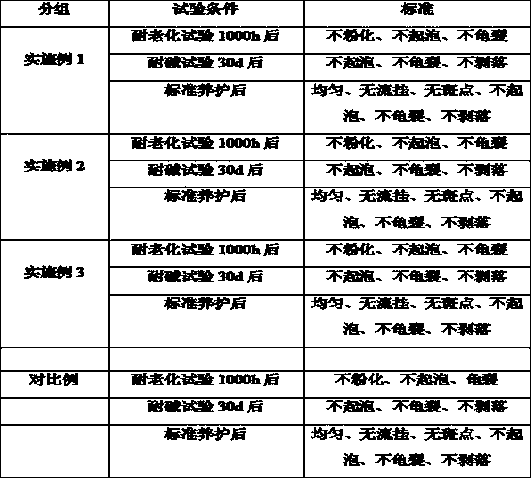

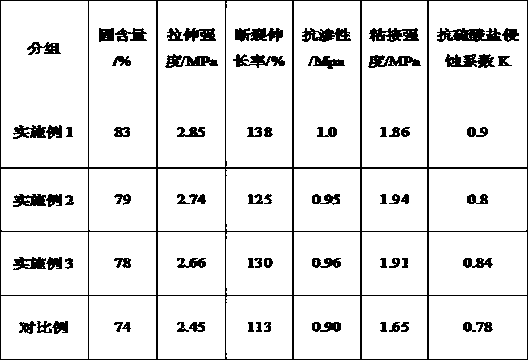

Examples

Embodiment 1

[0028] A polymer sulphoaluminate cement-based marine anti-corrosion coating modified by nano-barium phosphate is prepared from the following raw materials in parts by weight: 60 parts of sulphoaluminate cement, 40 parts of fly ash, and 20 parts of silicon dioxide , 80 parts of silicone modified polyacrylate emulsion, 20 parts of water, 1 part of water reducer, 0.5 part of defoamer, 3 parts of dispersant, 1 part of film-forming aid.

[0029] The cement is early-strength and fast-hardening 42.5 sulfoaluminate cement; the water reducer is polycarboxylate water reducer; the dispersant is sodium hexametaphosphate; the film-forming aid is 2, 2,4-trimethyl-1,3-pentanediol monoisobutyrate; the defoamer is a silicone defoamer.

[0030] A preparation method of polymer sulphoaluminate cement-based marine anticorrosion coating modified by nanometer barium phosphate is prepared by the following steps:

[0031] 1) Preparation of vinyl-containing nanobarium phosphate:

[0032] Magnetically...

Embodiment 2

[0044] A polymer sulphoaluminate cement-based marine anti-corrosion coating modified by nano-barium phosphate is prepared from the following raw materials in parts by weight: 70 parts of sulphoaluminate cement, 30 parts of fly ash, and 25 parts of silicon dioxide , 60 parts of silicone modified polyacrylate emulsion, 30 parts of water, 3 parts of water reducer, 1 part of defoamer, 2 parts of dispersant, 3 parts of film-forming aid.

[0045] The cement is early-strength and fast-hardening 42.5 sulfoaluminate cement; the water reducer is polycarboxylate water reducer; the dispersant is sodium hexametaphosphate; the film-forming aid is 2, 2,4-trimethyl-1,3-pentanediol monoisobutyrate; the defoamer is a silicone defoamer.

[0046] A preparation method of polymer sulphoaluminate cement-based marine anticorrosion coating modified by nanometer barium phosphate is prepared by the following steps:

[0047] 1) Preparation of vinyl-containing nanobarium phosphate:

[0048] Magnetically...

Embodiment 3

[0060] A polymer sulphoaluminate cement-based marine anti-corrosion coating modified by nano-barium phosphate, which is prepared from the following raw materials in parts by weight: 80 parts of sulphoaluminate cement, 20 parts of fly ash, and 30 parts of silicon dioxide , 40 parts of silicone modified polyacrylate emulsion, 40 parts of water, 5 parts of water reducer, 2 parts of defoamer, 1 part of dispersant, 5 parts of film-forming aid.

[0061] The cement is early-strength and fast-hardening 42.5 sulfoaluminate cement; the water reducer is polycarboxylate water reducer; the dispersant is sodium hexametaphosphate; the film-forming aid is 2, 2,4-trimethyl-1,3-pentanediol monoisobutyrate; the defoamer is a silicone defoamer.

[0062] A preparation method of polymer sulphoaluminate cement-based marine anticorrosion coating modified by nanometer barium phosphate is prepared by the following steps:

[0063] 1) Preparation of vinyl-containing nanobarium phosphate:

[0064] Magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com